Laser diode assembly

A laser diode and assembly technology, applied in radiation therapy, treatment, etc., can solve the problems of complicated assembly work, increased manufacturing cost, and easy damage, and achieve excellent moisture resistance and waterproof performance, easy assembly and separation, and easy maintenance and The effect of replacement

Active Publication Date: 2010-08-25

沈阳碧根医疗器械有限公司

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention solves the problem that when the laser diode assembly is applied to medical and health care products, its drive circuit substrate is easily damaged due to overheating, the irradiation rate of laser light collection or diffusion is low, and its assembly work is very complicated, which increases the manufacturing cost. ; And when the product needs maintenance, due to the inconvenient replacement and disassembly of diodes, etc., the maintenance and warranty efficiency is very low and other technical problems, the following solutions are provided:

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

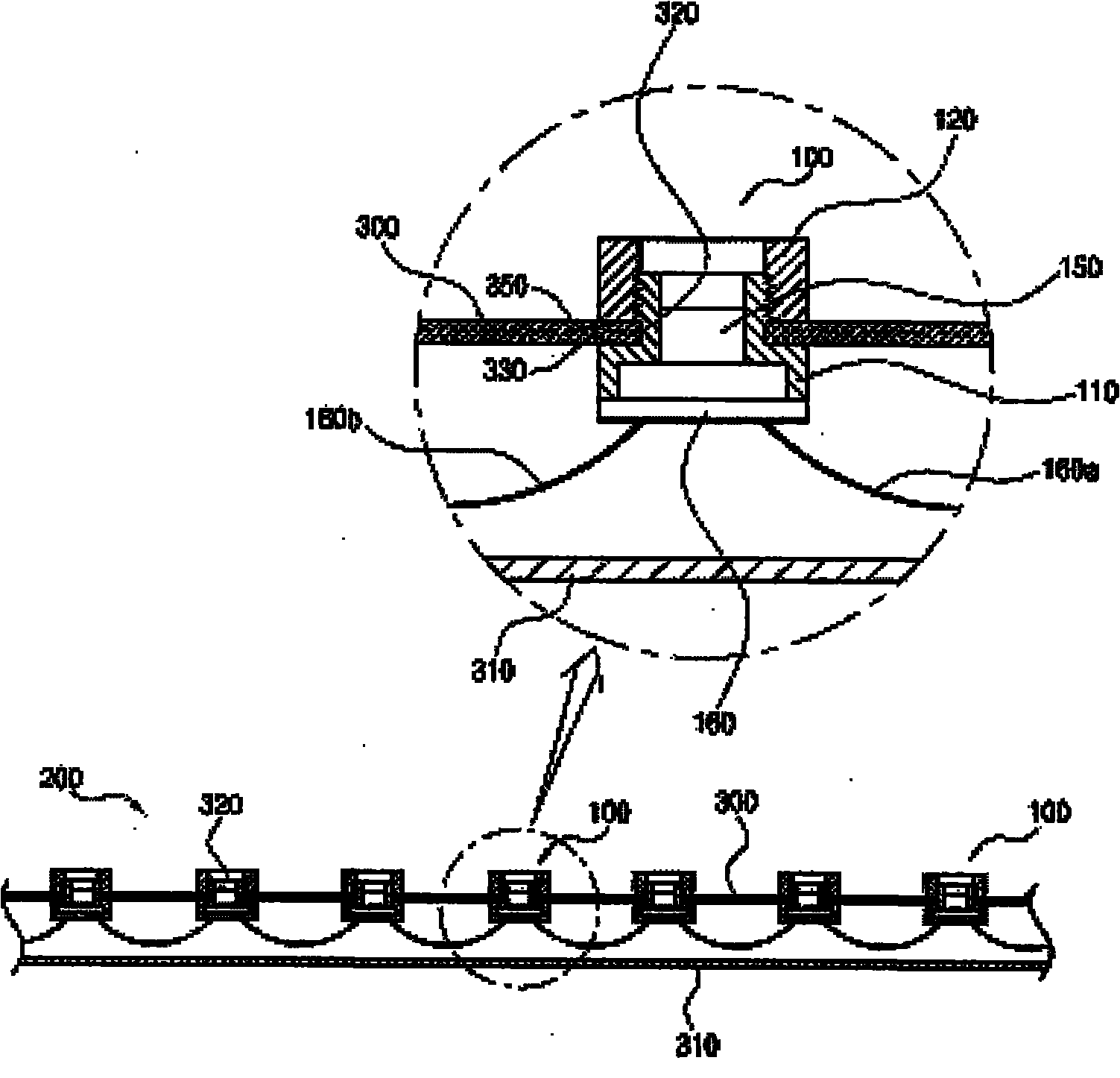

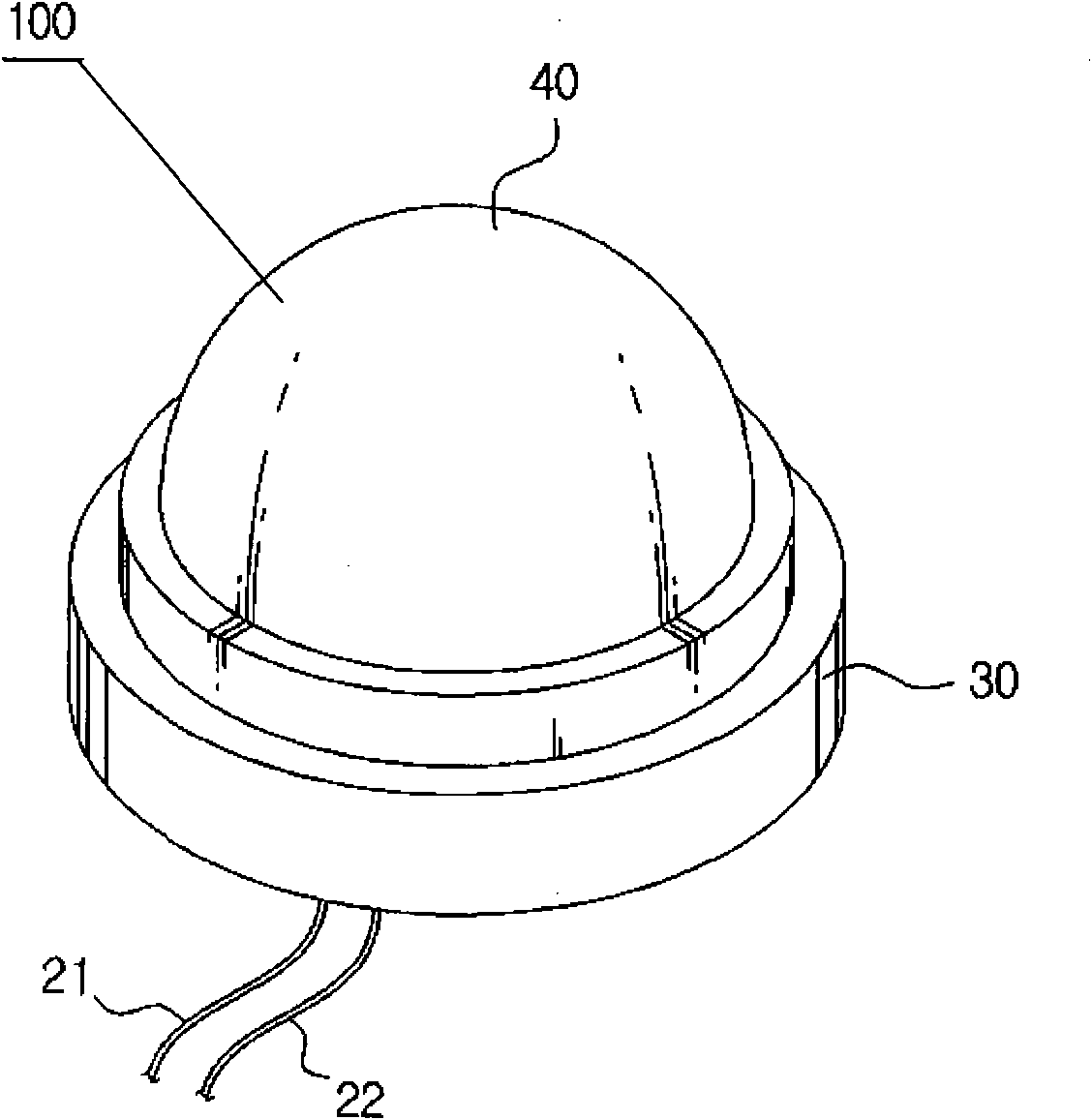

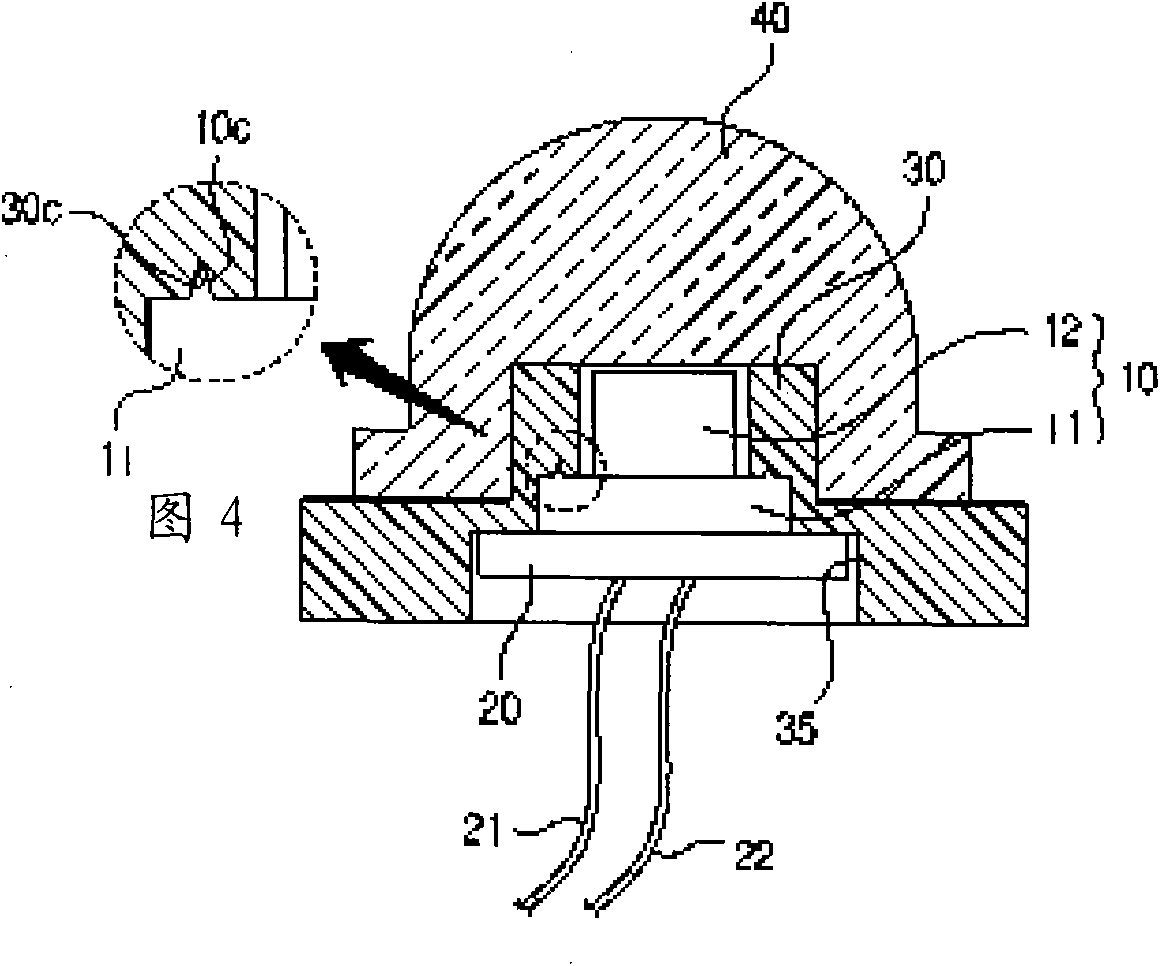

