Deodorization device and method thereof

A spraying device and odor technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of difficulty in meeting the requirements of large-scale garbage disposal, high equipment operating costs, and low processing efficiency, and achieve suspension The effect of prolonged time, low equipment operation cost, and increased gas-liquid contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

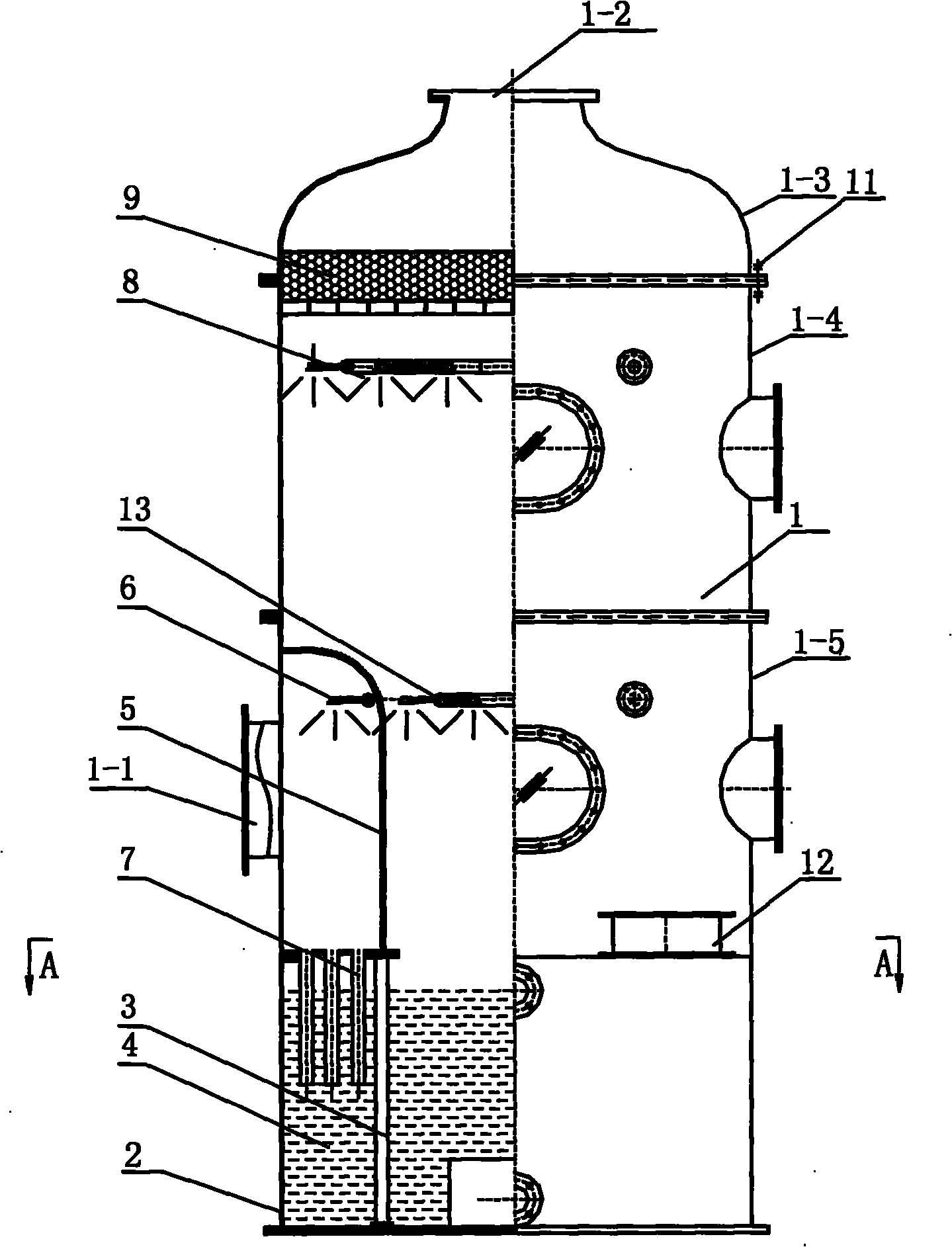

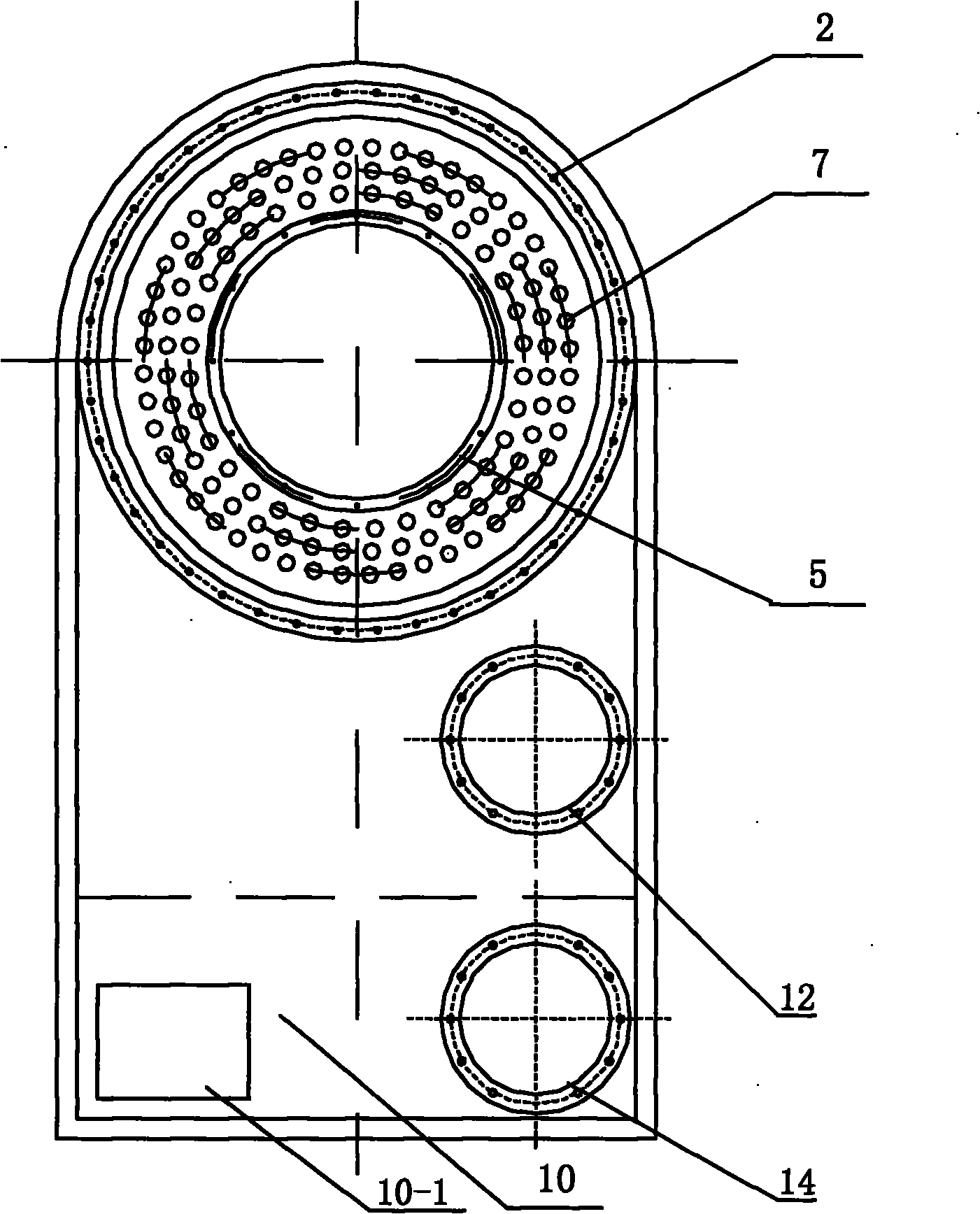

