Method for using higher standing wave resonance for quantitatively detecting thickness of elastic plates

A quantitative detection, elastic plate technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problems of shallow detection depth, inability to detect the surface corrosion of non-conductive materials, and needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

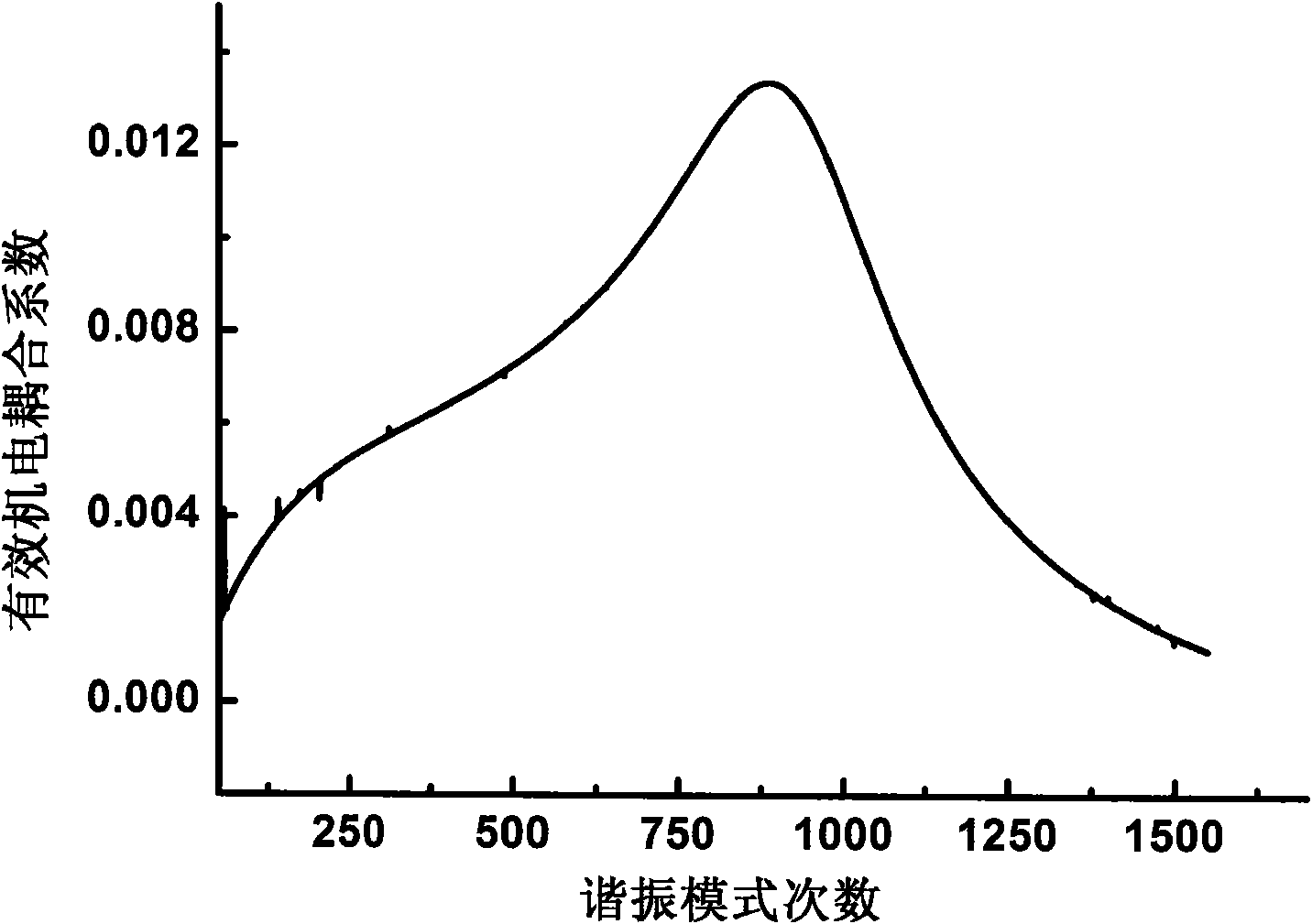

[0062] Take the aluminum plate with the thickness of the tested elastic plate in the range of about 20cm, and its density is 2700kg / m 3 , The longitudinal wave speed is 6420m / s, if the material is the thickness direction sheet-shaped longitudinal wave piezoelectric transducer of zinc oxide (density is 5680kg / m 3 , The longitudinal wave velocity is 6400m / s, the electromechanical coupling coefficient is 0.3), then according to Vl sb / V sb l>100, the thickness of the selected sheet-shaped longitudinal wave piezoelectric transducer is about 0.2mm.

