Micro wave drying method for grape seed proanthocyanidin extract

A proanthocyanidin and microwave drying technology, which is applied in the direction of organic chemistry, can solve the problems of high energy consumption and production cost, unsuitability for large-scale industrial production, and affecting product yield and quality. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

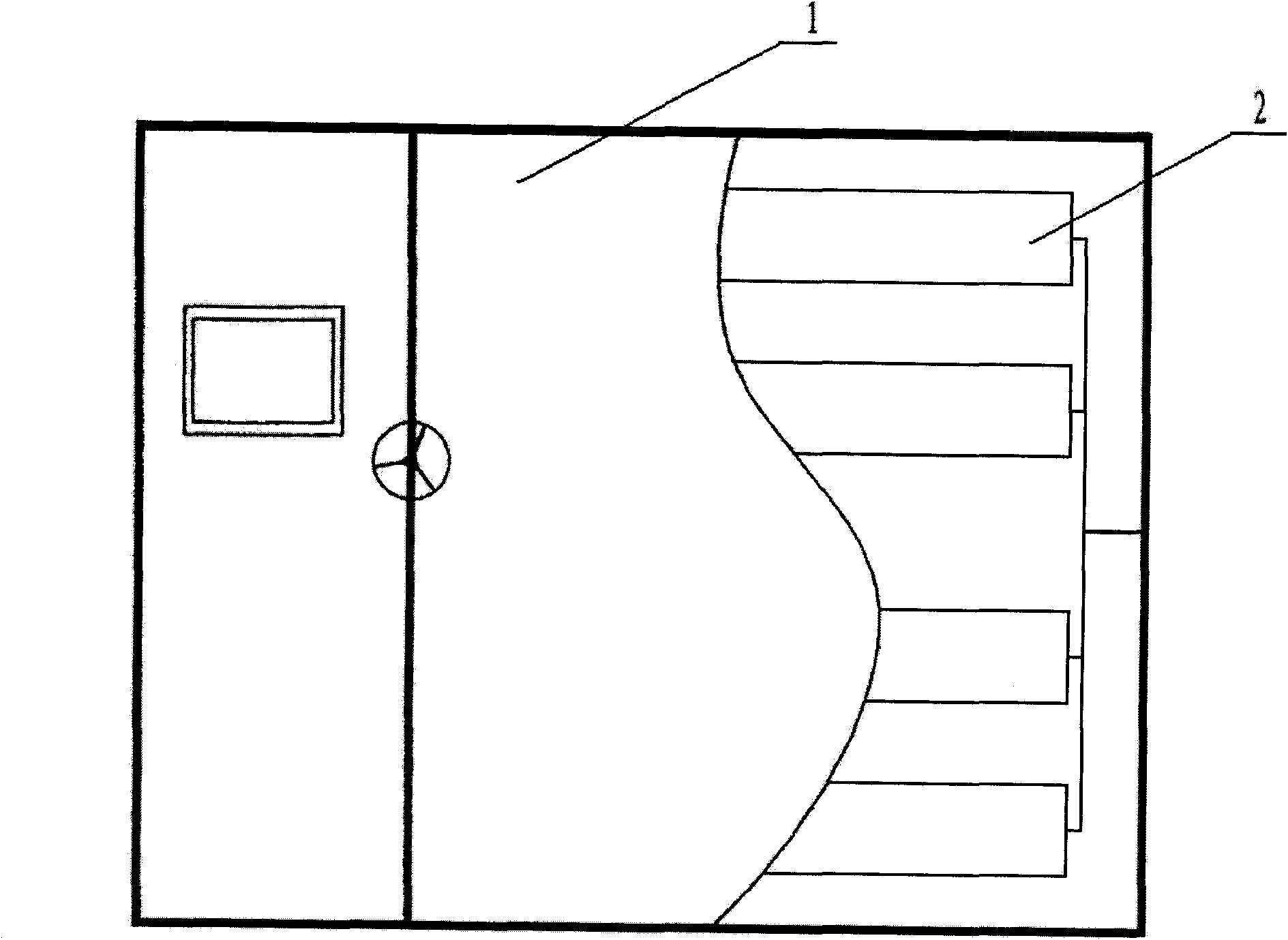

[0013] see figure 1 , the density is 1050kg / m 3 The proanthocyanidin extract was poured into four material boxes 2 of a vacuum microwave drying apparatus (KMZ-2000, Wenzhou Kangpai Pharmaceutical Machinery Co., Ltd.), and the sample loading capacity of each material box was about 160g. Close the door 1 to start vacuuming and make the four material boxes rotate at a constant speed. When the vacuum degree in the drying chamber is 0.02Mp, turn on the microwave. Red, porous, crispy dry extract, just scrape the dry extract from the material box. The moisture content of the dry extract is 3.74%, and the drying speed is 1.69kg / h.

Embodiment 2

[0015] see figure 1 , the density is 1150kg / m 3 Proanthocyanidin extract is poured into four material boxes 2 of the vacuum microwave drying instrument, and the sample loading capacity of each material box is 110g. Close the box door 1 to start vacuuming and make the four material boxes rotate at a uniform speed. When the vacuum degree in the drying chamber Turn on the microwave when it is 0.02Mp, the power of the microwave is 2000kW, the frequency of microwave emission is 2450MHz, and dry for 15 minutes to form a dark red, porous, crisp dry extract, which can be scraped off from the material box. The moisture content of the dry extract is 3.60%, and the drying speed is 1.04kg / h.

Embodiment 3

[0017] see figure 1 , the density is 1250kg / m 3 The proanthocyanidin extract is poured into four material boxes 2 of the vacuum microwave drying instrument, and the sample loading capacity of each material box is 70g. Close the box door 1 to start vacuuming and make the four material boxes rotate at a uniform speed. When the vacuum degree in the drying chamber Turn on the microwave when it is 0.02Mp, the power of microwave is 3000kW, the frequency of microwave emission is 2450MHz, and dry for 15 minutes to form a dark red, porous, crisp dry extract, which can be scraped off from the material box. The moisture content of the dry extract is 0.94%, and the drying speed is 0.56kg / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com