Correction method and circuit of AC load power factor

A technology of power factor and AC load, applied in the direction of reactive power adjustment/elimination/compensation, reactive power compensation, etc., can solve problems such as unable to correct AC load power factor, not yet found AC load, limited application range, etc., to achieve obvious Economic and social benefits, low loss, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

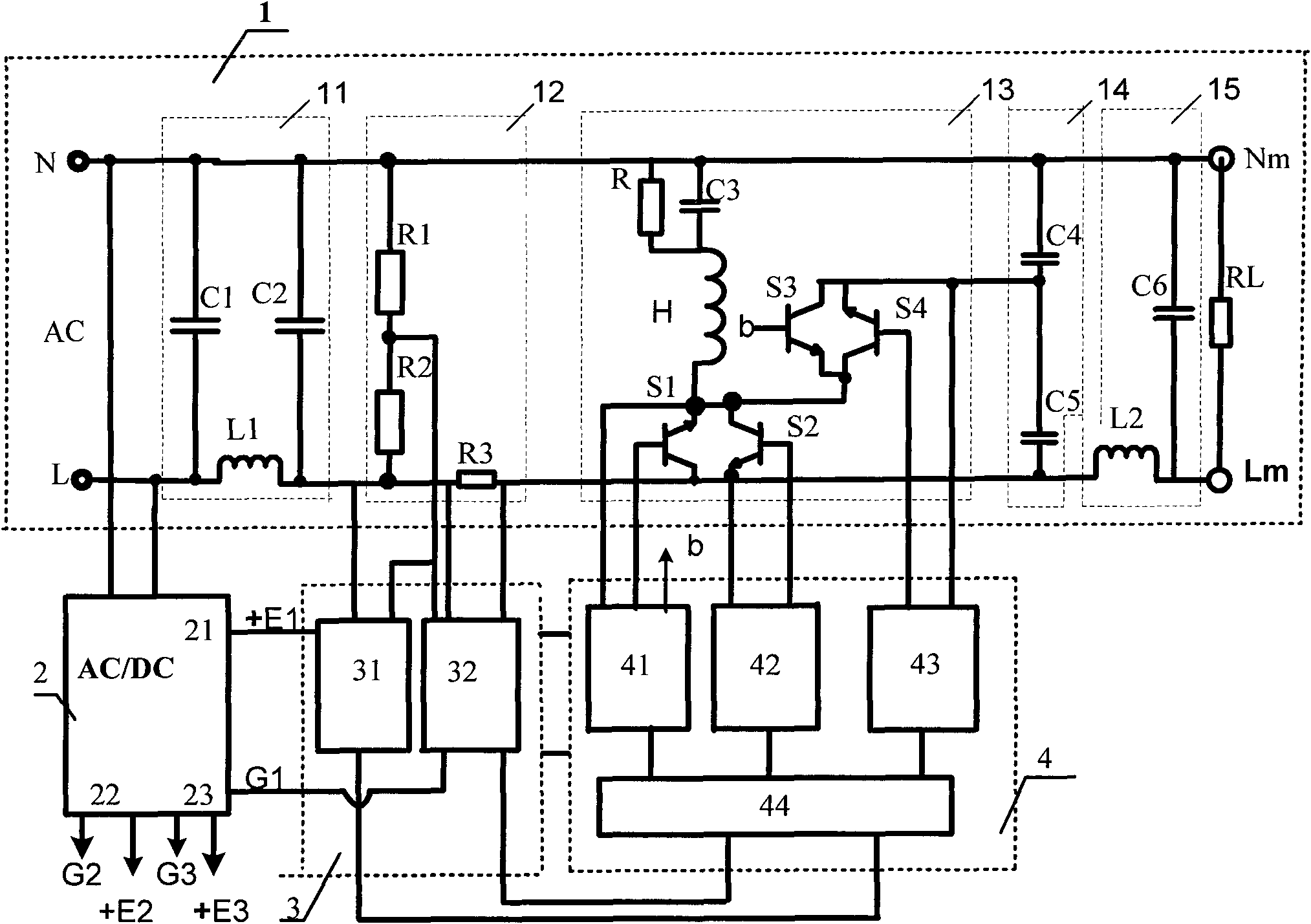

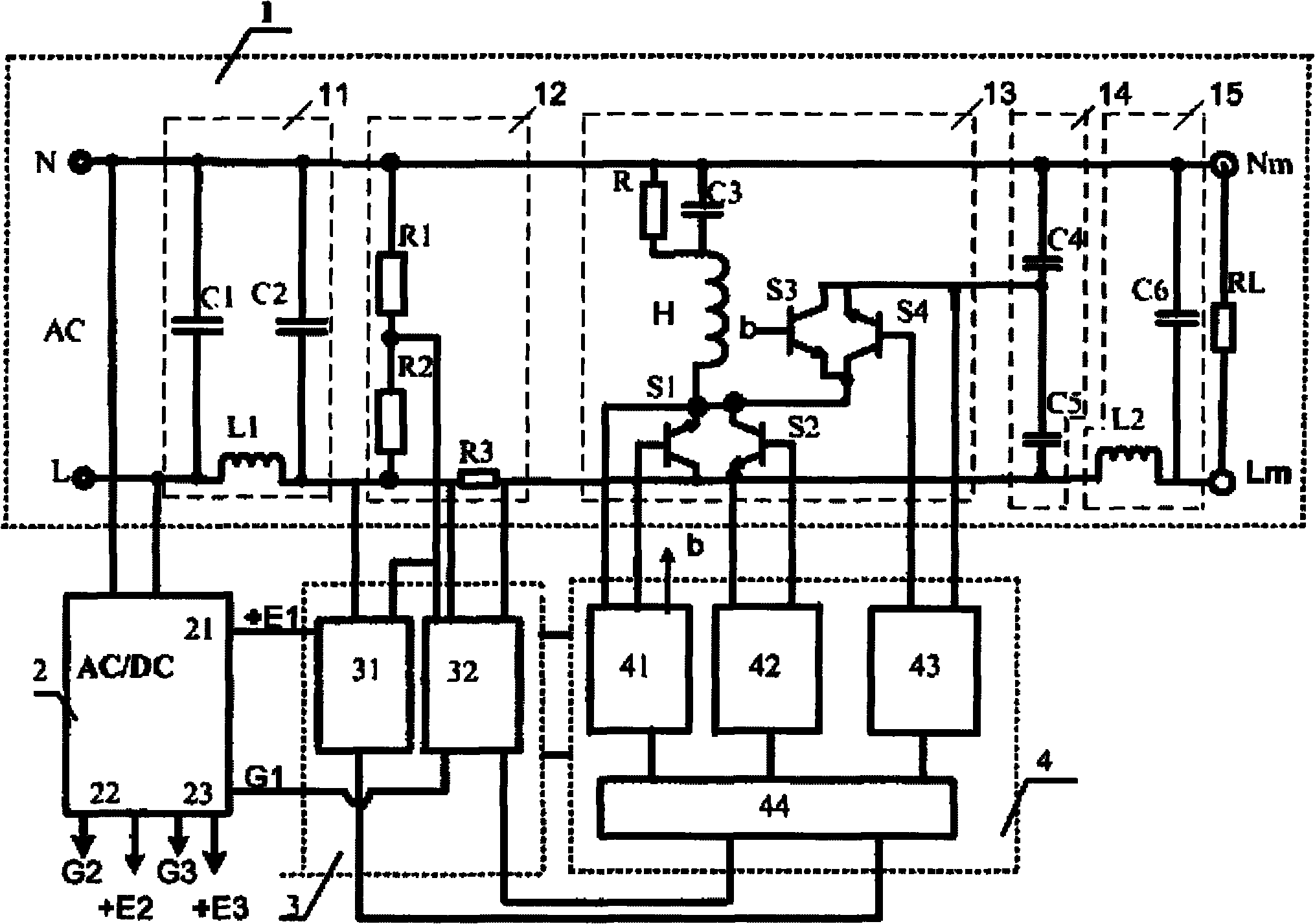

[0029] The specific design of the calibration method and circuit in this embodiment is as follows: the calibration method and circuit mainly include an AC calibration main circuit 1 , an AC / DC multi-channel DC stabilized power supply 2 , a detection circuit 3 and a control circuit 4 . The AC correction main circuit 1 includes an input filter circuit 11 composed of an AC input terminal L and a common terminal N, an input filter capacitor C1, an input filter inductor L1 and a filter capacitor C2; the voltage detection resistors R1 and R2, the current detection resistor A voltage and current detection circuit 12 composed of R3; a conversion circuit composed of a charging and discharging capacitor C3, two charging switching elements S1 and S2, two discharging switching elements S3 and S4, and an inductance H; a circuit consisting of an absorbing capacitor C4 and a coupling capacitor C5 Bootstrap circuit 14; the output filter circuit 15 that is made up of output filter inductance L2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com