Submicron hard alloy and preparation method

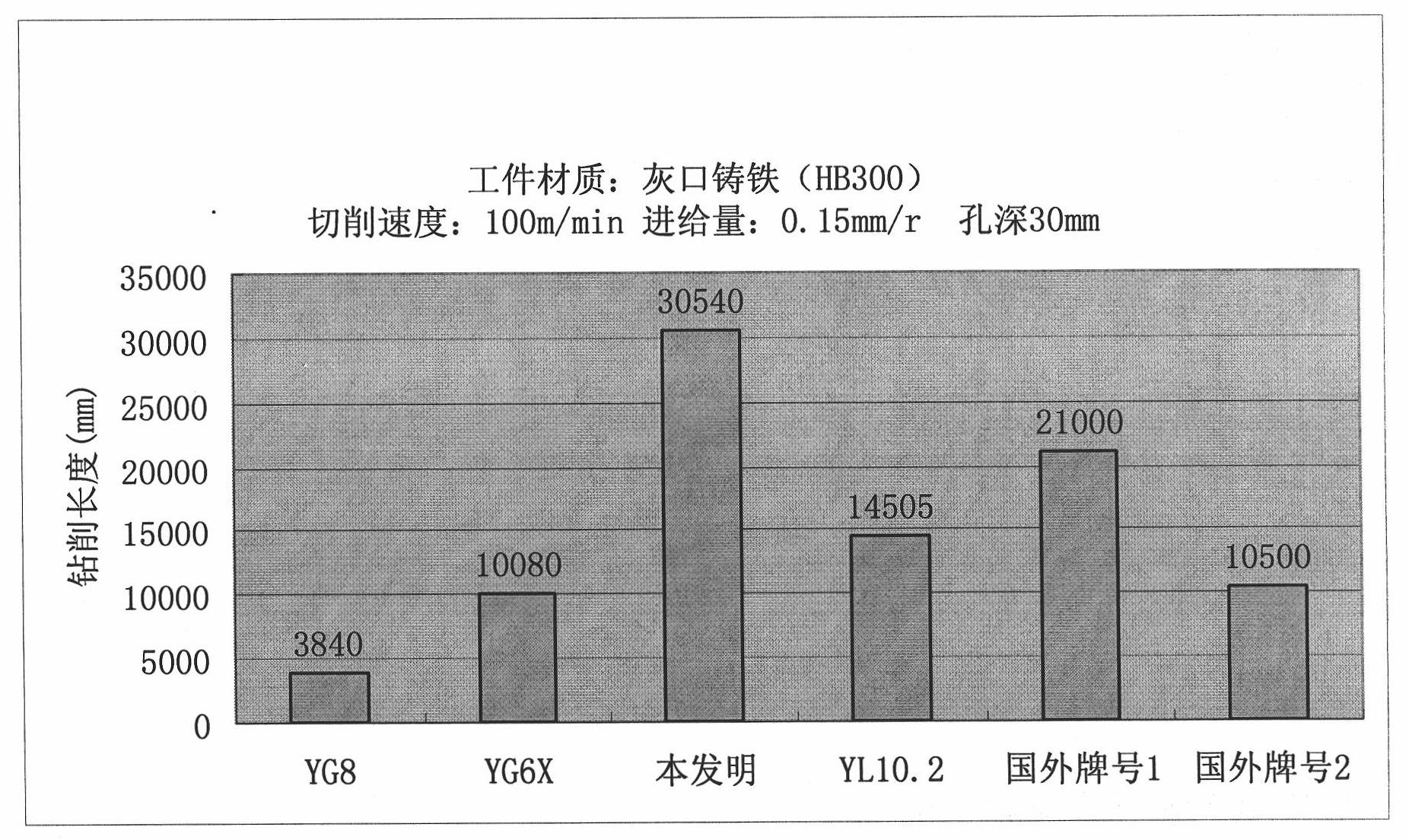

A cemented carbide and micro technology, applied in the field of high-performance sub-micron cemented carbide and its preparation, can solve the problems of insufficient fracture toughness, elimination, low single batch output, etc., achieve high cutting efficiency and service life, and improve wear resistance. The effect of high resistance and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

