Membrane separation concentrated water treatment method and integral coupling device

A treatment device and treatment method technology, which is applied in the treatment device coupled with ultrasonic technology and membrane separation technology, membrane separation concentrated water treatment, and photocatalytic oxidation, can solve the problems of high cost and low efficiency of inorganic membrane separation, and achieve Small footprint, improved sewage treatment capacity and treatment effect, and the effect of reducing membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

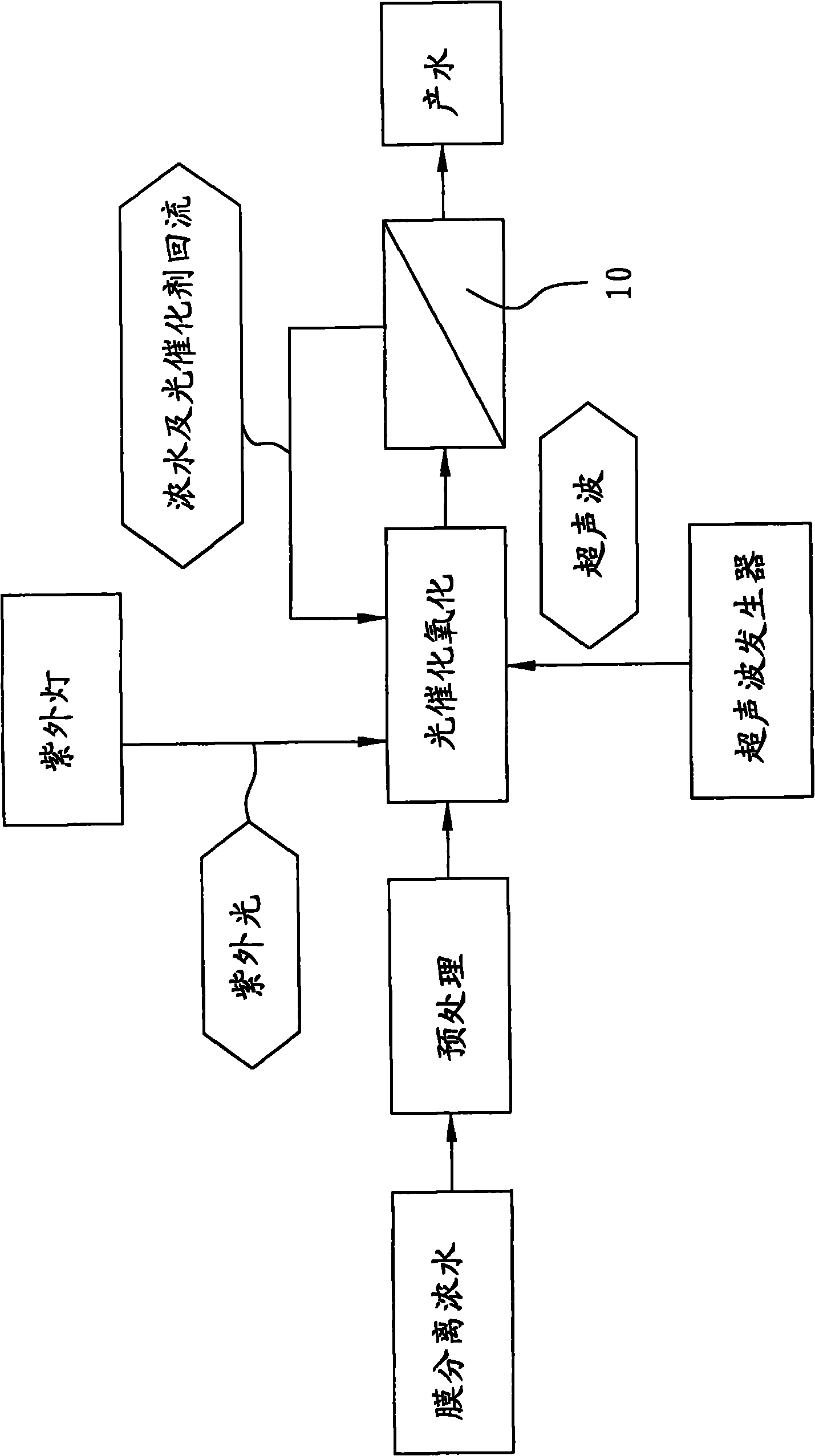

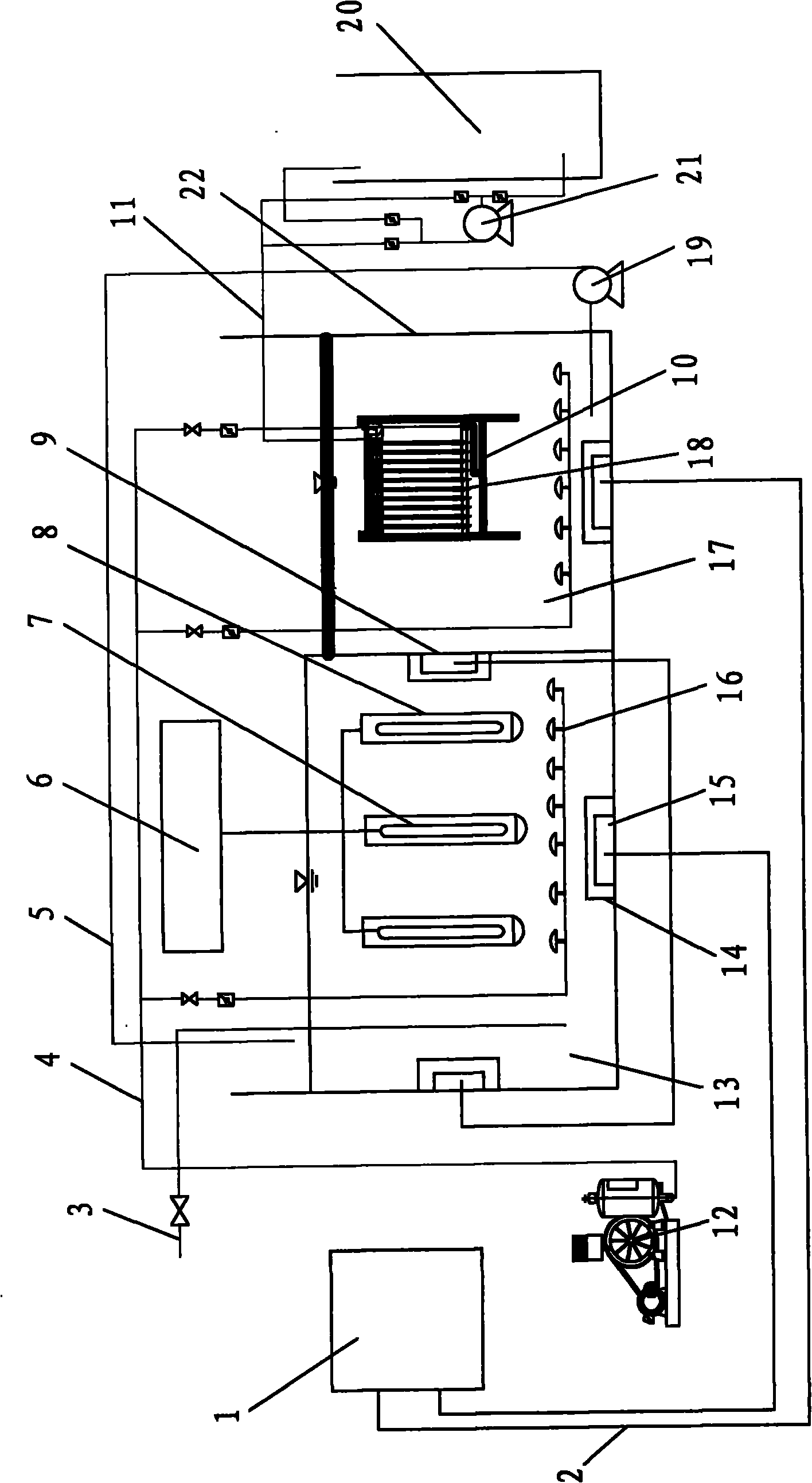

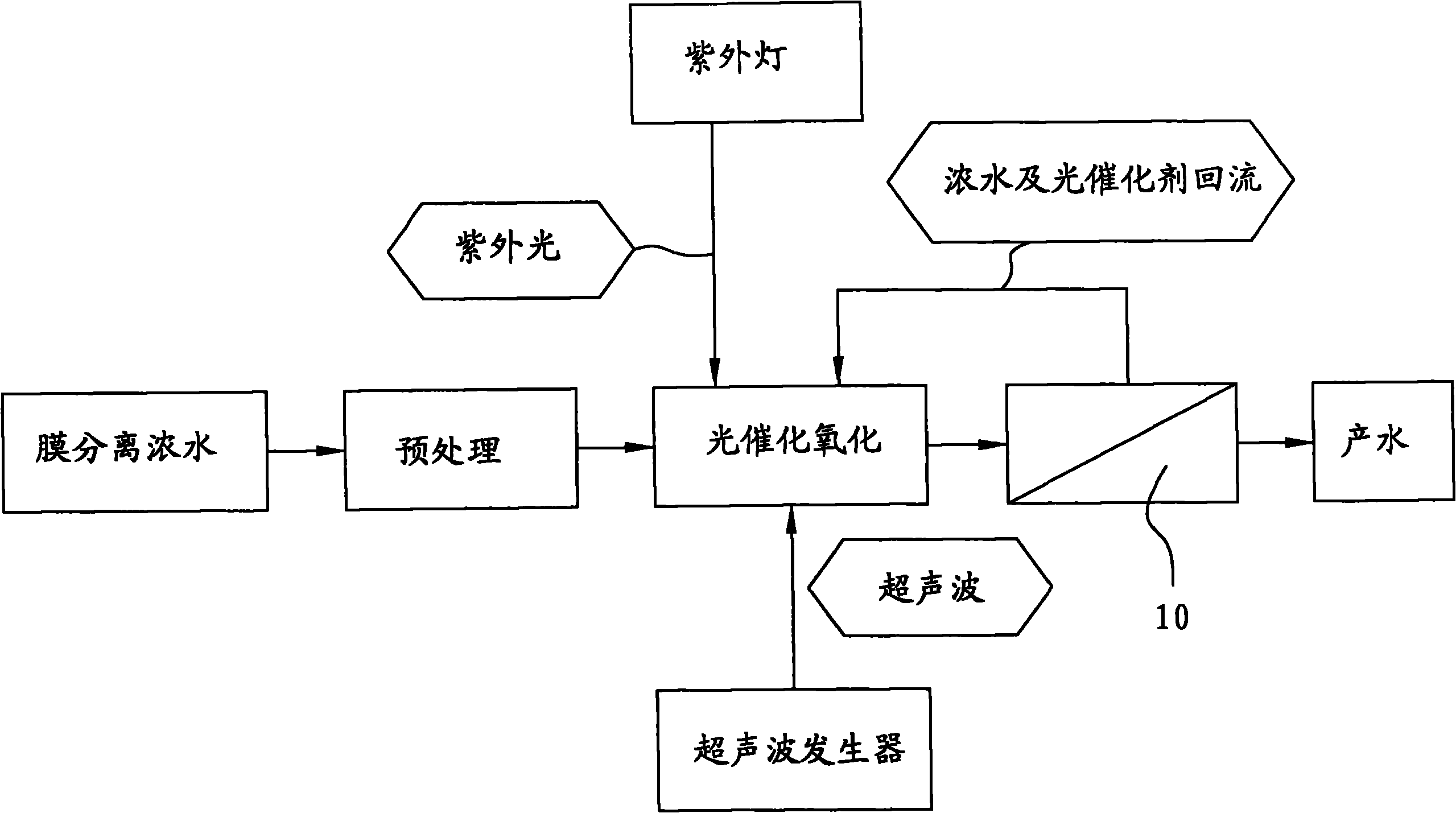

[0032] Example 1: See figure 1 , the sewage to be treated is concentrated water from membrane separation in the printing and dyeing industry, of which COD 240, BOD 50, and TiO used 2 The average particle size of the particles is 0.2-0.3μm, TiO 2 The concentration is 2g / L, the submerged ultrafiltration membrane is made of PVDF, and the pore size is 0.01μm. The treatment process is as follows:

