Maize straw ensilage process and ensilage pool for farmers

A technology of corn stalks and silage pools, which is applied in botany equipment and methods, animal feed raw material preservation methods, applications, etc., can solve the problems of large losses, achieve full utilization, strong practicability, and reduce environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further elaborated below in conjunction with the accompanying drawings.

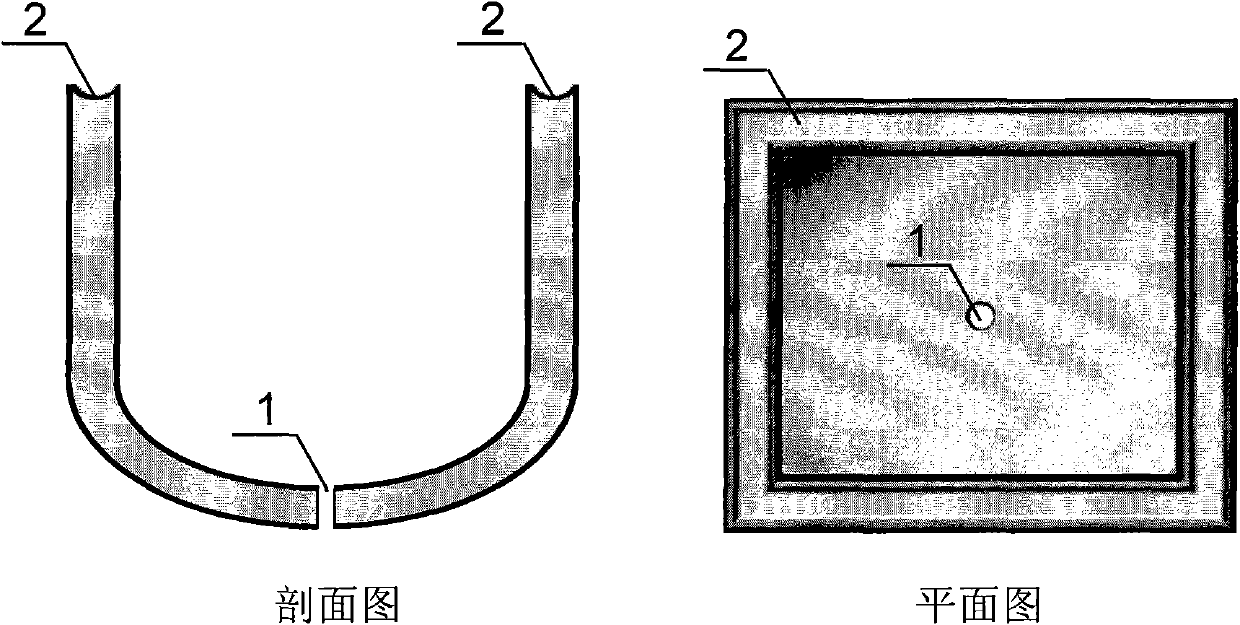

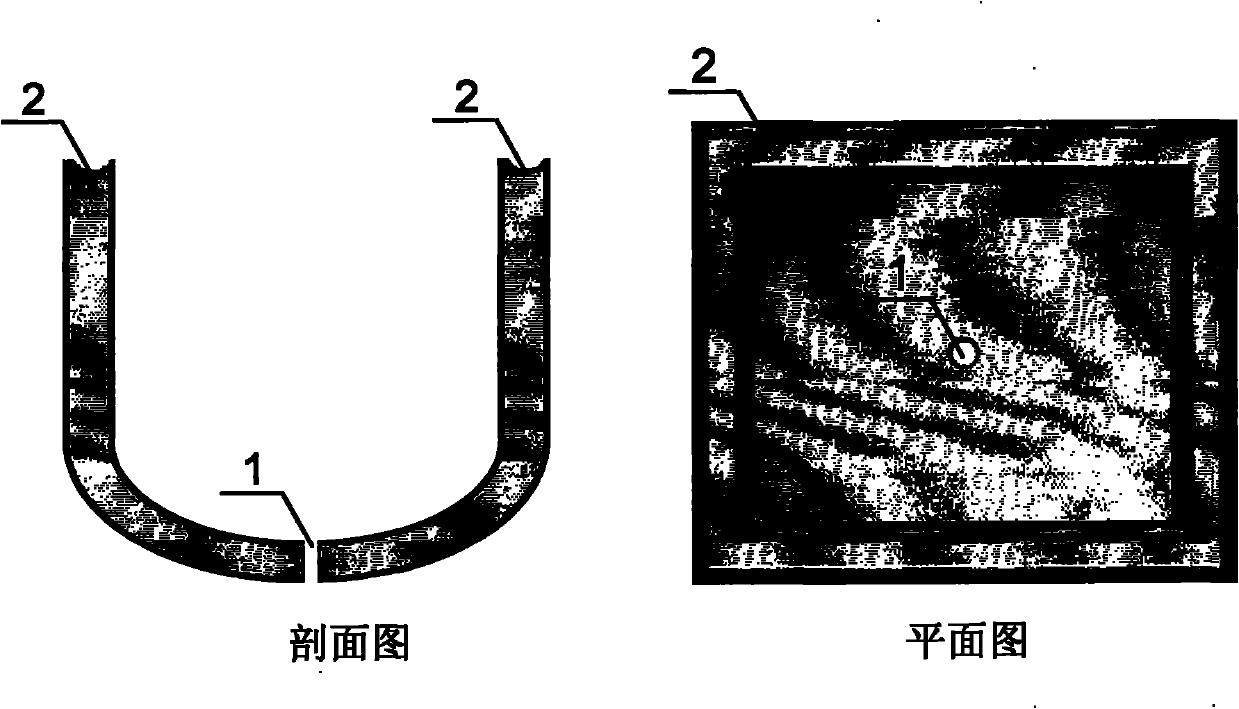

[0015] Such as figure 1 Shown is a corn stalk silage pond. The silage pond is a brick-concrete structure with an arc-shaped bottom and a drainage hole 1 with a diameter of 10 cm. Before filling the material, the drainage hole 1 is covered with bricks. To prevent the material from clogging the drain hole 1, water can flow into the drain hole 1 through the brick joint. The upper edge around the silage pool is a groove 2, and the groove 2 is 15-25cm wide and 5-10cm deep.

[0016] A method for ensilage of corn stalks, comprising the steps of:

[0017] After the corn is harvested, the fresh corn stalks are immediately harvested and cut into pieces of 10-20 mm. After the straw is chopped, according to the weight ratio of the straw, the urea is 4-6kg·t -1 , brown sugar is 2~3kg·t -1 , the salt is 0.5~1kg·t -1 , to weigh the added materials, add 20kg of water per ton of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com