Composite fiber detection module and device

A composite optical fiber and detection module technology, which is applied in the direction of measuring devices, optical devices, fiber mechanical structures, etc., can solve the problems of difficult to achieve large range and orientation determination, poor TDR sensitivity, and small optical signal loss, etc., and achieve good monitoring effect , small transmission loss, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

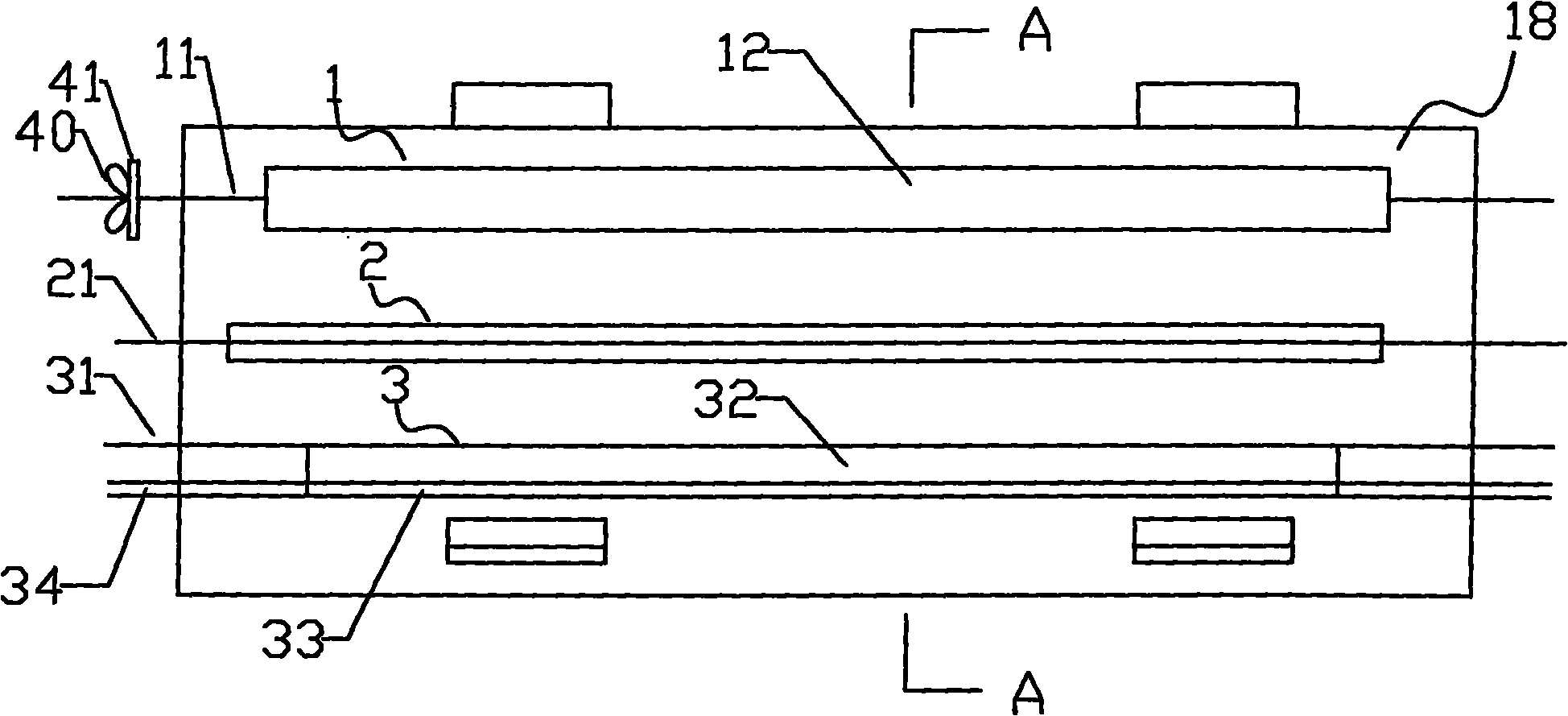

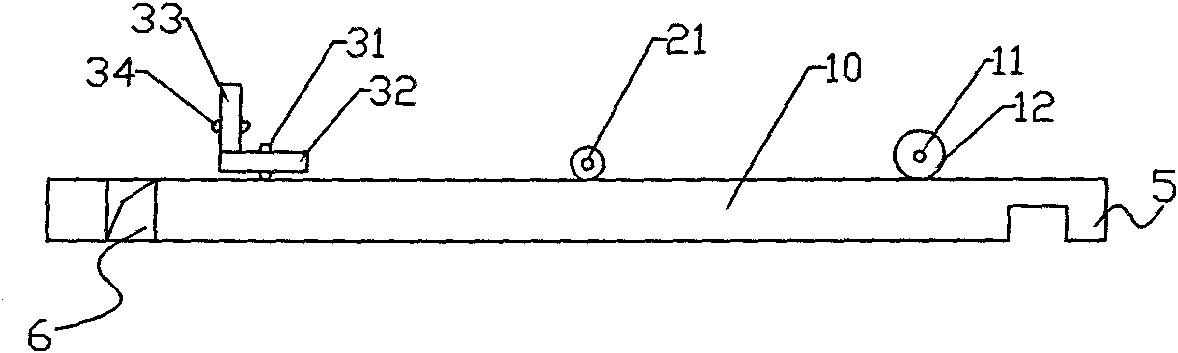

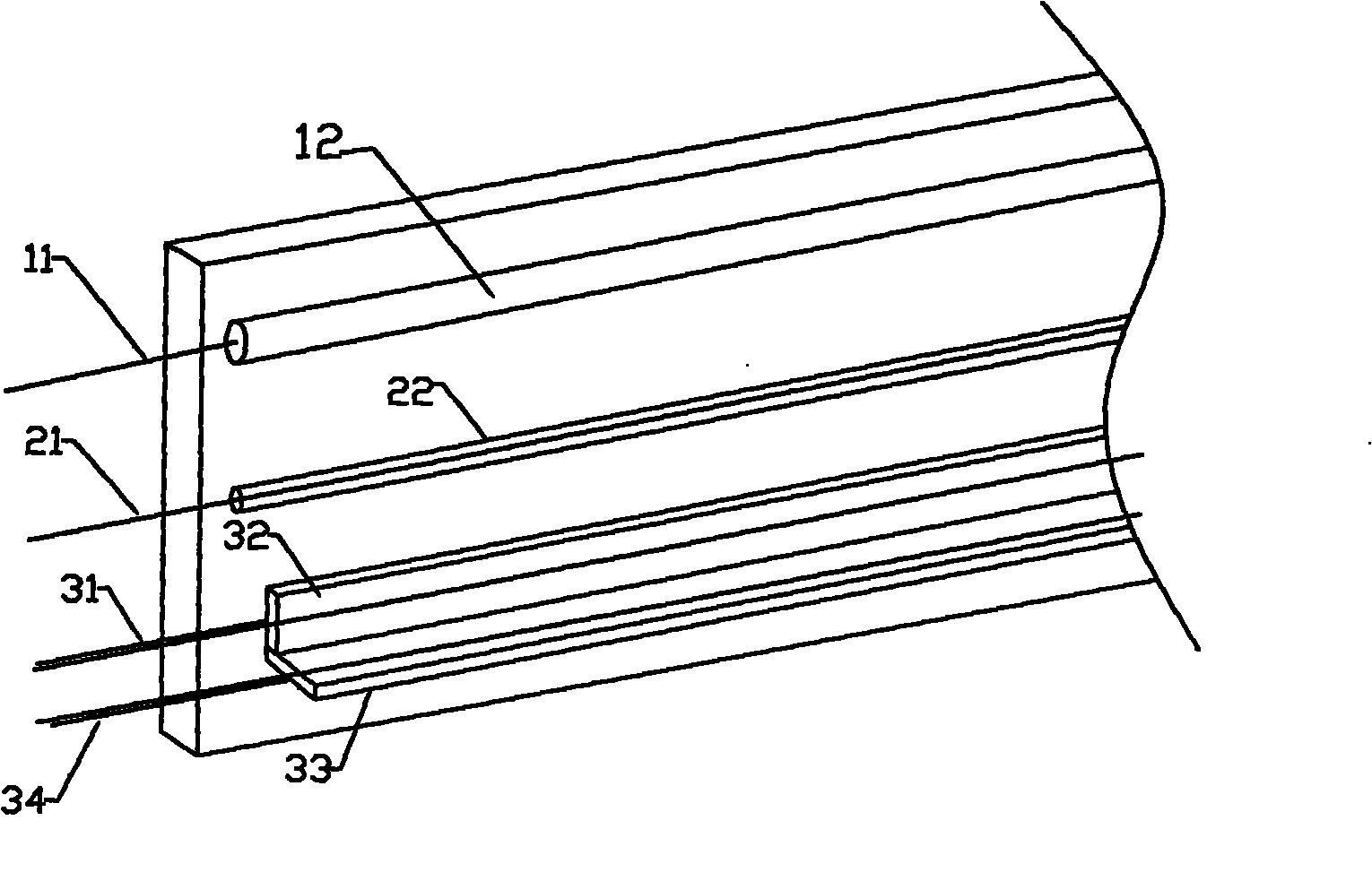

[0033] Such as Figure 1 to Figure 3 As shown, the composite optical fiber detection module of the present embodiment includes a base material 18 having a force-bearing surface, and the force-bearing surface of the base material 18 is provided with optical fiber structures I1, optical fiber structures II2 and Fiber Optic Structure III 3;

[0034] The optical fiber structure I 1 is a tubular structure, including an optical fiber I 11 and a steel pipe 12. The part of the optical fiber I 11 located on the force-bearing surface is protected by being sleeved into the steel pipe 12. The optical fiber I 11 is provided with a bow-tie structure 40, such as figure 1As shown, the bowknot structure 40 is formed behind the optical fiber 1 after passing through the baffle 41, and plays an elongated role when the optical fiber 1 is subjected to an external force. In practice, there can be more than one bowknot structure, respectively It is set at the position where both ends of the steel pi...

Embodiment 2

[0045] Such as Figure 7 As shown, the difference between the second embodiment and the first embodiment is that the strain mounting substrate II is not used, but the optical fiber III 31 is made of an optical fiber sensor engraved with a grating. The principle is to engrave a Bragg grating inside the optical fiber, Then use the fiber tuner to emit light of a certain frequency band, and reflect light of a certain wavelength after encountering the grating. In this way, when the external force changes, the distance of each grating will change, so the wavelength of the reflected light will also change. The data can realize the determination of the direction of external stress.

[0046] The composite optical fiber detection device using the composite optical fiber detection module of this embodiment includes an optical fiber tuner for emitting a light source and a spectrometer for recording light wave changes. The connection is simple and the technology is mature. Compared with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com