Novel light aggregate concrete building block and using method thereof

A lightweight aggregate concrete and concrete technology, applied in building materials, building components, walls, etc., can solve problems such as unachievable compressive strength, and achieve the effect of ensuring thermal performance and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

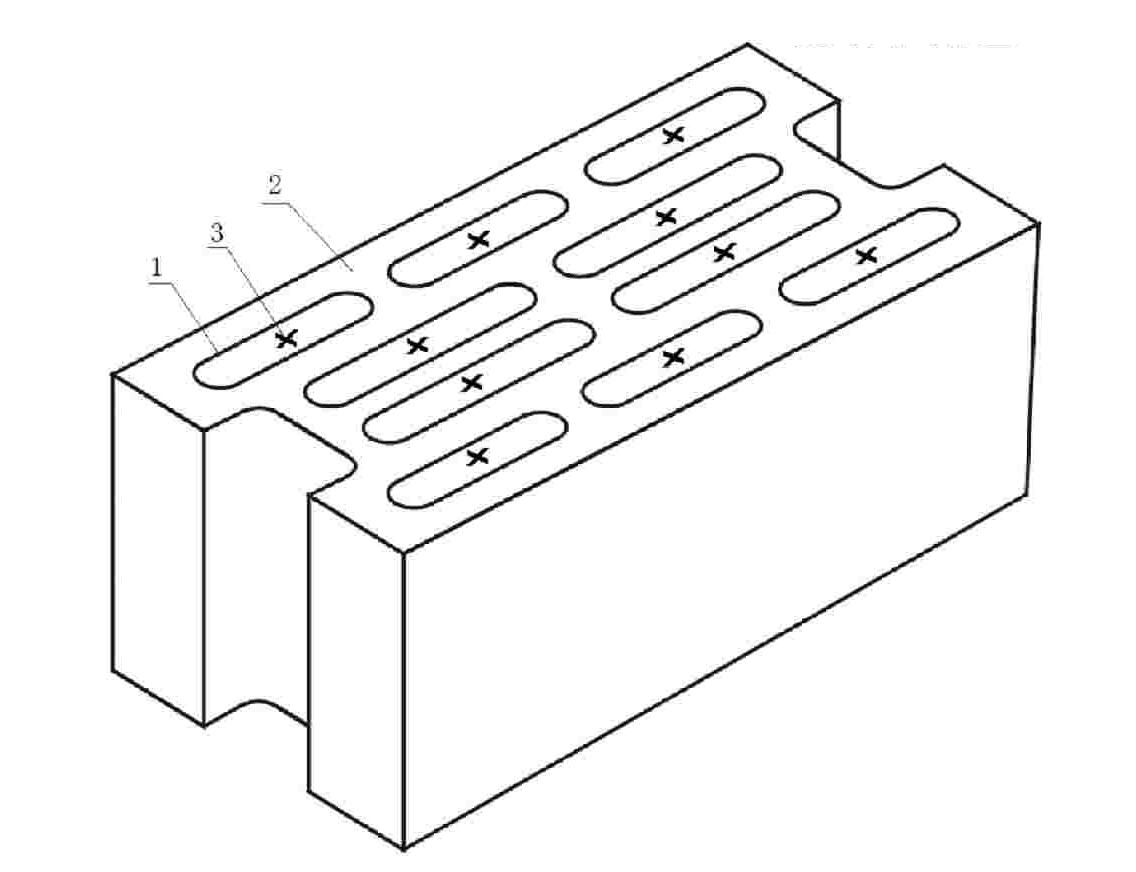

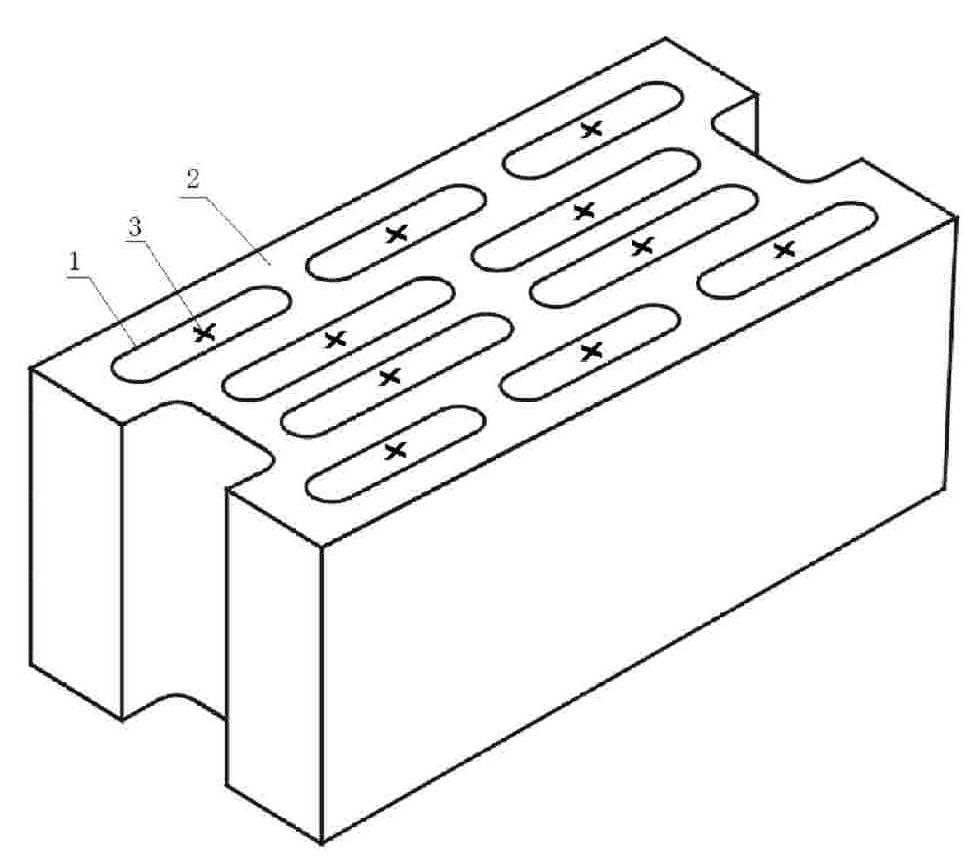

[0021] refer to figure 1 , The new light aggregate concrete block of the present invention includes a small hollow block 2 of light aggregate concrete with a cavity 1, and the feature is that a thermal insulation board 3 is inserted in the cavity. The volume ratio of each component of the above concrete formula is as follows: cement: fine aggregate: coarse aggregate: water = 5-15%: 20-50%: 20-50%: 5-15%.

[0022] In order to facilitate waste utilization and reduce production costs, the fine aggregate can be one or more of materials such as sand and bottom ash; the coarse aggregate can be stone, coal gangue, ceramsite, etc. One or several raw materials in the material.

[0023] In order to prolong the heat flow transmission line and enhance the heat preservation effect, the cavity of the hollow block has multiple rows of holes (usually elongated square holes), and two adjacent rows of holes are arranged in a staggered manner.

[0024] The implementation steps of the present i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com