Super-resolution dual-axis differential confocal measurement method and device for division focal spot detection

A two-axis differential confocal and super-resolution technology, which is applied to measuring devices, optical devices, instruments, etc., can solve the problems of insufficient axial and lateral resolution, suppression of unfavorable light source intensity fluctuations, etc., and improve lateral resolution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

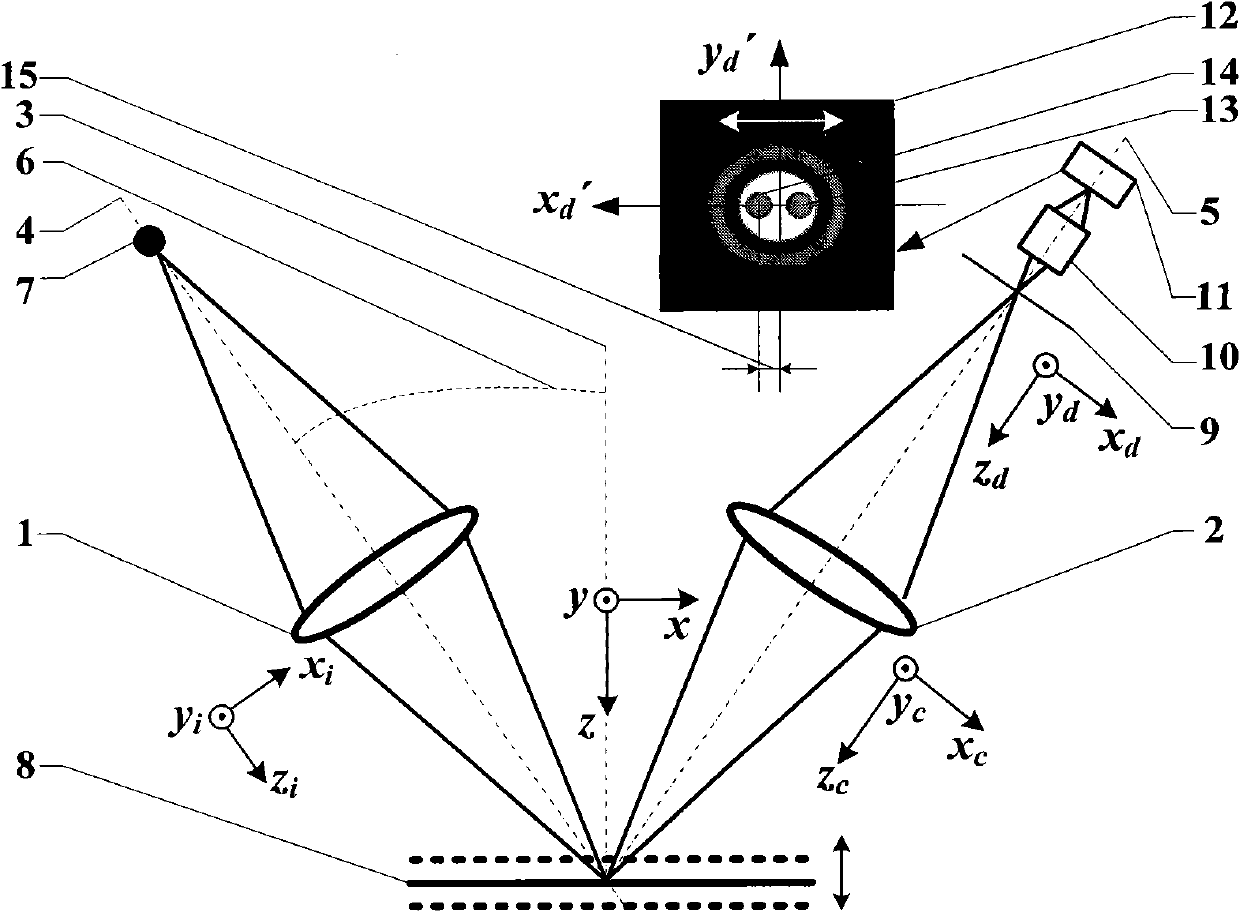

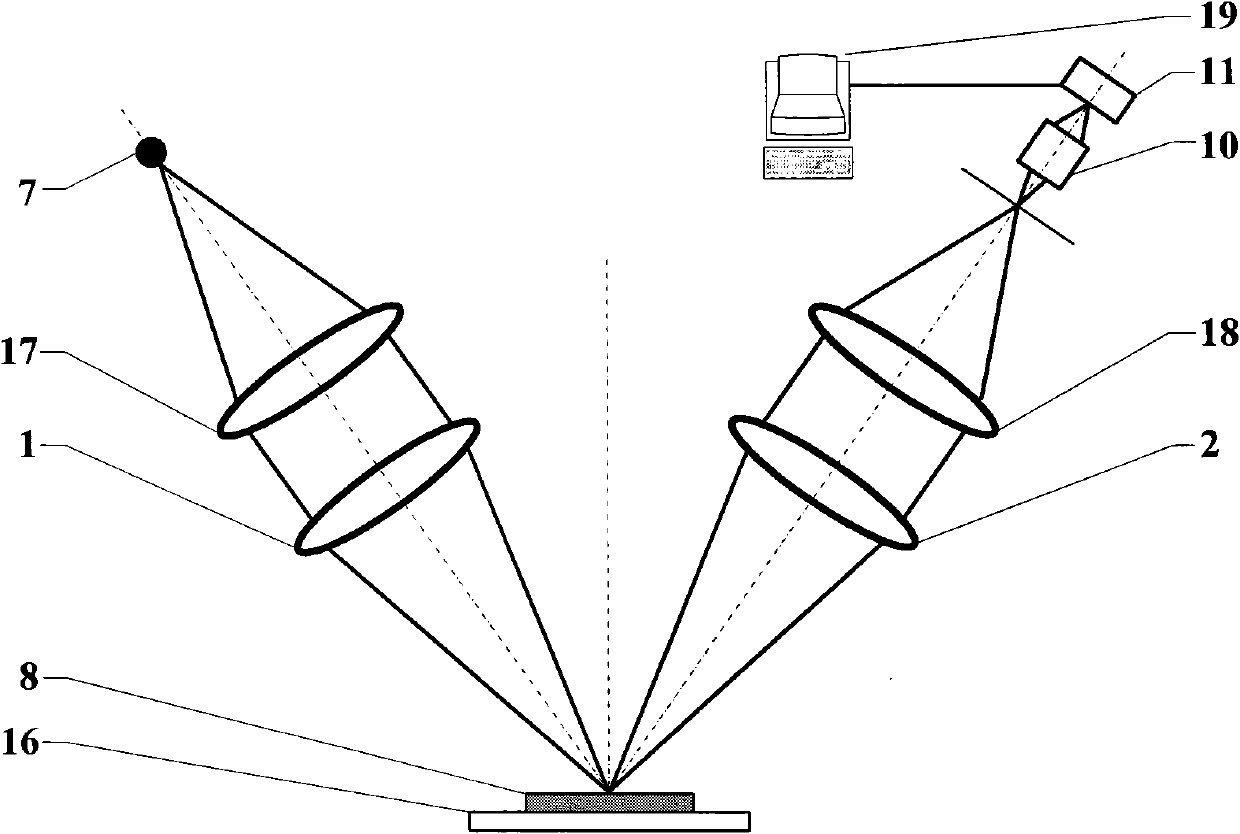

[0053] Such as image 3 As shown, the super-resolution dual-axis differential confocal measurement method for segmented focal spot detection, the measurement steps are:

[0054] First turn on the light source 7 (wavelength λ), and the outgoing light passes through the collimating beam expander 17 and expands the beam to be parallel light. Focusing on the surface of the measured sample 8 placed on the micro-displacement worktable 16, it is reflected into the collection lens 2, and the light beam collected by the collection lens 2 is converged by the measurement lens 18, and the converged light spot is enlarged by the microscope objective lens 10 and imaged on the CCD on detector 23.

