Biomass treatment apparatus

A biomass and equipment technology, applied in the field of biomass processing equipment, can solve the problems of uneconomical and expensive extruders, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

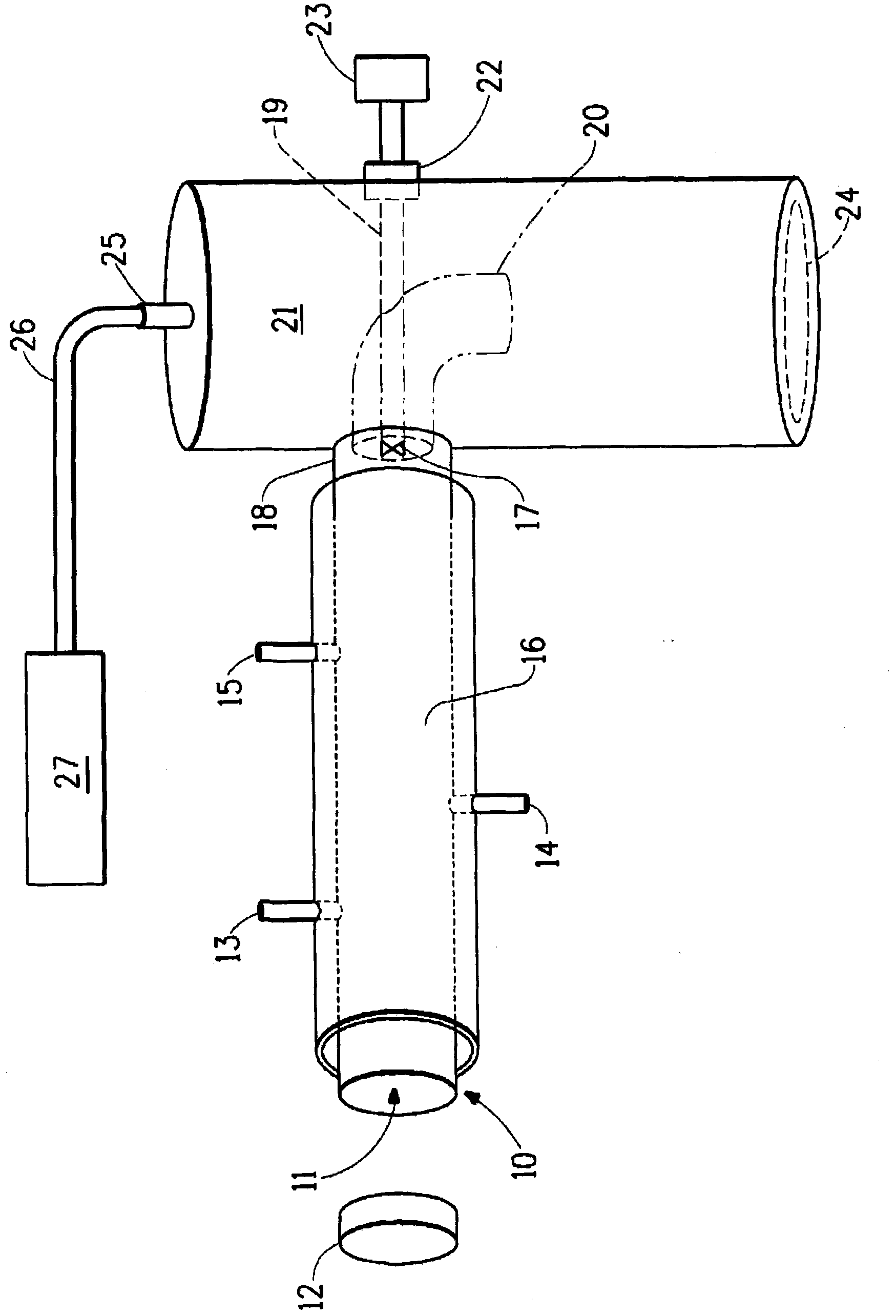

[0154] Corn cob pretreatment in a small barrel piston reactor

[0155] Whole cobs were processed with a jaw crusher (2.2 kW motor) with a jaw spacing of approximately 0.95 cm, followed by a crusher (1.5 kW motor, Franklin Miller Inc., Livingston, NJ), followed by a 1.9 cm machine equipped with a U.S. A Sweco sieve of standard mesh size is used to sieve the whole cob into smaller pieces. A small barrel-piston reactor (as described in General Methods) was charged with 115 g (dry weight basis) of crushed corn cobs, and the cobs were placed by hand at the end of the reactor with the piston removed. Put the plunger back in place to plug the end. The reaction vessel is evacuated to reduce the pressure to <10kPa (0.1bar), and the diluted ammonium hydroxide solution is injected into the reactor so that the ammonia concentration is 4g or 6g per 100g dry weight of biomass (as shown in Table 1). The dry weight concentration of the substance is 50g per 100g of the total biomass and am...

