Electromagnetic ultrasonic flaw detecting method for eliminating electromagnetic ultrasonic Lamb wave multi-mode influence

An electromagnetic ultrasonic and flaw detection technology, which is applied in the direction of using ultrasonic/sonic/infrasonic waves, using sound waves/ultrasonic/infrasonic waves to analyze solids, measuring devices, etc., can solve the problems of complex echo signals and undetectable problems, so as to improve detection performance, The effect of removing multimodal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

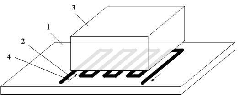

[0009] Embodiment 1: The electromagnetic ultrasonic flaw detection method for eliminating the multi-mode influence of electromagnetic ultrasonic Lamb waves described in this embodiment, its specific process is: first, according to the material properties and thickness of the test piece 1 in the electromagnetic ultrasonic transducer, Determine the spacing L of the meander coil 2 of the electromagnetic ultrasonic transducer and its fluctuation range is [L-ΔL, L+ΔL] and the excitation current frequency f and its bandwidth range [f-Δf, f through the meander coil 2 +Δf], causing the probe of the electromagnetic ultrasonic transducer to excite a single-mode electromagnetic ultrasonic Lamb wave in the test piece 1 or to excite multiple modes of electromagnetic ultrasonic Lamb waves with the same propagation velocity, and then start detection , the probe of an electromagnetic ultrasonic transducer is used to send a detection signal to the test piece 1, and the detection signal is recei...

specific Embodiment approach 2

[0011] Specific embodiment 2: This embodiment is a further description of specific embodiment 1. According to the material properties and thickness of the test piece 1 in the electromagnetic ultrasonic transducer described in the specific embodiment 1, the electromagnetic ultrasonic transducer is determined. The spacing L of the zigzag coil 2 and its fluctuation range are [L-ΔL, L+ΔL] and the excitation current frequency f and its bandwidth range [f-Δf, f+Δf] passed through the zigzag coil 2, so that the The method that the probe of the electromagnetic ultrasonic transducer excites the electromagnetic ultrasonic Lamb wave of a single mode in the test piece 1 is:

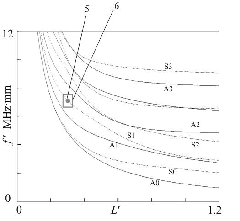

[0012] Step 1: Obtain the material properties of the test piece 1 in the electromagnetic ultrasonic transducer, the material properties include thickness, shear wave velocity and longitudinal wave velocity, according to the material properties and electromagnetic ultrasonic Lamb wave excitation equation

[0013] , ...

specific Embodiment approach 3

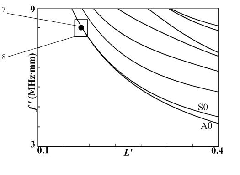

[0031] Specific embodiment three: This embodiment is a further description of specific embodiment one. According to the material properties and thickness of the test piece 1 in the electromagnetic ultrasonic transducer described in the specific embodiment one, the electromagnetic ultrasonic transducer is determined. The fluctuation range of the spacing L of the meandering coil 2 is [L-ΔL, L+ΔL] and the bandwidth range [f-Δf, f+Δf] of the excitation current frequency f in the meandering coil 2, so that the electromagnetic The method for the probe of the ultrasonic transducer to excite multiple modes of electromagnetic ultrasonic Lamb waves with the same propagation velocity in the test piece 1 is as follows:

[0032] Step A: Obtain the material properties of the test piece 1 in the electromagnetic ultrasonic transducer, the material properties include thickness, shear wave velocity and longitudinal wave velocity, according to the material properties, electromagnetic ultrasonic L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com