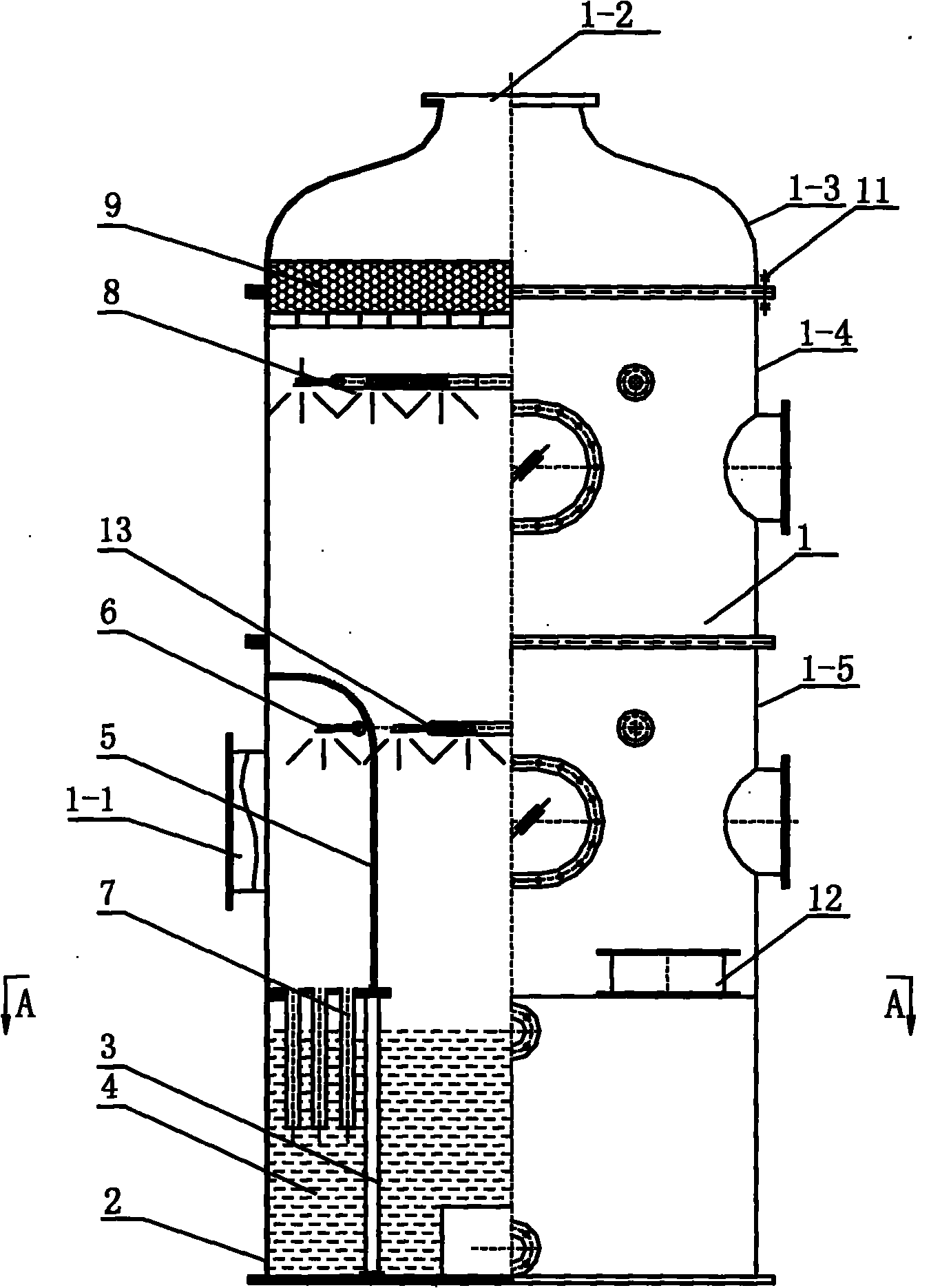

[0036] Such as figure 1 and figure 2 The specific embodiment of the shown deodorizing device of the present invention has a tower body 1, a circulating liquid tank 2, a circulating pump (not shown in the figure), a high concentration solution tank 10 and a solution pump (not shown in the figure) , the tower body 1 is located above the circulating liquid tank 2, the circulating liquid tank 2 is equipped with potassium permanganate solution 4, the high concentration solution tank 10 is equipped with a high concentration potassium permanganate solution, and the high concentration solution tank 10 is provided with a feeding port 10-1, the suction port of the solution pump is submerged in the high-concentration potassium permanganate solution, and the liquid outlet of the solution pump is connected to the circulating liquid tank 2. The lower part of the tower body 1 has an inner cylinder 5, the upper end of the inner cylinder 5 is sealed and fixedly connected with the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com