Mobile-type laser processing device for on-line processing surface of steel rail

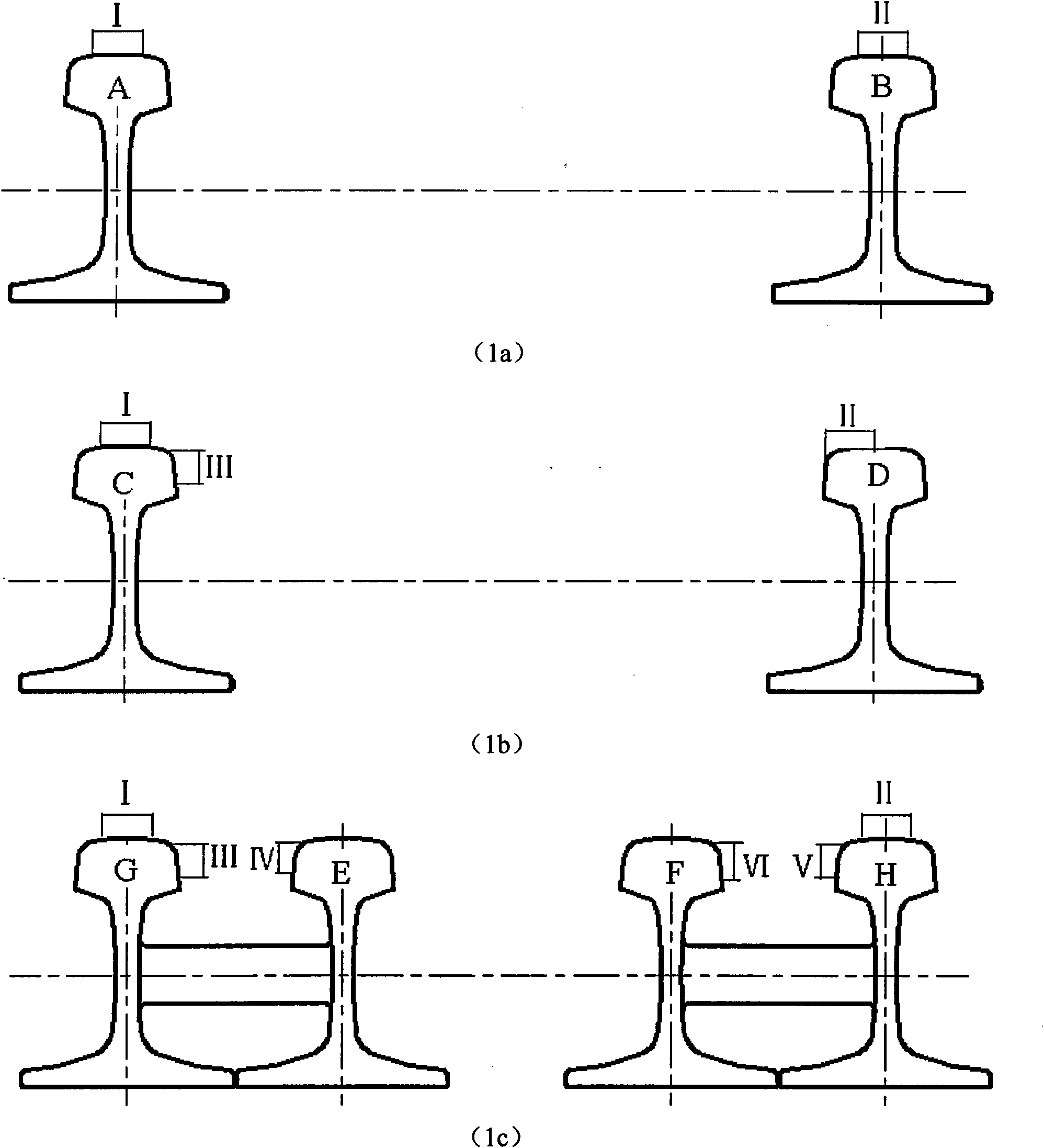

A technology of laser processing and laser processing head, which is applied in the direction of track, track laying, track maintenance, etc. It can solve the problems of low processing efficiency, long time consumption, and inability to produce martensite, etc., and achieve light weight, convenient operation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in more detail below by means of drawings and examples, but the following examples are only illustrative, and the protection scope of the present invention is not limited by these examples.

