Correction method of a photomask

A photomask and light transmittance technology, applied in the field of photomask correction, can solve the problems of poor light transmittance, deterioration, insufficient light transmittance in the correction part, etc., and achieve the effect of preventing diffuse reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

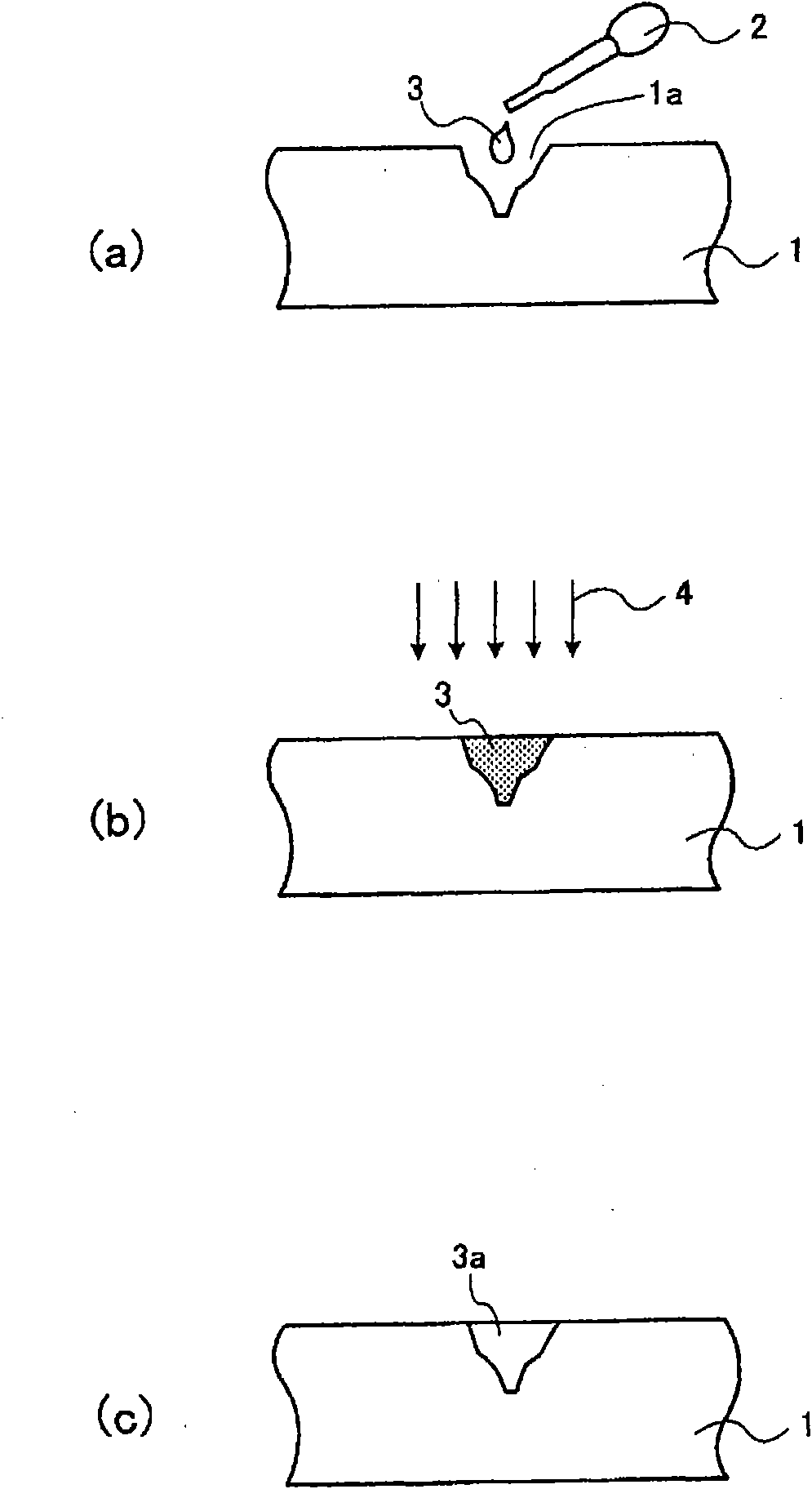

[0025] In this embodiment, a case where liquid glass is directly applied and hardened on the damage existing on the back surface of the photomask will be described.

