Phase-shifting full-bridge convertor real-time fault diagnosis method and system

A phase-shifting full-bridge, real-time fault technology, applied to instruments, measuring electrical variables, measuring devices, etc., can solve problems such as long program processing time, difficult application, and inability to accurately locate faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

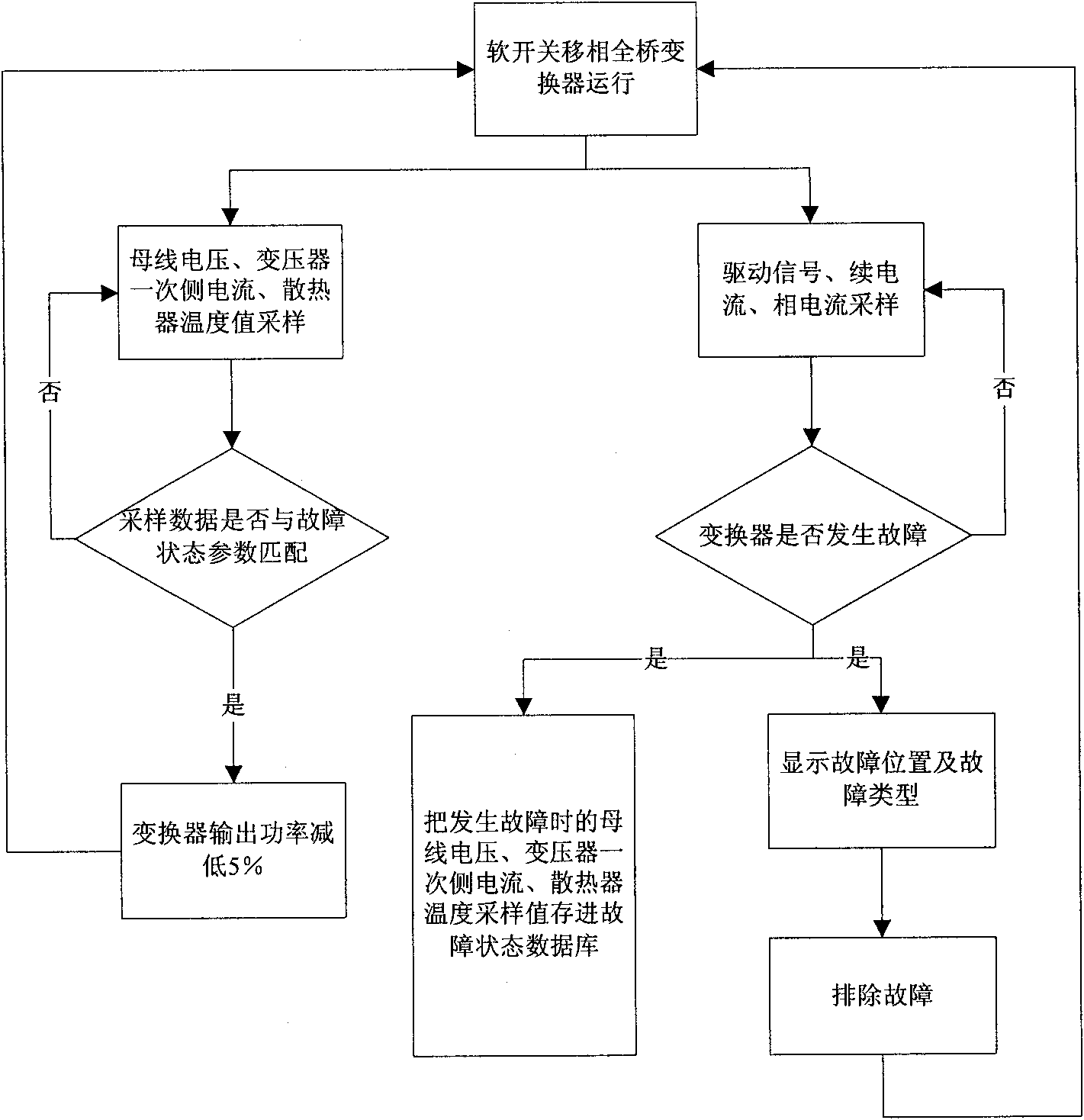

[0030] The specific implementation manners of the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

