Strong inhibition type anti-collapse foam liquid for drilling

A technology of strong suppression and foam fluid, applied in the field of foam fluid for drilling, can solve the problems of ineffective protection of the well wall and instability of the well wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

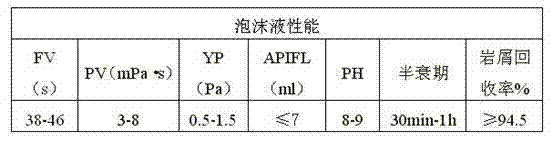

Image

Examples

Embodiment 1

[0011] A strong anti-collapse foam solution for well drilling is prepared by the following formula:

[0012] 0.1 kg of foam stabilizer is specifically: the molecular formula is [C 6 h 7 o 2 (OH) 2 CH 2 COONa] n Wherein the high-viscosity carboxymethyl cellulose of n=6 million is 0.05 kilogram and molecular formula is (C 35 h 49 o 29 ) n Wherein n=1.6 million xanthan gum XCD is 0.05 kg;

[0013] 0.4 kg of foaming agent is specifically: 0.15 kg of sodium lauryl sulfate K-12, 0.15 kg of fatty alcohol polyoxyethylene ether sodium sulfate AES, 0.05 kg of polyethylene glycol octylphenyl ether OP-10, Trade name is 0.05 kilograms of the tensio-active agent of blowing agent SW-1;

[0014] 2.6 kilograms of anti-slump agents are specifically: 0.3 kilograms of secondary organic cation forming agents whose trade name is anti-slump agent CSJ-1, 0.3 kilograms of mud shale inhibitors whose trade name is mud shale inhibitor cation I, chlorinated Potassium KCL is 2 kg;

[0015] 3 k...

Embodiment 2

[0019] A strong anti-collapse foam solution for well drilling is prepared by the following formula:

[0020] 0.09 kg of foam stabilizer is specifically: the molecular formula is [C 6 h 7 o 2 (OH) 2 CH 2 COONa] n Wherein the high viscosity carboxymethyl cellulose of n=5,000,000 is 0.045 kilogram and molecular formula is (C 35 h 49 o 29 ) n Wherein n=1.5 million xanthan gum is 0.045 kg;

[0021] 0.36 kg of foaming agent is specifically: 0.135 kg of sodium lauryl sulfate K-12, 0.135 kg of fatty alcohol polyoxyethylene ether sodium sulfate AES, 0.045 kg of polyethylene glycol octylphenyl ether OP-10, Trade name is 0.045 kilograms of the tensio-active agent of blowing agent SW-1;

[0022] 2.34 kg of anti-slump agent is specifically: 0.27 kg of secondary organic cation forming agent whose trade name is anti-slump agent CSJ-1, 0.27 kg of mud shale inhibitor whose trade name is shale inhibitor cation I, chlorinated Potassium KCL is 1.8 kg;

[0023] 2.7 kg of fluid loss r...

Embodiment 3

[0026] A strong anti-collapse foam solution for well drilling is prepared by the following formula:

[0027] 0.11 kg of foam stabilizer is specifically: the molecular formula is [C 6 h 7 o 2 (OH) 2 CH 2 COONa] n Wherein the high-viscosity carboxymethyl cellulose of n=7 million is 0.055 kilogram and molecular formula is (C 35 h 49 o 29 ) n Wherein n=2 million xanthan gum XCD is 0.055 kg;

[0028] 0.44 kg of foaming agent is specifically: 0.165 kg of sodium lauryl sulfate K-12, 0.165 kg of fatty alcohol polyoxyethylene ether sodium sulfate AES, 0.055 kg of polyethylene glycol octylphenyl ether OP-10, Trade name is 0.055 kilograms of the tensio-active agent of blowing agent SW-1;

[0029]2.86 kg of anti-slump agent is specifically: 0.33 kg of secondary organic cation forming agent whose trade name is anti-slump agent CSJ-1, 0.33 kg of mud shale inhibitor whose trade name is shale inhibitor cation I, chlorinated Potassium KCL is 2.2 kg;

[0030] 3.3 kilograms of fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com