Embodiment 2

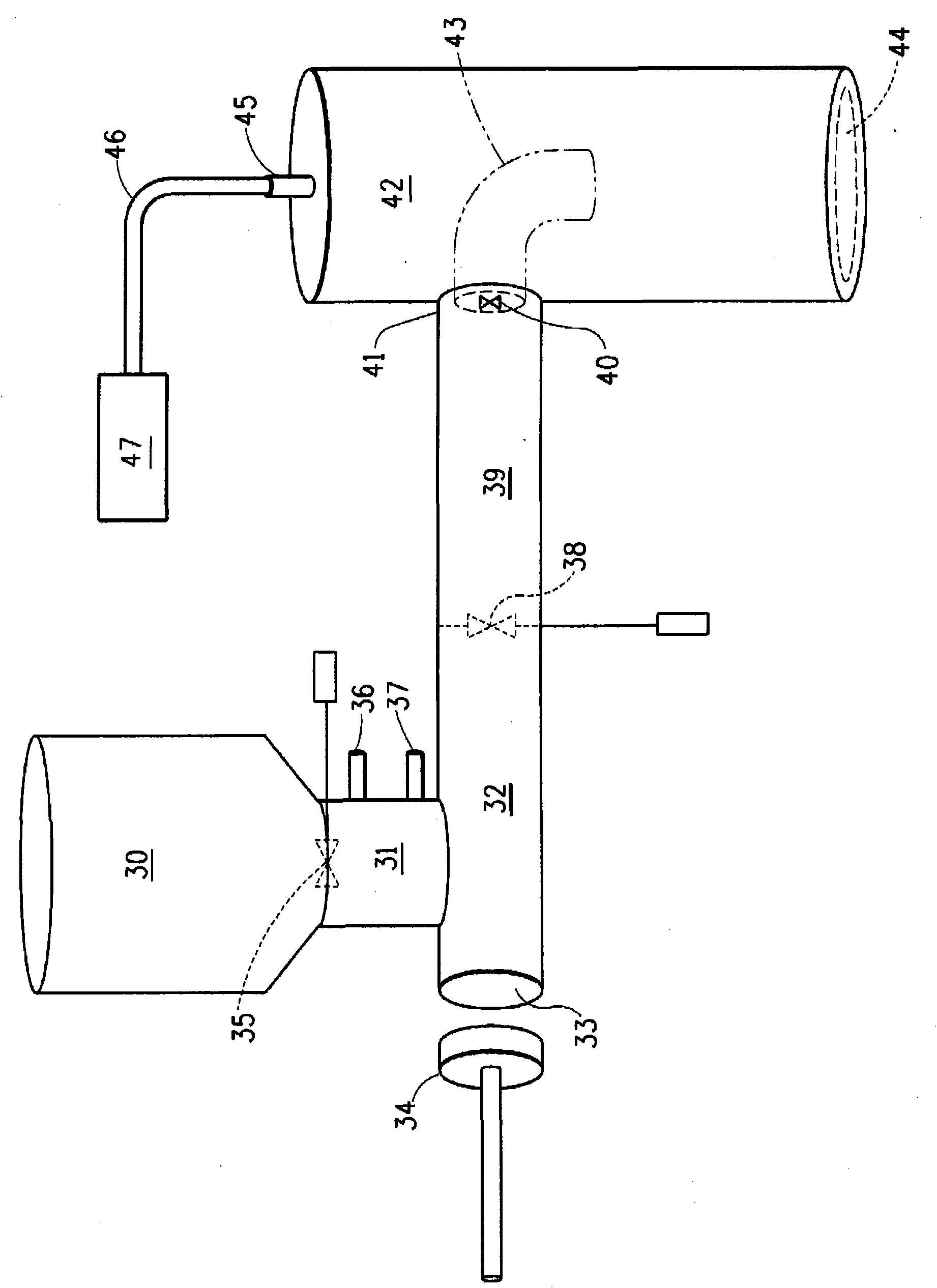

[0160] Pretreatment in a large barrel piston reactor at different times

[0161] The cylinder of a large tubular piston reactor (as described in the general procedure) was preheated to about 130°C by adding steam to the cylinder jacket. The flash receiver was preheated to about 60°C with a band heater. Cracked cobs were prepared as described in Example 1. These cobs (175 g on a dry weight basis) were loaded by hand into a large barrel reactor, which was placed at the end of the reactor with the plunger removed. Put the plunger back in place to plug the end. The reaction vessel and the flash receiver are evacuated to reduce the pressure to CP cellulase and 4.2 mg active protein / g cellulose hemicellulase consortium (Diversa) at 50°C, pH 5.5 for 72 hours, the enzyme consortium comprising xylanase, β-wood Glycosidase, arabinosidase, and beta-glucosidase. The yields given in Table 2 below are the releases given as a percentage of the theoretical yield.

[0162] Table 2: Y...

Embodiment 3

[0165] Pretreatment in large barrel piston reactors likened to a steam gun

[0166] Corncobs with reduced particle size were prepared as described in Example 1. Pretreatment was carried out as described in Example 2 in a large barrel piston reactor. For pretreatment in the steam injection, the cobs are first loaded into a 9L PEHReactor. The reactor was cooled to 4°C by rotating the outer surface in contact with ice. The reaction vessel was evacuated and diluted ammonium hydroxide solution was injected into the reactor, the ammonium hydroxide was pre-cooled in a cold room at 4 °C and immersed in an ice-water bath through a tube, the ammonia concentration in the reactor was 6 g / 100 g biomass Dry weight, the dry weight concentration of biomass is 45g / 100g total biomass and ammonia water mixture. The PEH Reactor charged with ammonia and corncobs was cooled to 4°C by applying ice to the surface of the rotating reaction vessel and rotating at 4°C for 30 minutes. At this point ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com