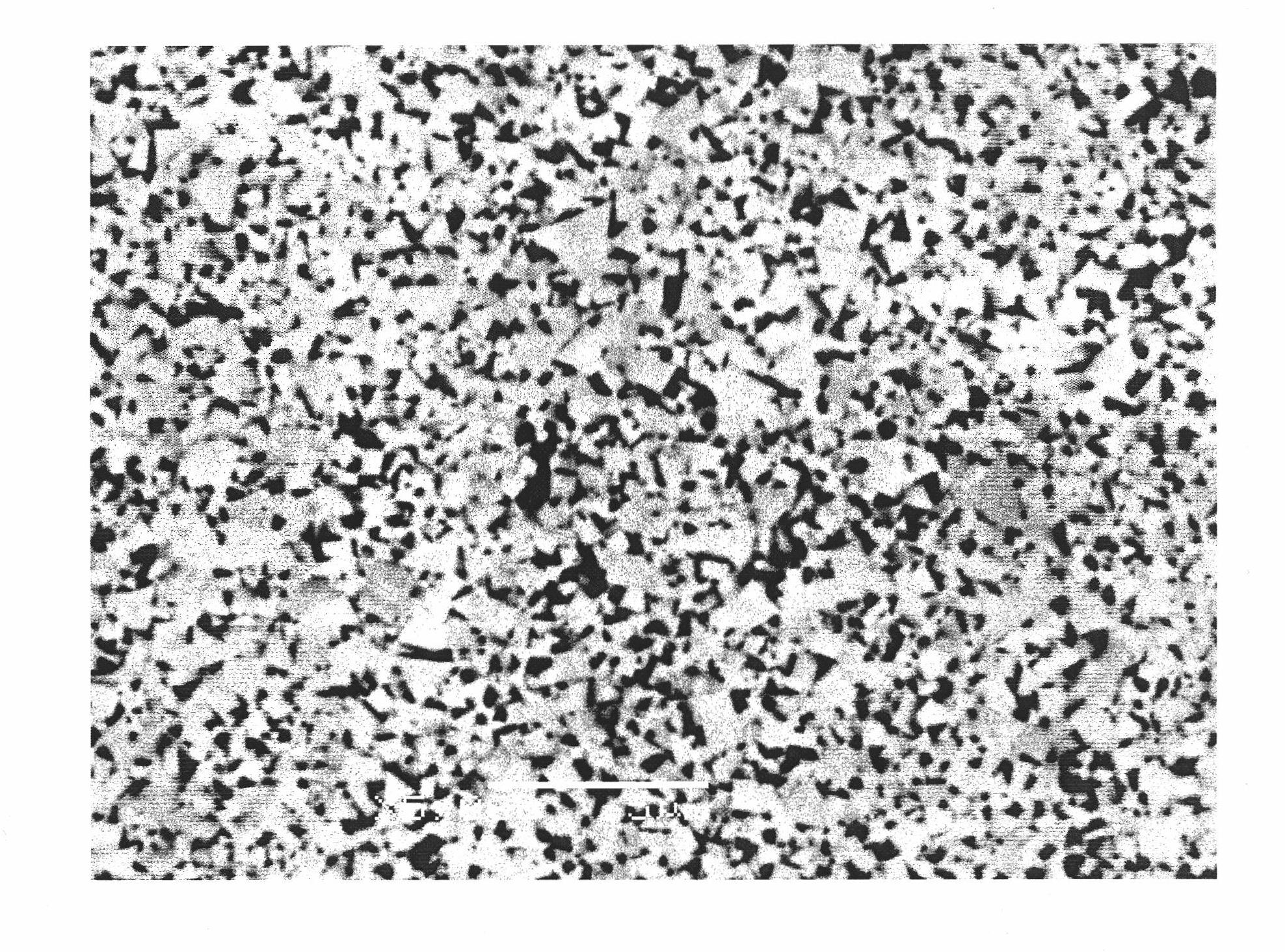

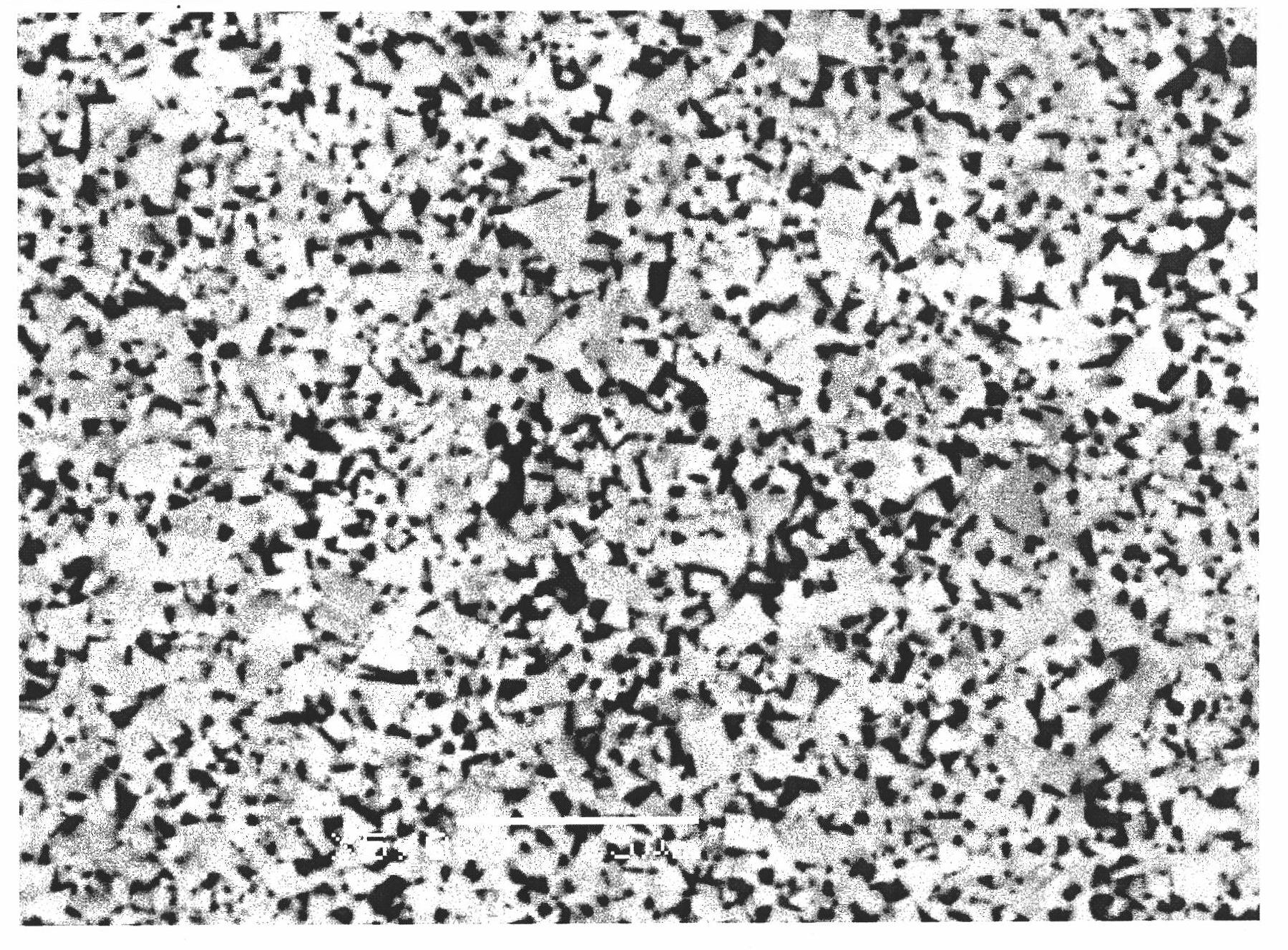

[0017] Embodiment 1: during batching, raw material powder composition is -- the Co powder of 8wt% (Fischer particle size 1.0 μ m), the Cr of 0.4wt% 3 C 2 powder, 0.25wt% VC powder, and the balance is 0.8 μm WC powder. Ethanol is used as the grinding medium, polyethylene glycol is used as the molding agent, the ball-to-material ratio is 5:1, the speed of the ball mill is 36 rpm, the mixture is ground for 30 hours, and spray-dried to obtain the mixture. The temperature is 75bar, and the holding time is 56min. The metallographic phase of the prepared submicron cemented carbide is shown in Figure 1 (the following examples are the same), the grain size is 0.8μm, the WC grains grow completely and have few defects, and its HV 3 1780, φ3.25*38.5mm standard sample (the same as the following examples) bending strength is 4320N / mm 2 .

Embodiment 2

[0018] Embodiment 2: during batching, raw material powder is composed of——7.2wt% Co powder (Fisher particle size 1.5 μm), 0.5wt% Cr 3 C 2 powder, 0.4wt% VC powder, and the balance is 0.7μm WC powder. Acetone was used as the grinding medium, paraffin was used as the molding agent, the ball-to-material ratio was 6:1, the speed of the ball mill was 40 rpm, the mixture was ground for 45 hours, and spray-dried to obtain the mixture. The holding time is 30min, the prepared submicron cemented carbide has a grain size of 0.7μm, the WC grains grow completely and have few defects, and its HV 3 It is 1860, and the bending strength is 4130N / mm 2 .

Embodiment 3

[0019] Embodiment 3: during batching, raw material powder composition is -- the Co powder of 8.8wt% (Fischer particle size 1.3 μ m), the Cr of 0.25wt% 3 C 2 powder, 0.15wt% VC powder, and the balance is 0.9 μm WC powder. Hexane was used as the grinding medium, paraffin was used as the molding agent, the ball-to-material ratio was 4.5:1, the speed of the ball mill was 30 rpm, the mixture was ground for 28 hours, and spray-dried to obtain the mixture. , the holding time is 50min, the obtained submicron cemented carbide has a grain size of 0.9μm, the WC grain grows completely and has few defects, and its HV 3 It is 1740, and the bending strength is 4650N / mm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com