[0033] (1) Membrane separation concentrated water enters the suspension photocatalytic reactor after pretreatment, and a large amount of photocatalytic reactant TiO is added to the photocatalytic reactor 2 Particles undergo photocatalytic reaction under the irradiation of ultraviolet light. At the same time, an ultrasonic generator is installed in the photocatalytic reaction pool. Through the synergistic effect of photocatalysis and ultrasonic waves, the degradation rate and degradation effect of pollutants are improved;

[0034] (2) Wastewater treated by photocatalytic oxidation and u...

Embodiment 2

[0039] Example 2: See figure 1 and figure 2 , the sewage to be treated is concentrated water from membrane separation in the printing and dyeing industry, of which COD 300, BOD 60, and TiO used 2 The average particle size of the particles is 0.2-0.3μm, TiO 2 The concentration is 1g / L, the submerged ultrafiltration membrane material is PVC, and the pore size is 0.1 μm. The process and equipment for the treatment are the same as those in Example 1, and will not be repeated here.

[0040] After measuring the COD 80 and BOD 40 of the product water, no photocatalyst TiO can be detected in the product water 2 The existence of the photocatalytic TiO 2 is completely blocked.

Embodiment 3

[0041] Example 3: See figure 1 and figure 2 , the sewage to be treated is concentrated water from membrane separation in the printing and dyeing industry, of which COD 200, BOD 50, and TiO used 2 The average particle size of the particles is 0.2-0.3μm, TiO 2 The concentration is 3g / L, the material of the submerged ultrafiltration membrane is PES, and the pore size is 0.001 μm. The process and equipment for the treatment are the same as those in Example 1, and will not be repeated here. The material of the above-mentioned submerged ultrafiltration membrane is PES and can also be replaced with PAN.

[0042] After measuring the COD 50 and BOD 30 of the product water, no photocatalyst TiO can be detected in the product water 2 The existence of the photocatalytic TiO 2 is completely blocked.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com