Flame-retardant antibacterial finishing method for cellulose carpets

An antibacterial finishing and carpet technology, which is applied in fiber treatment, carpets, plant fibers, etc., can solve the problems of failing to meet the overall flame retardant requirements of small and medium-sized carpets and affecting the flame retardant performance of carpets, so as to reduce fire losses and ensure the safety of life and property , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

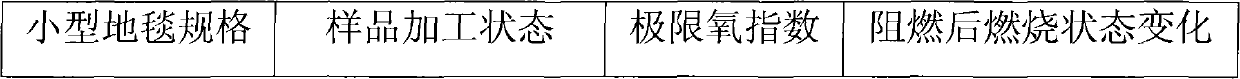

Embodiment 1

[0019] The flame retardant and antibacterial finishing agent compounded by organophosphorus compounds and active amino-based organic lipid compounds is used as the main component. The cotton fiber (pure cotton) small carpet is evenly laid on the processing table with the front facing up, and the compound is sprayed with a watering can or sprayer. The prepared finishing agent is evenly sprayed on the surface of the small carpet, and according to the thickness of the carpet, the extrusion height of the extrusion device is adjusted to squeeze the surface, and then it is dried according to the degree of wetting of the finishing agent absorbed by the carpet. The drying temperature is 100-120°C, the drying time is 3 minutes, and the moisture content of the dried product is 5%. Afterwards, the finishing agent is fully combined with the cellulose fiber by high-temperature baking, the baking temperature is 100° C., and the baking time is 3 minutes. Finally, the textiles are simply comb...

Embodiment 2

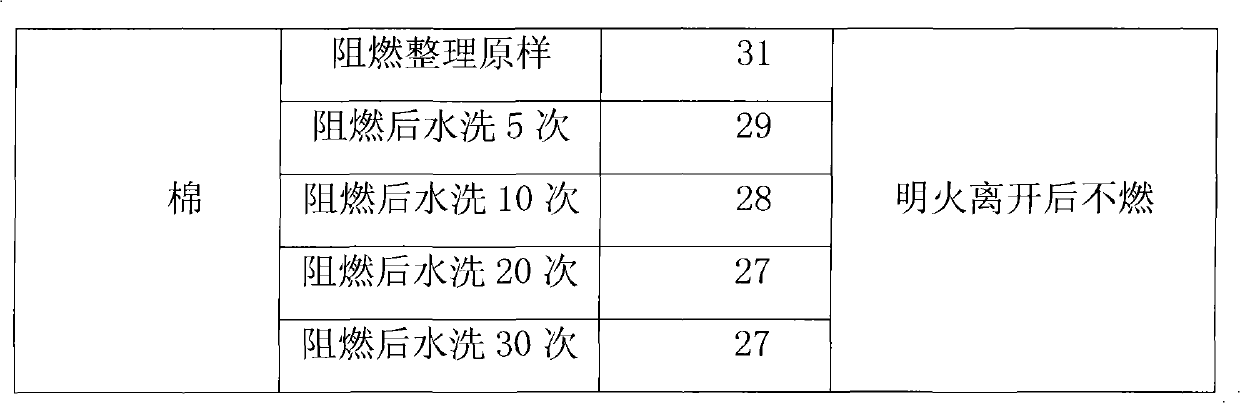

[0029] The flame retardant and antibacterial finishing agent compounded by organophosphorus compounds and active amine-based organic lipid compounds is used as the main component. Lay the viscose fiber small carpet face up evenly on the processing table, and use the watering can or sprayer to spray the compounded finishing agent. Spray evenly on the surface of the small carpet, adjust the extrusion height of the extrusion device to squeeze the surface according to the thickness of the carpet, and then dry it according to the degree of wetting of the carpet to absorb the finishing agent. The drying temperature is 120°C, the drying time is 10 minutes, and the moisture content of the dried product is 10%. Afterwards, the finishing agent is fully combined with the cellulose fiber by high-temperature baking, the baking temperature is 120° C., and the baking time is 10 minutes. Finally, the textiles are simply combed with special tools, so that the tufts on the front of the product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com