[0055] The computer acquires the focal spot image 12 from the CCD detector 23, and when the sample 8 to be measured is located on the focal plane of the system, the computer calculates the center of the focal spot image 12 at this time, and uses the center as the coordinate origin to establish th...

Embodiment 2

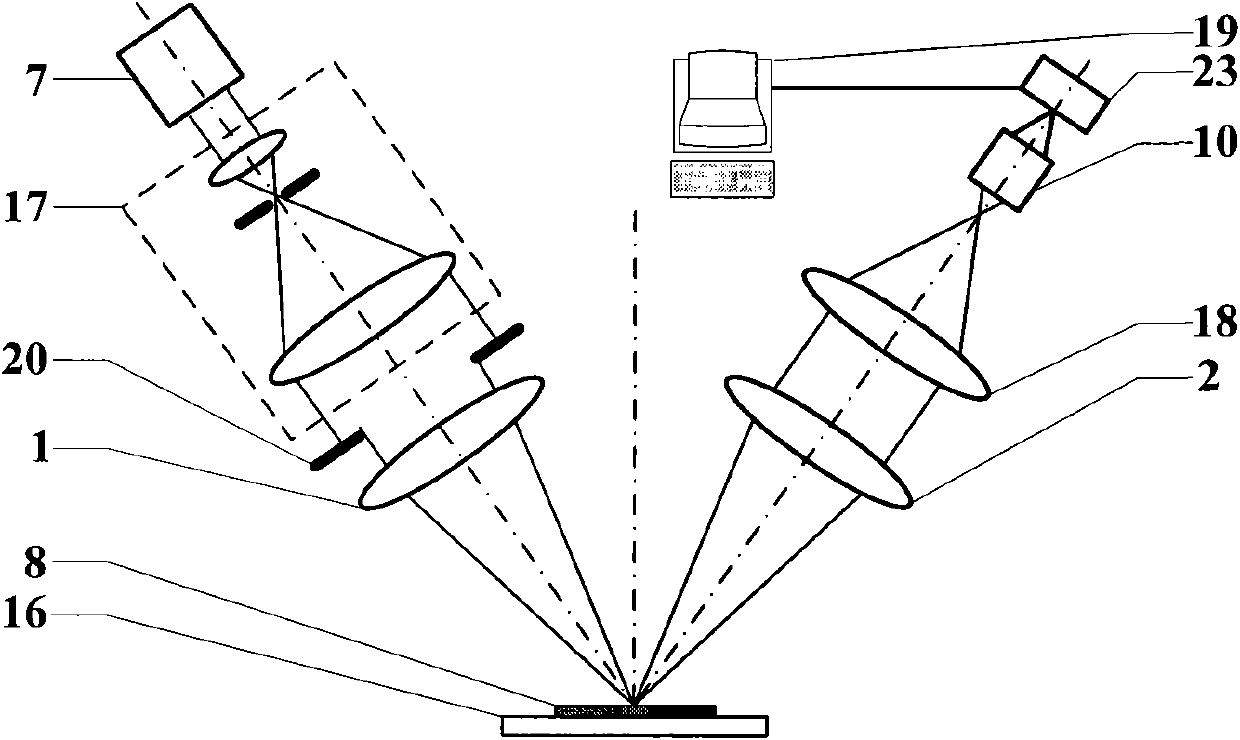

[0076] Such as Figure 6 As shown, the embodiment 1 image 3 A pupil filter 21 at the illumination end is added between the collimator beam expander 17 and the illumination lens 1 to filter and shape the illumination beam, so as to improve the lateral resolution of the system. All the other measuring methods and devices are the same as in Example 1.

Embodiment 3

[0078] Such as Figure 7 As shown, the embodiment 1 image 3 In the method, a pupil filter 22 at the collection end is added between the collection lens 2 and the measurement lens 18 to filter and shape the collection beam, so as to improve the lateral resolution of the system. All the other measuring methods and devices are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com