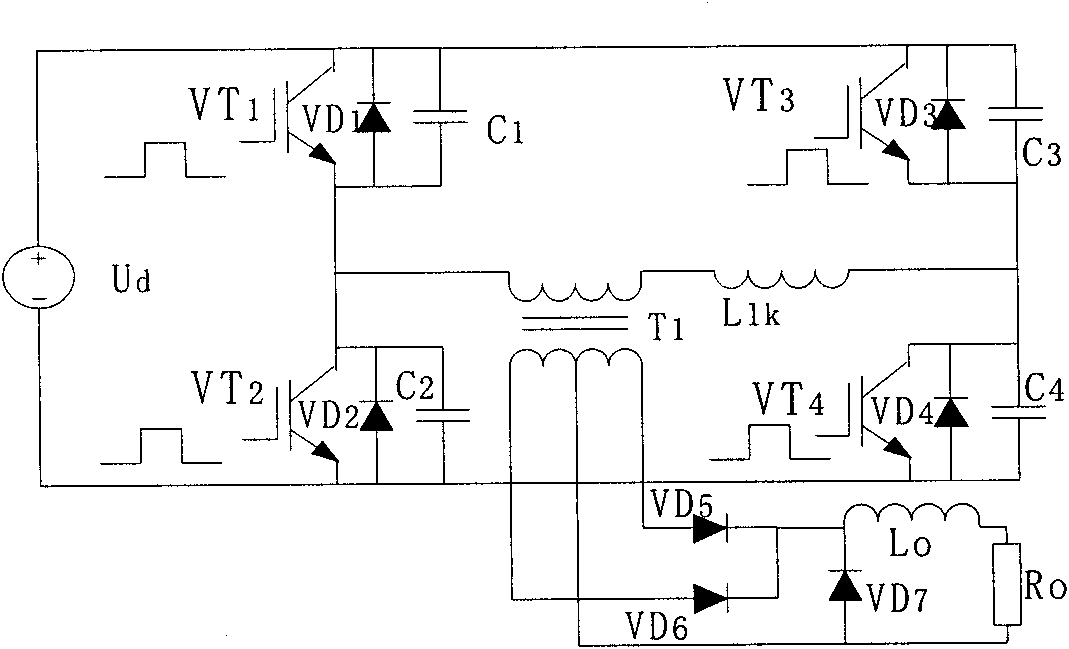

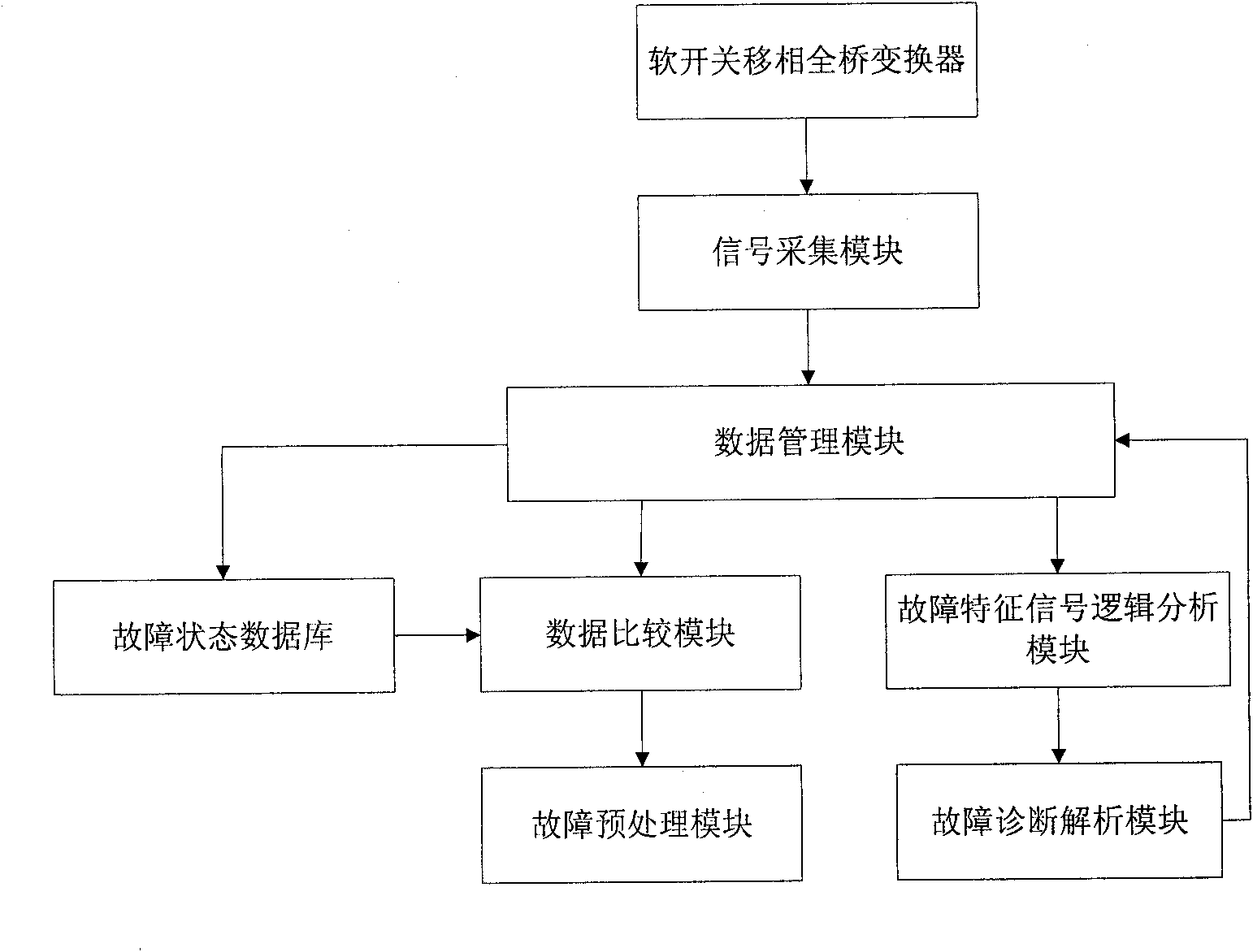

[0031] A real-time fault diagnosis method for a phase-shifted full-bridge converter proposed by the present invention. Current sensors are placed on the two lower bridge arms of the phase-shifted full-bridge converter. The sensor of the lower bridge arm obtains the freewheeling current signal of the power tube anti-parallel diode; in the negative half cycle of the switching cycle, the sensor of the lagging lower bridge arm obtains the freewheeling current signal of the power tube anti-parallel diode; the drive signal of the power tube is combined with the above positive half cycle or The freewheeling current signal obtained by negative half-cycle sampling is used to determine the fault condition of the phase-shifted full-bridge converter according to the logical relationship between the freewheeling current signal o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com