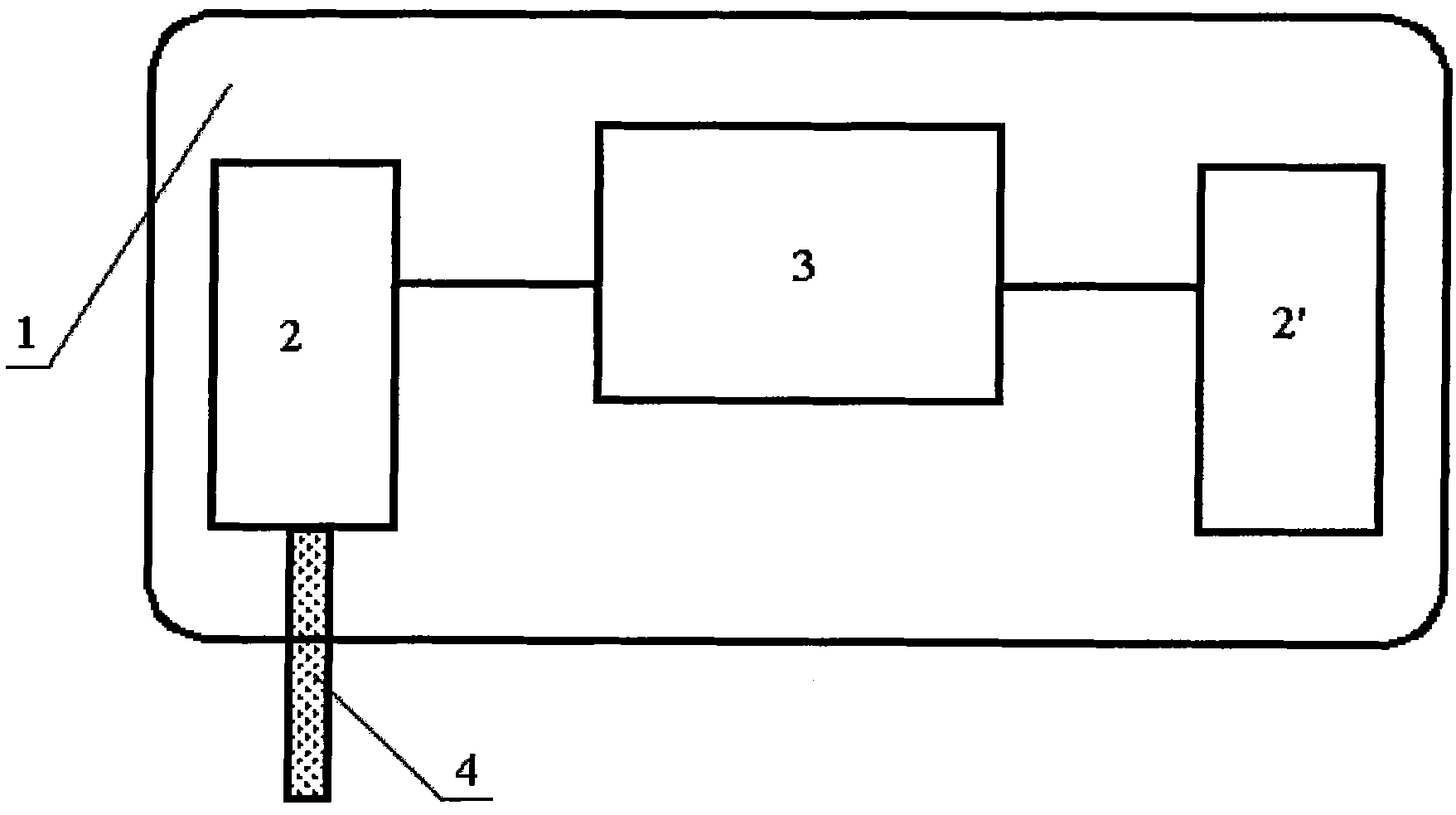

[0043] The structure of the mobile laser processing device provided by the present invention is as follows: figure 2 As shown, it includes a trolley 1, a light guide system 4, and the first and second motion processing mechanisms 2 and 2' installed on the trolley 1 and the control system 3