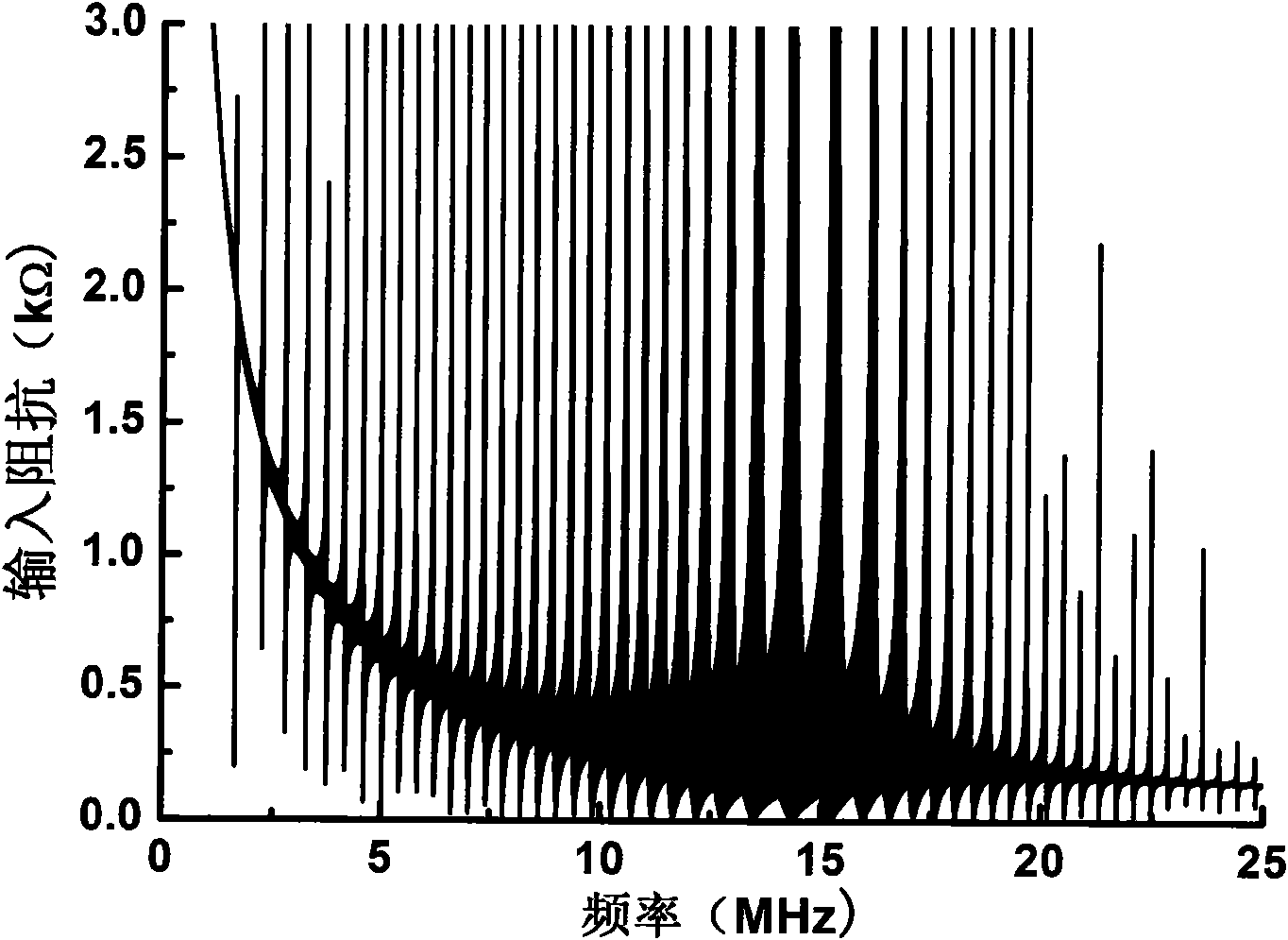

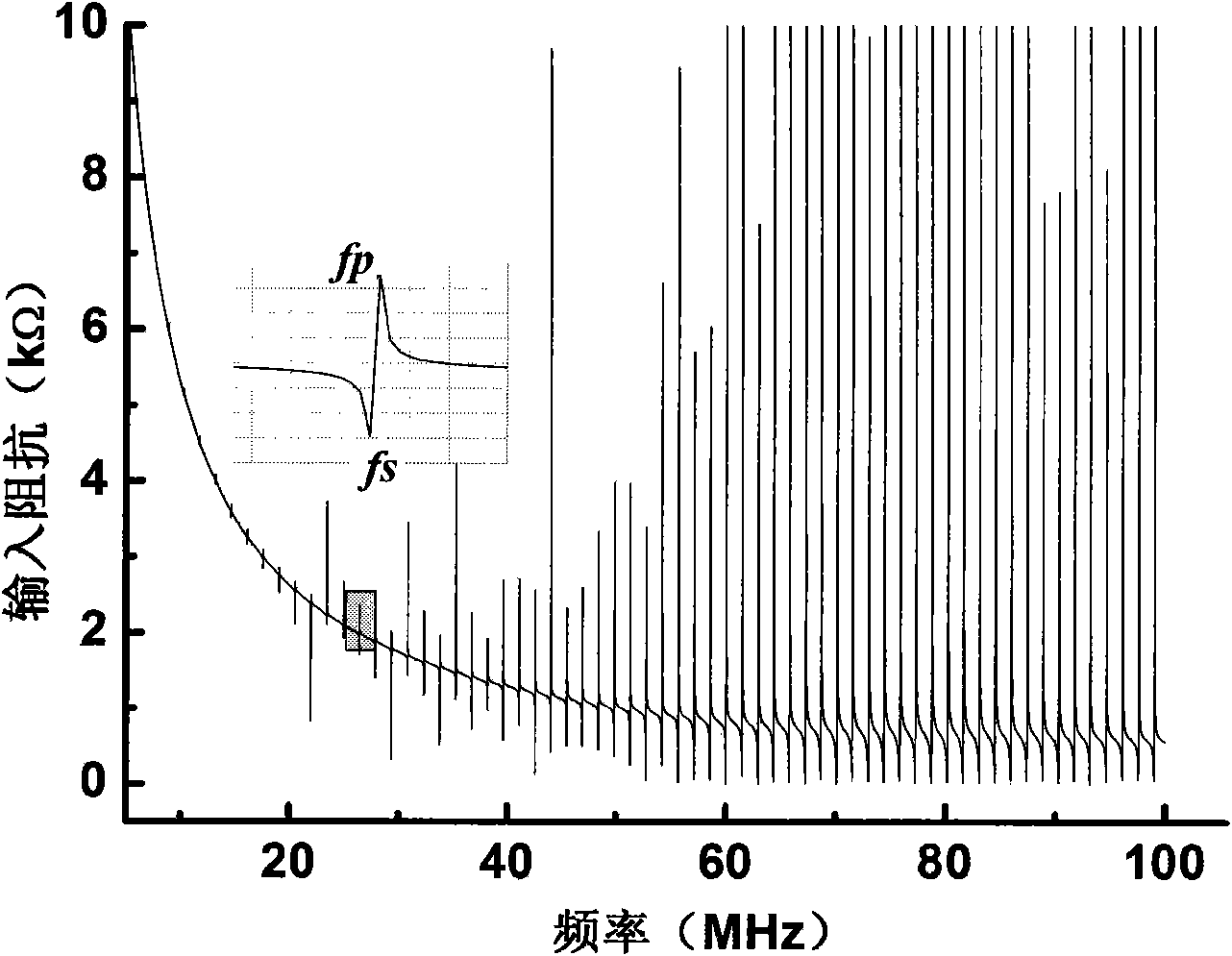

[0063] The thickness detection accuracy of the elastic plate is required to be 20μm. Use the known plate-shaped piezoelectric layer and the material constant of the elastic plate to be tested, and set l a Take 20cm and d and take 20μm into formulas (2) and (3) to determine the frequency resolution of the impedance analyzer or network analyzer f min About 1kHz; using the impedance frequency spectrum spliced after segmented continuous sca...

Embodiment 2

[0066] Take the steel plate whose thickness range of the tested elastic plate is about 20cm, and its density is 7800kg / m 3 , The longitudinal wave velocity is 5900m / s, if the material is PZT5 thickness direction sheet longitudinal wave piezoelectric transducer (density is 7000kg / m 3 , The longitudinal wave velocity is 2400m / s, the electromechanical coupling coefficient is 0.6), according to Vl sb / V sb l>100, according to Vl sb / V sb If l>100, the thickness of the sheet-shaped longitudinal wave piezoelectric transducer is about 0.8mm.

[0067] The thickness detection accuracy of the elastic plate is required to be 20μm. Use the known plate-shaped piezoelectric layer and the material constant of the elastic plate to be tested, and set l a Take 20cm and d and take 20μm into formulas (2) and (3) to determine the frequency resolution of the impedance analyzer or network analyzer f min Is 38Hz; the impedance frequency spectrum spliced after segmented continuous scanning (such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com