A laser diode assembly is designed in order to solve the following technical problems: the printed circuit substrates of the existing laser diode assemblies are liable to damage due to overheat, the light sources emitted by the laser diodes have low concentration rate or diffusion irradiation rate, and assembly, maintenance and change are inconvenient when the laser diode assemblies are applied to medical and health care products. The laser diode assembly is assembled on various medical and health care products as the main component by a sleeve matched with the laser diode assembly. Not only the laser diode assembly is convenient to assemble, but also the light source emitted by the laser diode assembly has good concentration effect or diffusion irradiation effect, thus ensuring storage and maintenance to be easier. Meanwhile, the heat energy generated by the laser diode assembly is released more efficiently and the effect is better when the released heat is applied to disease treatment or health care. Various products assembled by the laser diode assembly by utilizing the sleeve not only are convenient to assemble but also have excellent waterproof and dustproof properties.

Description

Laser Diode Assembly Technical field: The invention relates to a laser medical health care product component and its use, in particular to a laser diode assembly and a laser diode assembly with a cover. It is mainly used as the main component of laser mattresses, belts, hats, etc. as medical and health care products. Background technique: As we all know, Laser Diode (LD, LaserDiode) utilizes the photoconductive effect of compound semiconductors. It has not only been applied to the measurement of optical communication OA and AV, but has recently been expanded to the medical field. Photo-chemical actions on plants can be seen in charcoal assimilation. When light is irradiated to a living body, ATP is generated by optical action to activate cells. Due to the low intensity of the wavelength generated by the laser, there is no damage to the biological cells under the irradiation of the laser. Treatments such as relieving pain by inducing physiological activation of living or...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A61N5/067

Inventor 郑惠淑白荣宽

Owner 沈阳碧根医疗器械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com