Integrated control method and device of production operations of heating furnace and hot rolling of iron and steel enterprise

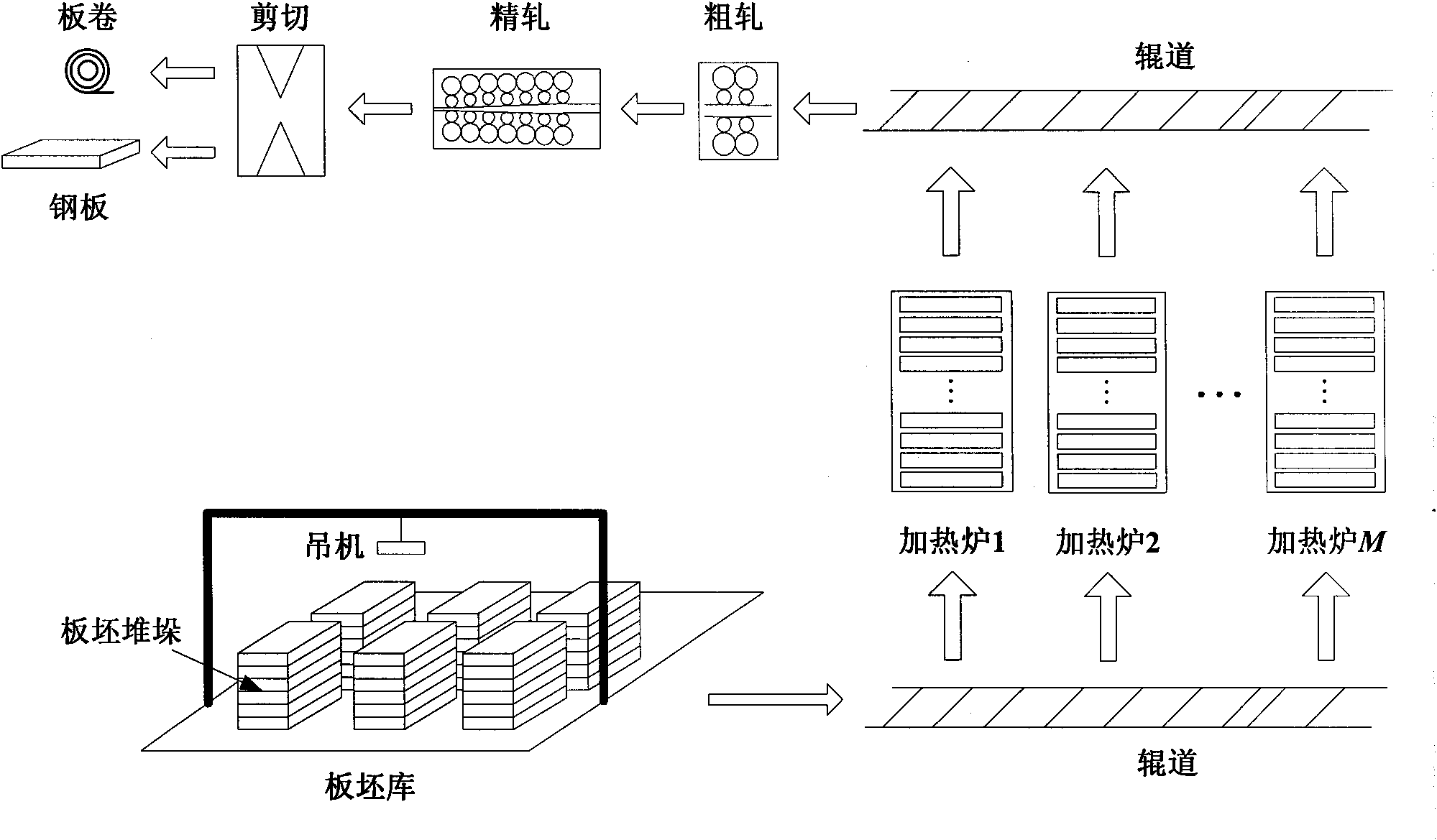

A technology of integrated control and heating furnace, applied in the fields of rolling mill control device, metal rolling, metal rolling, etc., can solve problems such as difficulty in overall planning, inability to achieve optimal control, low production capacity of heating furnaces, and low design production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

