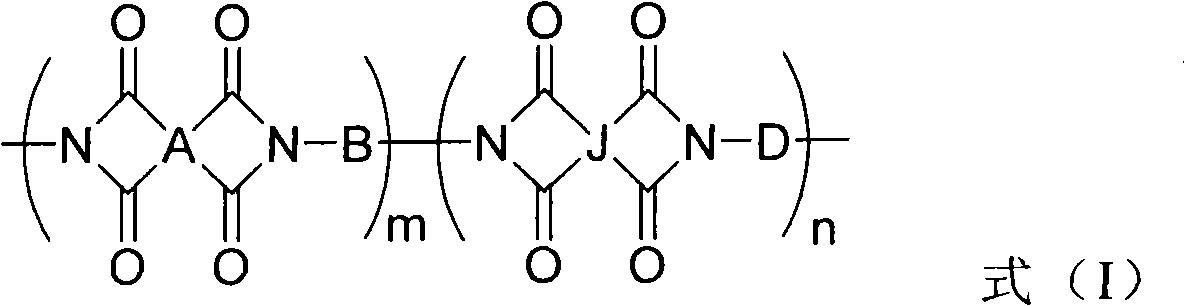

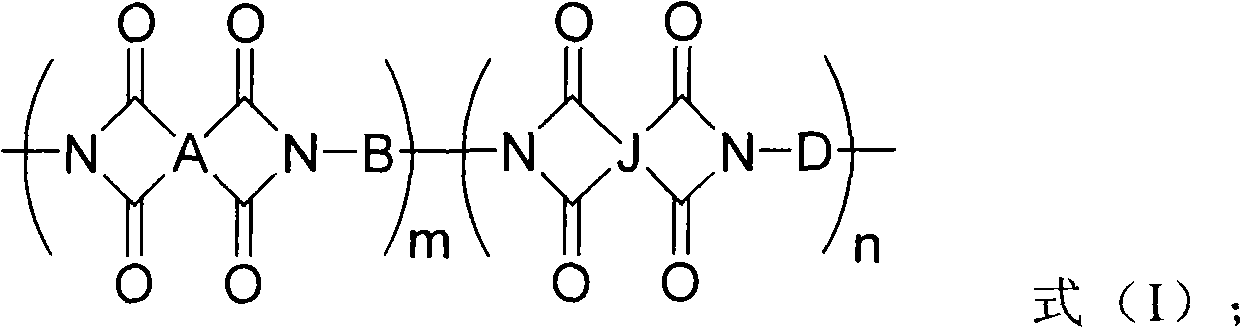

Photosensitive resin composition and application thereof

A technology of photosensitive resin and composition, applied in the field of photosensitive resin composition, can solve the problems of circuit pattern distortion, polyimide ring opening, film shrinkage, etc., and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

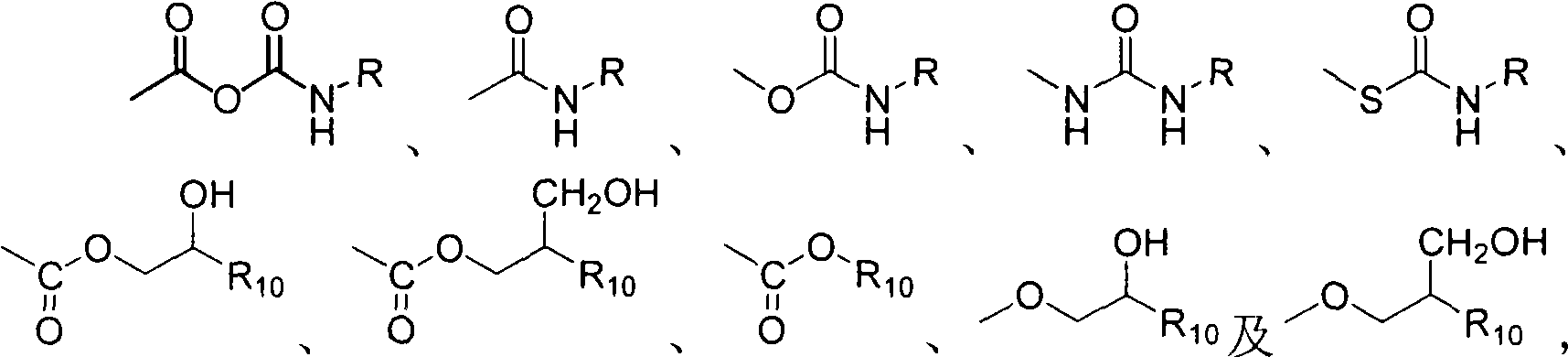

Method used

Image

Examples

Embodiment 1

[0200] Weigh 88.85 g (0.2 mol) of 6FDA, 28.63 g (0.1 mol) of BAPA and 23.03 g (0.1 mol) of MEMG, add 300 ml of NMP, stir at room temperature for 1 hour, then raise the temperature to 50°C and stir for 4 hours. Afterwards, 50 ml of xylene was added, and water was removed with a Dean-Stark apparatus at 150°C. After the water is completely removed, polyimide P1 with hydroxyl groups is obtained.

Embodiment 2

[0202] Weigh 100.074 g (0.2 mol) of DA1 and 42.46 g (0.2 mol) of DMDB, add 450 ml of NMP, stir at room temperature for 1 hour, then raise the temperature to 50°C and stir for 4 hours. Afterwards, 50 ml of toluene was added, and water was removed with a Dean-Stark apparatus at 130°C. After the water is completely removed, polyimide P2 with hydroxyl groups is obtained.

[0203] (B) Synthesis of polyimide modified by diisocyanate

Embodiment 3

[0205] Weighed 490 g of the polyimide P1 prepared in Example 1, added 0.85 g of 1-MI, 6.51 g of HEMA, 11.12 g of IPDI and 0.11 g of PTZ, and stirred at room temperature for 1 hour. Thereafter, the temperature was raised to 60° C., and the mixture was stirred for 6 hours to obtain photosensitive polyimide P3 whose hydroxyl group was modified with diisocyanate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com