Method for preparing natural polyphenol-concentrated sour pear juice and method for preparing sour pear drink

A technology of natural polyphenols and sour pears, applied in food preparation, application, food science, etc., can solve the problem of large loss of antioxidant components polyphenols and achieve the effect of maintaining the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

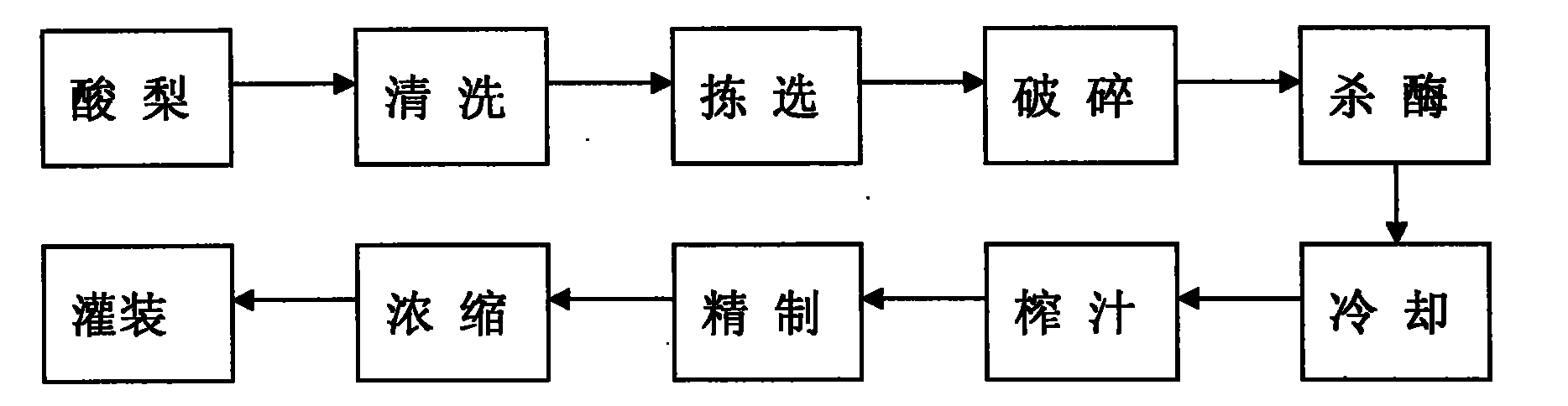

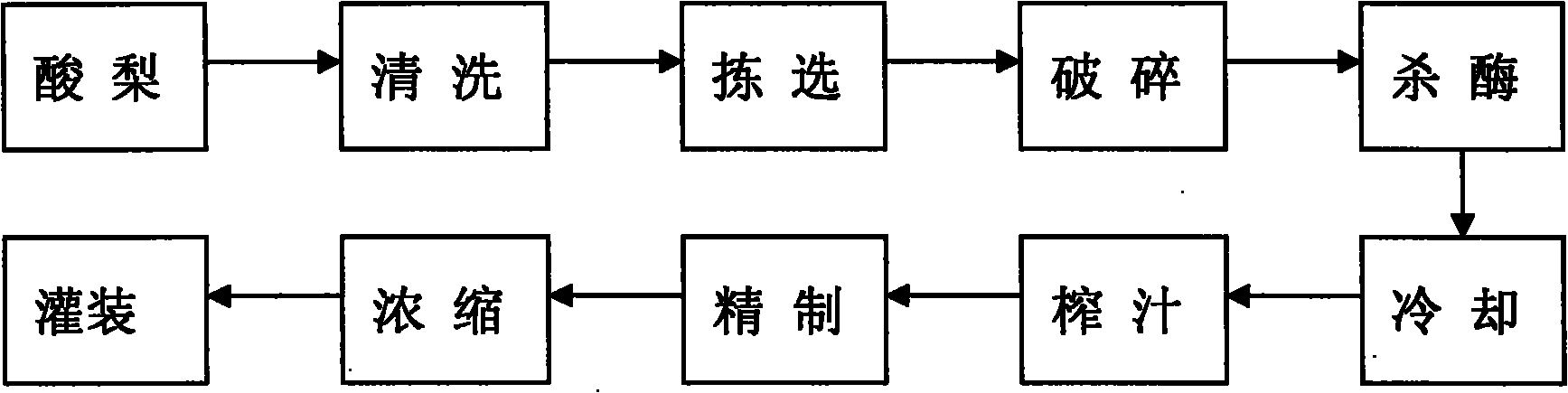

[0029] Example 1: Concentrated sour pear juice

[0030] ①The 1,000kg sour pears that have passed the inspection are transported by water to remove sand and impurities, and then lifted by 2-3 levels and sprayed with clean water, and the sour pears are sent to the sorting table by a conveyor chain. Sour pears are cleaned and sorted by flowing water: the raw materials are washed by tap water, rotten, diseased insects, fruits and impurities are removed, and the sediment is washed away, and then sprayed with pure water for washing.

[0031] ②On the fruit sorting table, pick out the rotten and deteriorated fruits along with the rolling of the fruit, and place the sour pears on the fruit sorting table in a single layer, and the selected raw materials enter the crusher along with the transmission bar.