[0026] The photomask of the present invention includes a photomask for LSI (Large Scale Integration), a photomask for FPD (Flat Panel Display), and a photomask for PWB (Printed Wiring Board: printed wiring board). Any kind of mask in photomask. Moreover, as a photomask in this invention, a binary mask (Binary Mask), a halftone mask (HalfTone Mask), an extreme ultraviolet mask (EUV Mask), etc. are mentioned. The photomask according to the present invention is particularly effective for a mask for FPD having a rectangular shape of 300 mm or more in one side and weighing 150 g or more. The above-mentioned photomask may be a multi-tone photomask including a transfer pattern having at least a light-shielding portion and a light-transmitting portion, and further having a semi-transmitting portion through which a part ...

no. 2 approach

[0042] In this second embodiment, a case will be described where liquid glass is applied to the damaged region after removing the damaged region on the back surface of the photomask and then cured.

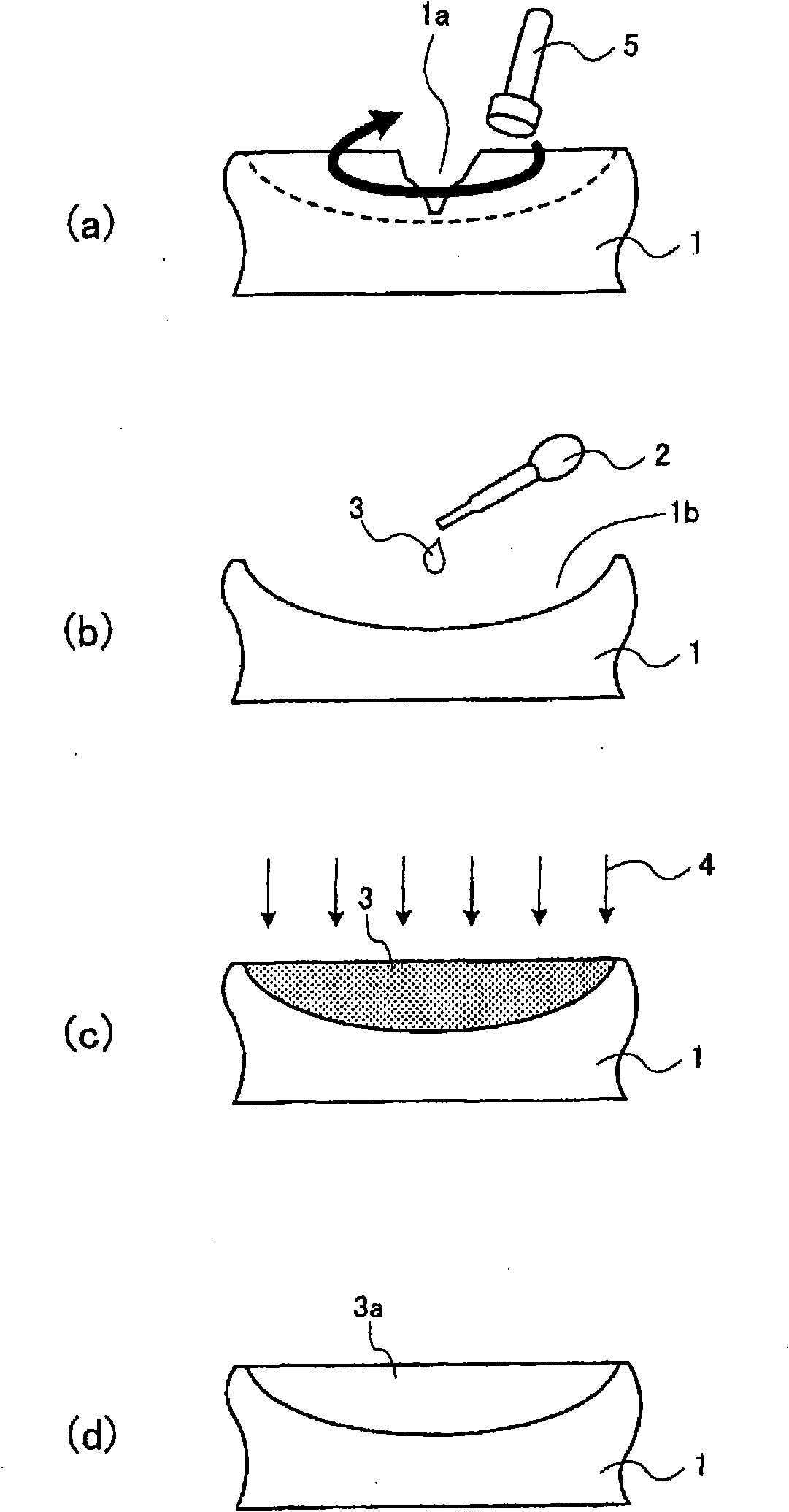

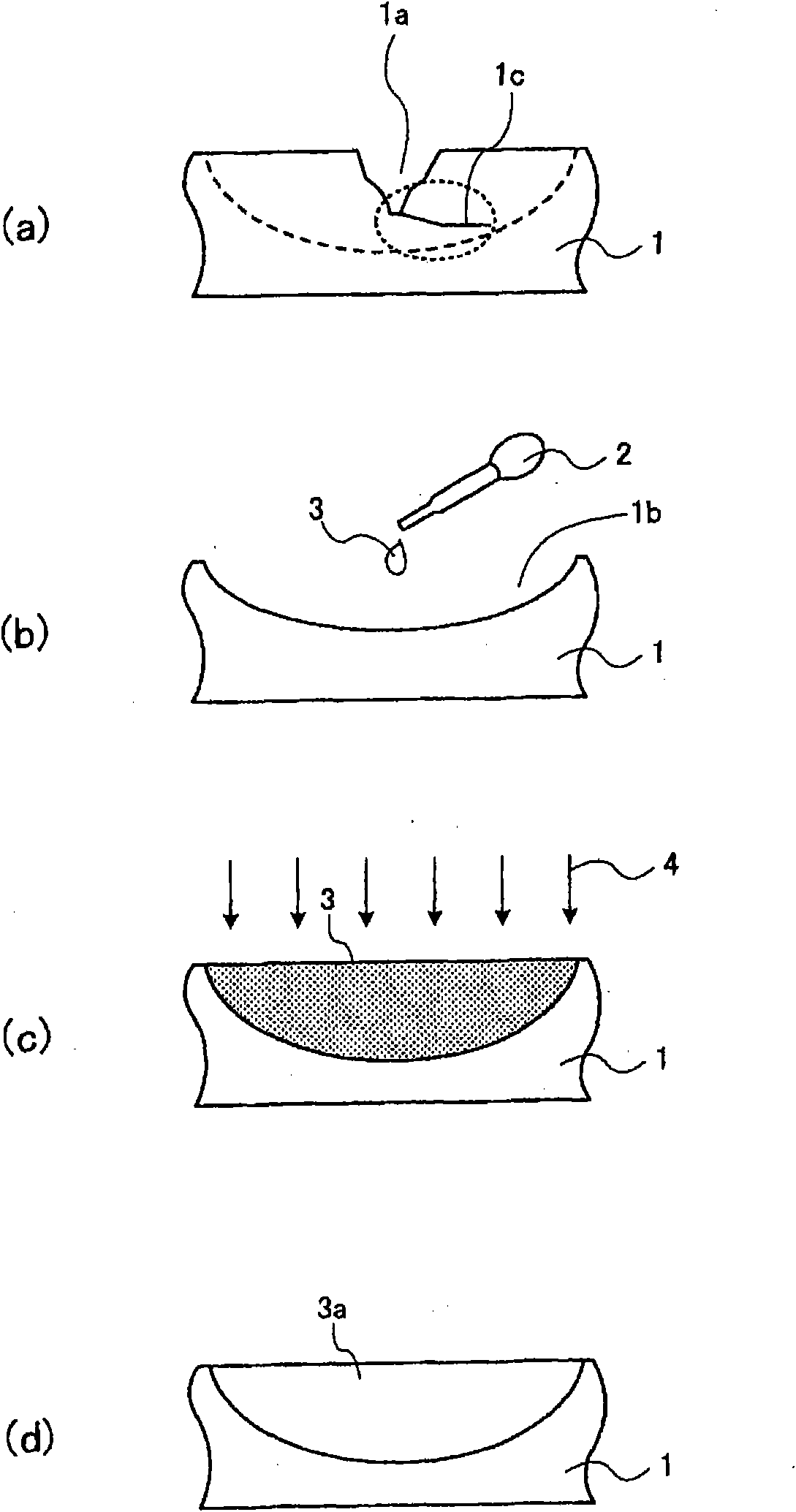

[0043] figure 2 (a)~(d) and image 3 (a)-(d) is a figure for demonstrating the correction method of the photomask which concerns on 2nd Embodiment of this invention. Here, the case where liquid glass is cured by ultraviolet rays will be described.

[0044] exist figure 2 In the shown mode, on the backside of the photomask 1 ( figure 2 The surface on the upper middle side) has damage 1a. Such as figure 2 As shown in (a), the router 5 is used to grind the region including the damage 1a (the region enclosed by the dotted line). Thus, if figure 2 As shown in (b), the recessed part 1b is formed in the back surface of the photomask 1. Next, the liquid glass 3 is applied to the concave portion 1b. Here, if figure 2 As shown in (b), the liquid glass 3 is applied by droppin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com