Lead-acid battery and manufacturing method thereof

A technology for lead-acid batteries and manufacturing methods, applied in the direction of lead-acid batteries, lead-acid battery construction, final product manufacturing, etc., can solve the problem that lithium batteries and nickel-metal hydride batteries are expensive, safety problems have not been completely solved, and cannot be well adapted Electric vehicles and other problems, to achieve the effect of not easy appearance, more cycle times, and long discharge time with high current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

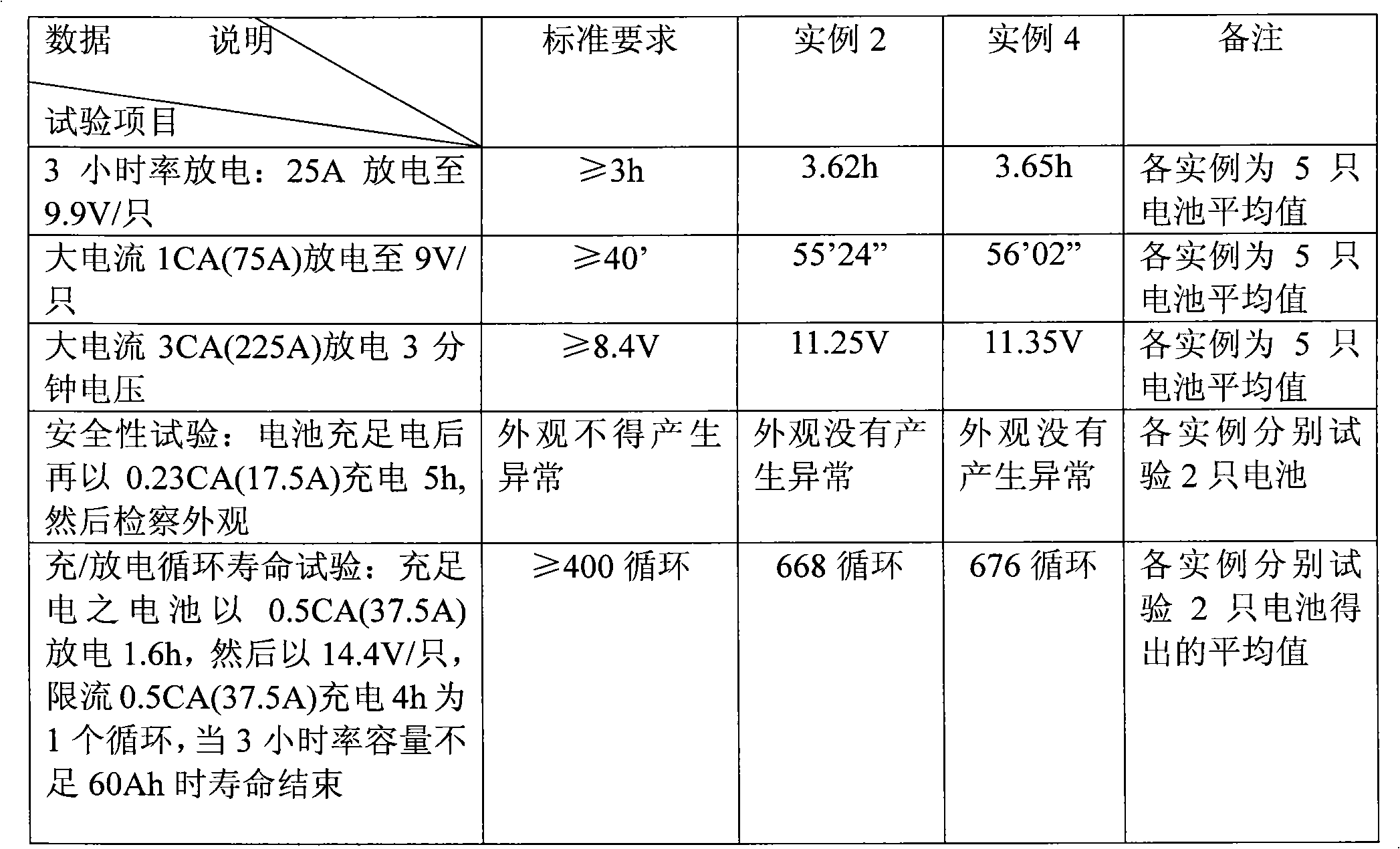

Examples

Embodiment 1

[0051] A kind of manufacture method of lead-acid storage battery, specifically the method for manufacturing 6ERV~75 (3Hr) lead-acid storage battery for road electric vehicle, it comprises the following steps:

[0052] (1) Make the battery case cover: the battery case and the battery cover are made of ABS engineering plastics, the battery case and the battery cover are sealed and connected by glue, and the battery cover is also equipped with a cover sheet. The length, width and height of the battery are 563± 4mm, 114±4mm, 188±4mm, that is, L=563±4mm, W=114±4mm, H=188±4mm; the positive terminal 21 and the negative terminal 22 of the battery are located at the same end of the battery cover 2, which is convenient for installation car wiring;

[0053] (2) Preparation of polar plates:

[0054] (2.1) Prepare the positive grid: the positive grid is made of alloy material Pb-Ca-Sn-Al, wherein the weight percentage of each component of the Pb-Ca-Sn-Al alloy is: Sn is 1.45% to 1.55%; Ca...

Embodiment 2

[0072] A kind of lead-acid storage battery, it is made according to the method for embodiment 1.

Embodiment 3

[0074] A method for manufacturing a lead-acid storage battery, the main difference from Example 1 is that (2.3.1) preparation of positive plate lead paste, (2.3.2) preparation of negative plate lead paste, (2.4.1) paste three steps The proportions of each component of the raw materials used in the process are different, and the specific methods of these three steps are:

[0075] (2.3.1) Preparation of positive plate lead paste: take lead powder 1010Kg, Bi 2 o 3 0.5Kg, SnSO 4 0.7Kg, Sb 2 o 3 0.8Kg, graphite 2.5Kg, polyester staple fiber 0.9Kg, specific gravity 1.400±0.2 sulfuric acid 90Kg and pure water 112Kg to make positive plate lead paste;

[0076] (2.3.2) Preparation of negative plate lead paste: take lead powder 1010Kg, BaSO 4 9Kg, lignin 3.5Kg, humic acid 2.5Kg, SnO 2 0.5Kg, acetylene black 5.5Kg, polyester staple fiber 0.9Kg, specific gravity 1.400±0.2 sulfuric acid 95Kg and pure water 120Kg to make negative plate lead paste;

[0077](2.4.1) Paste applicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com