[0032] ③Crush the washed sour pears into sour pear pulp in a closed crusher. The particle diameter after crushing is 2-4mm, and then input into the pulp heater through a stainless stee...

Embodiment 2

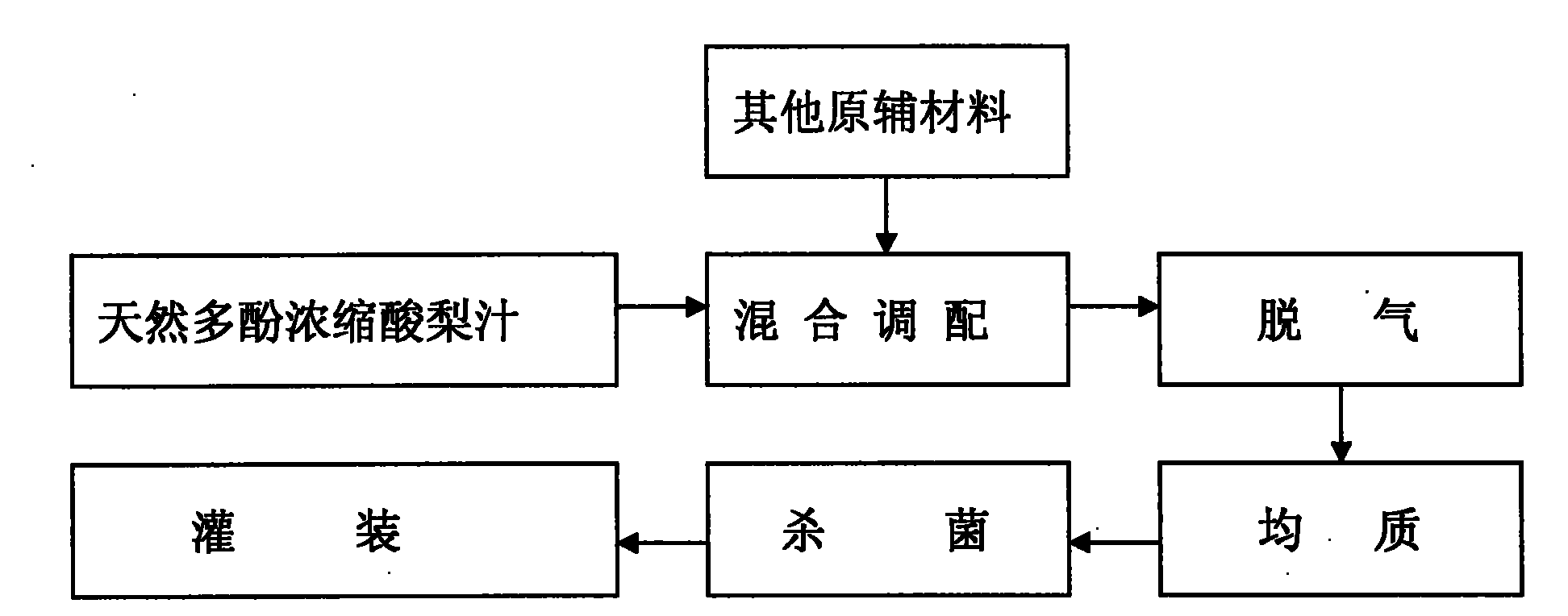

[0039] Embodiment 2: sour pear polyphenol drink

[0040] ①Weigh 100kg of sour pear juice concentrate (60°Brix), 30kg of decolorized and deacidified apple juice, and 870kg of purified water (can be modified by adding essence), so that various raw and auxiliary materials are evenly distributed in the system, and the solubility of the drink is determined. Solids up to 12°Brix, total acid up to 0.9%.

[0041] ② Degassing is carried out under the conditions of pressure 80-150kPa and temperature 30-60°C.

[0042] ③The stabilizing treatment of sour pear drink is carried out homogeneously under the conditions of pressure 10-25Mpa and temperature 40-60°C.

[0043] ④ Pasteurization is used to kill microorganisms;

[0044] ⑤ After sterilization, pour the juice drink into the sterilized hot drink bottle while it is still hot, and seal it immediately.

[0045] ⑥Store in the dark, oxygen-isolated and refrigerated conditions.

Embodiment 3

[0046] Embodiment 3: Extract sour pear juice from sour pear pomace

[0047] ① Dry 2000g of sour pear wet residue after juicing at 55-65°C, turn it from time to time, or dry it in the sun until the moisture content is about 8%, and obtain 480g of dried sour pear residue.

[0048] ②Crush the dried sour pear pomace, then pass through a 40-mesh sieve, and set aside.

[0049] ③Put the pulverized sour pear residue into a 10L extraction tank, add 7000kg of 60% ethanol, and extract for 2 hours at a temperature of 70°C.

[0050] 4. Centrifuge the material in the extraction tank at 4000rpm to collect 5420g of supernatant, add 3500g of 60% ethanol to the precipitate, extract once more (2 hours) at 70°C, and centrifuge to obtain 3540g of supernatant.

[0051] ⑤ Combine the centrifuged supernatants twice, vacuum concentrate and dehydrate and dry at 50-60° C. to obtain 240 g of paste-like polyphenol extract, and the total phenol content can reach more than 60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com