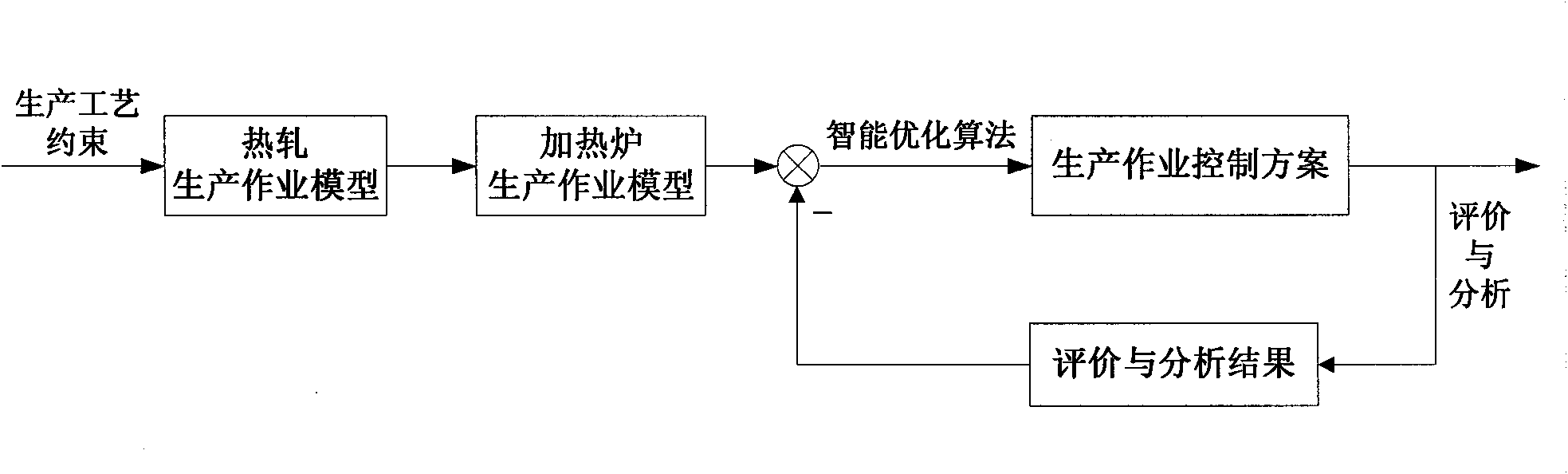

Method used

Image

Examples

Embodiment 1

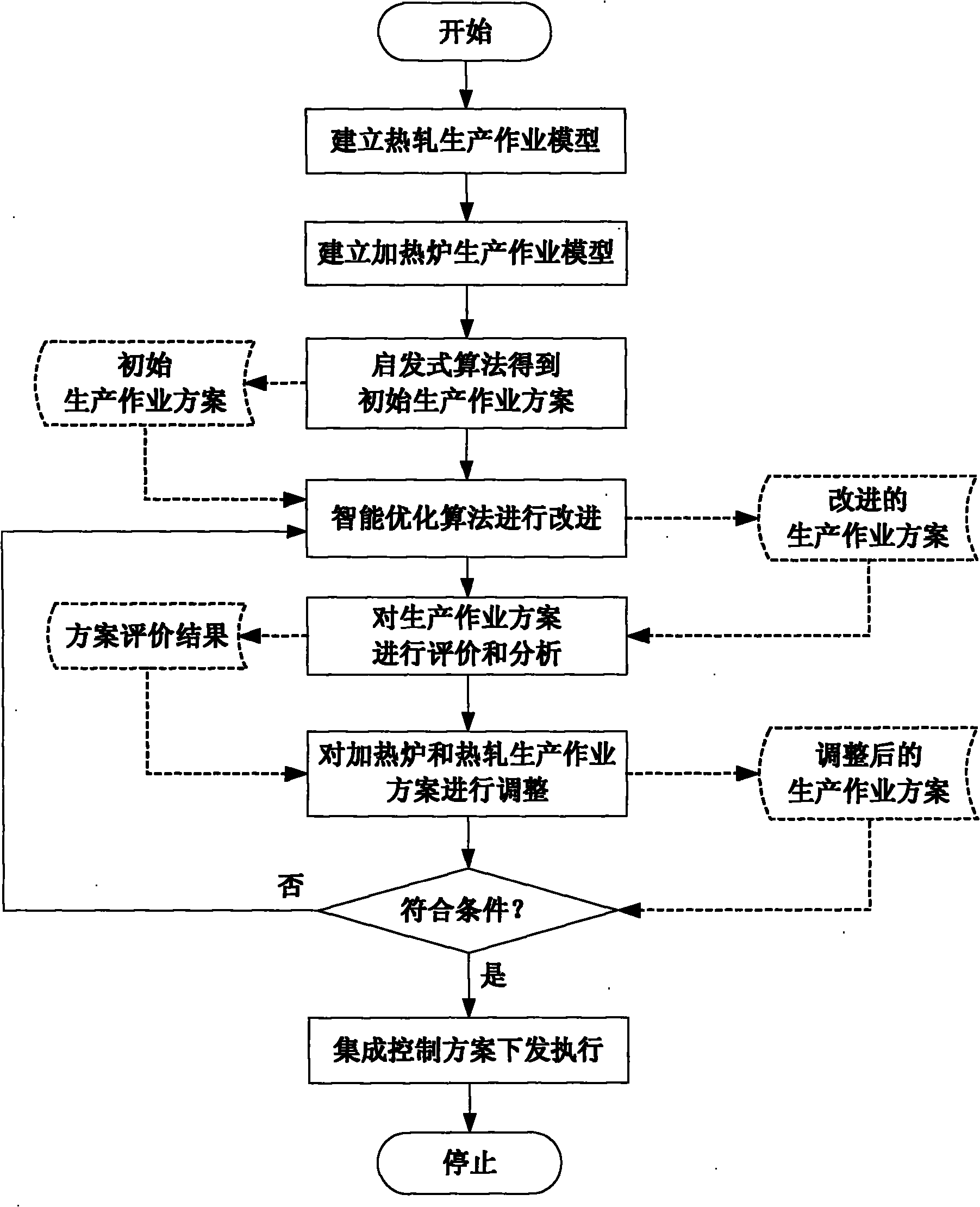

[0091] image 3 It is a flow chart of the integrated control method of heating furnace and hot rolling production operation of the present invention, and the specific steps of the control method are as follows:

[0092] Step 1: Determine the control objectives of the production and operation of the hot rolling mill, and establish the process constraints required for the normal operation of the mill itself;

[0093] In order to determine the control objectives and constraints, establish a hot rolling production operation model, and describe the production operation system of the hot rolling mill;

[0094] There is one hot rolling unit, and the current set of slabs to be rolled N={1, 2,...,n}, the established hot rolling production operation model is described as follows:

[0095] min imize Σ i = 1 n - 1 c ...

Embodiment 2

[0169] This embodiment is roughly the same as Embodiment 1, except that the intelligent optimization algorithm in Step 4 of the method for integrated control of heating furnace and hot rolling production operations adopts a simulated annealing algorithm, and uses the simulated annealing algorithm to optimize and improve the initial production operation integration scheme.

[0170] Based on the initial heating furnace and hot rolling production operation plan, use simulated annealing algorithm to optimize and improve it to further reduce hot rolling production cost, slab overburning time, hot rolling waiting time and total work of heating furnace time etc. Since the production operation plan of the heating furnace is determined based on the optimization of the hot rolling production operation plan, the optimization object of this algorithm is the hot rolling production operation plan, and its process is as follows Figure 8 As shown, the specific steps are:

[0171] Step 1. Ta...

Embodiment 3

[0178] This embodiment is roughly the same as Embodiment 1, except that the intelligent optimization algorithm in step 4 of the integrated control method for heating furnace and hot rolling production operations adopts a variable neighborhood search algorithm, and uses the variable neighborhood search algorithm to optimize the initial production operation integration scheme and improvements.

[0179] Based on the initial heating furnace and hot rolling production operation plan, the variable neighborhood search algorithm is used to optimize and improve it, so as to further reduce the production cost of hot rolling, the overburning time of slab, the waiting time of hot rolling and the total cost of heating furnace. Since the production operation plan of the heating furnace is determined based on the optimization of the hot rolling production operation plan, the optimization object of this algorithm is the hot rolling production operation plan, and its process is as follows Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com