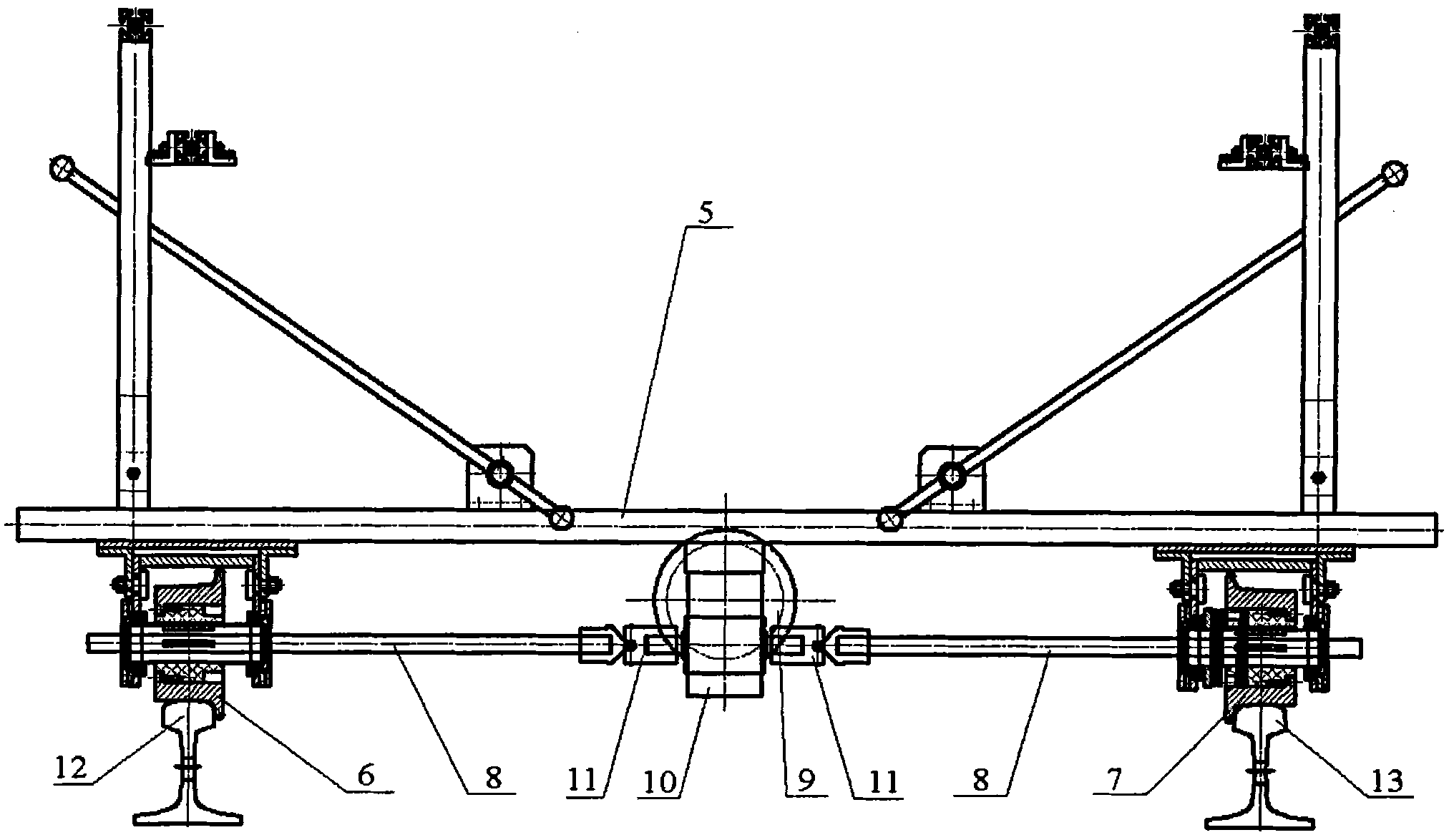

[0044] The trolley 1 can be a three-wheel, four-wheel, or six-wheel structure, taking the four-wheel structure as an example, such as image 3 , as shown in 4, the structure of car 1 is:

[0045] Two front wheels 14, and first and second rear axle drive wheels 6 and 7 are respectively installed on the vehicle body 5, and the gear reducer 10 is fixed on the bottom of the vehicle body 5, and the input shaft of the gear reducer 10 is driven by the gear and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com