Controlled blasting technique for small-clear-distance tunnel construction

A technology for controlling blasting and tunnel construction. It is applied in blasting and other directions. It can solve the problems of affecting the stability of surrounding rock, the safety of adjacent tunnels, the lack of construction personnel for construction, and the poor flexibility of construction plans, so as to improve the utilization rate of blast holes and ensure the construction progress. , the effect of protecting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

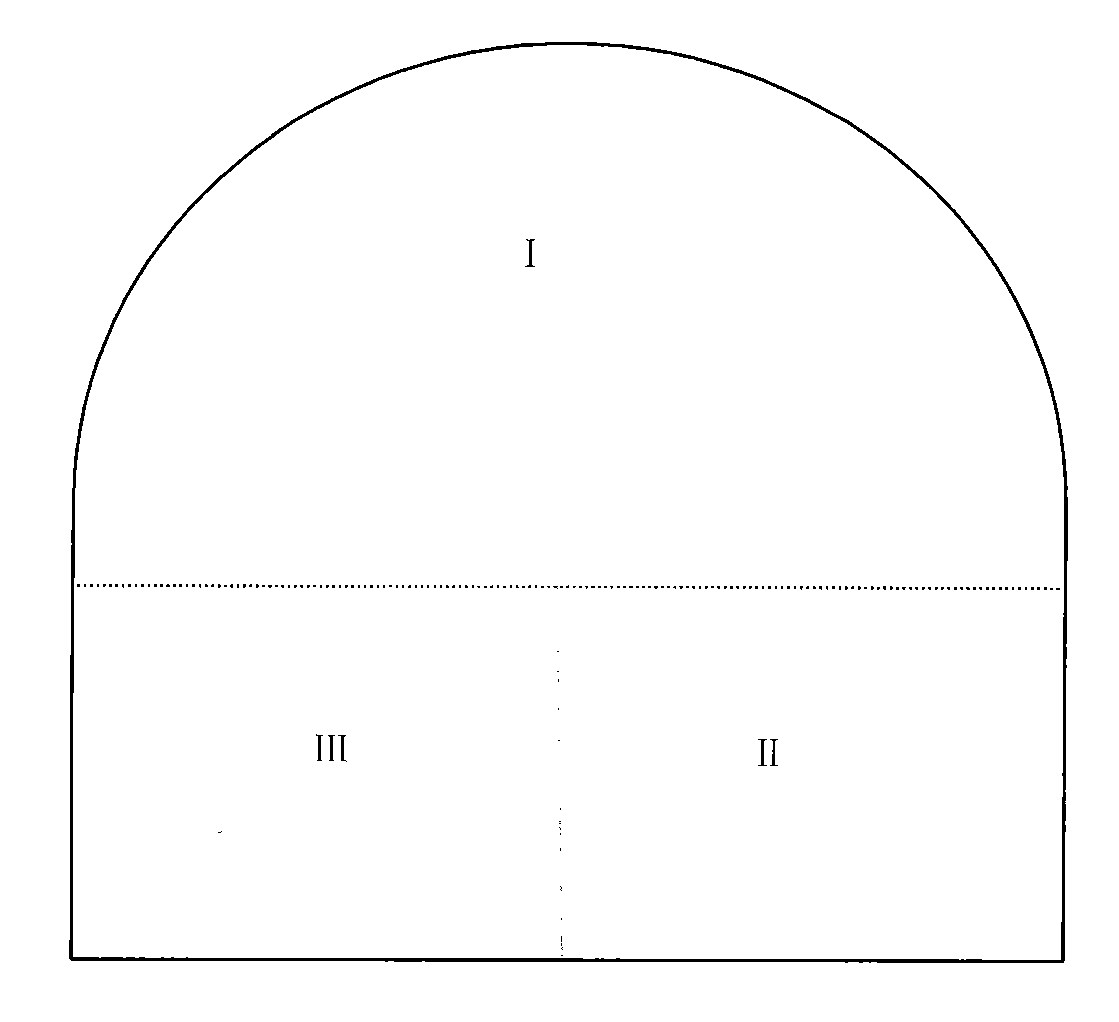

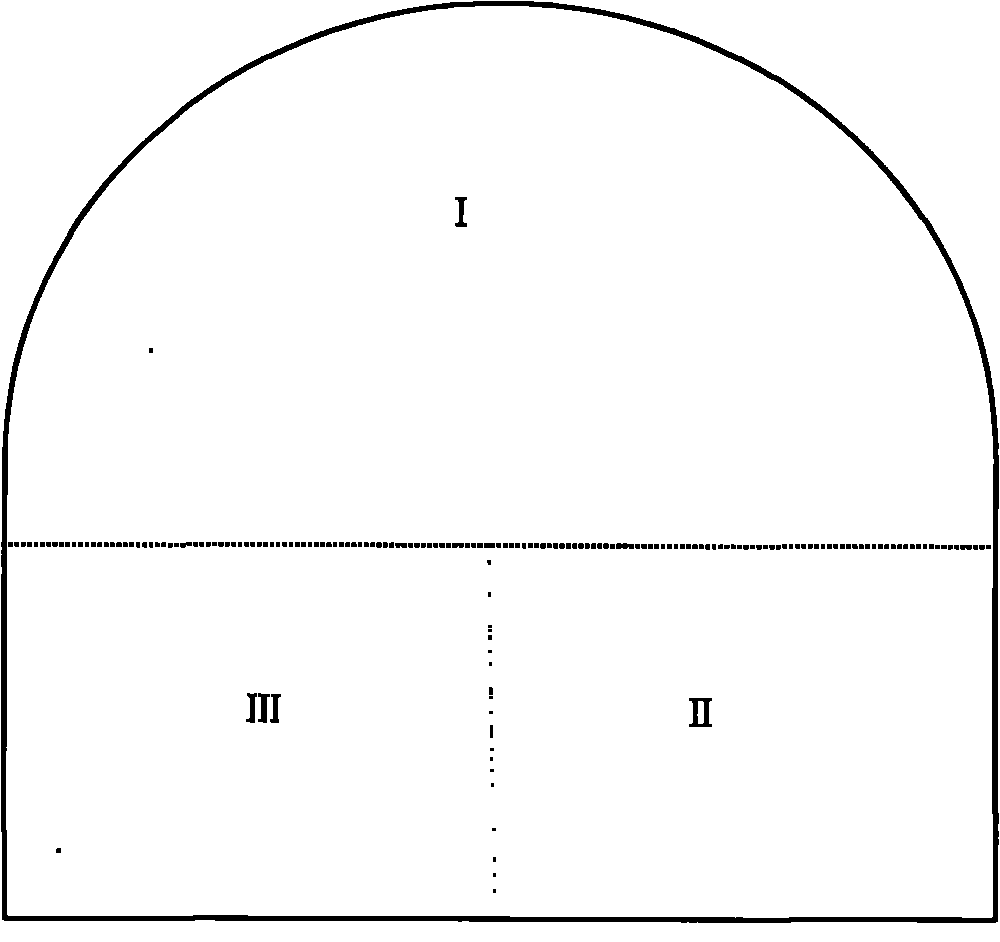

[0020] A controlled blasting technology for tunnel construction with small clear distance. The shortest distance between the two centers of the construction tunnel and the existing tunnel is 8-15m. The controlled blasting technology adopted in this embodiment is as follows: first step, according to the safety requirements of the adjacent tunnel, determine the safety standard of blasting vibration as 3-5 cm / s; Differential control blasting, as shown in Fig. 1, first excavates the first step, i.e. the upper step I, with a length of 5-10 m. The excavation adopts shallow-eye differential control blasting, and then successively excavates the second lower step II and the second step II. Excavation is carried out on the third step III, and the excavation length is 5-10m. The excavation also adopts shallow-eye differential control blasting; the third step is to repeat the second step until the entire construction of the tunnel is completed.

[0021] The control blasting parameters ar...

Embodiment 2

[0031] A controlled blasting technology for tunnel construction with small clear distance. The shortest distance between the construction tunnel and the two centers of the existing tunnel is 15-25m.

[0032] The control blasting parameters are:

[0033] The maximum single-stage drug dose is 5-6kg;

[0034] The blasting cycle footage is 0.9~1m;

[0035] The hole spacing E is (10-15)D.

[0036] All the other are with embodiment 1.

Embodiment 3

[0038] A controlled blasting technology for tunnel construction with small clear distance. The shortest distance between the construction tunnel and the two centers of the existing tunnel is 25-35m.

[0039] The control blasting parameters are:

[0040] The maximum single-stage drug dose is 5.5-7kg;

[0041] The blasting cycle footage is 1.0-1.2m;

[0042] The hole spacing E is (15-20)D.

[0043] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density ρ | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com