Method for simultaneously preparing tetrachloropyridine and diglycolic acid in cathode and anode chambers

A technology of tetraclopyridine and diglycolic acid, applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve problems such as poor product quality, high reaction temperature, and environmental pollution

Inactive Publication Date: 2010-08-25

FUJIAN NORMAL UNIV

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

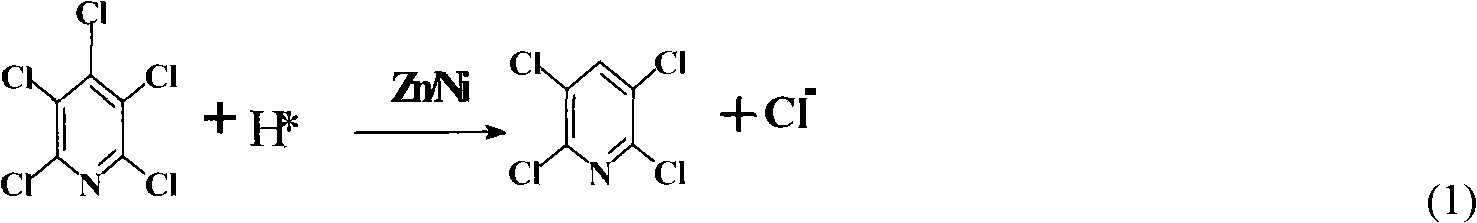

The traditional process adopts zinc powder and hydrochloric acid to reduce pentachloropyridine. The disadvantages of this process are: (1) the reaction temperature is high, and the operation process is dangerous; (2) a large amount of zinc salt is wasted; (3) the cost is high and the environment serious pollution

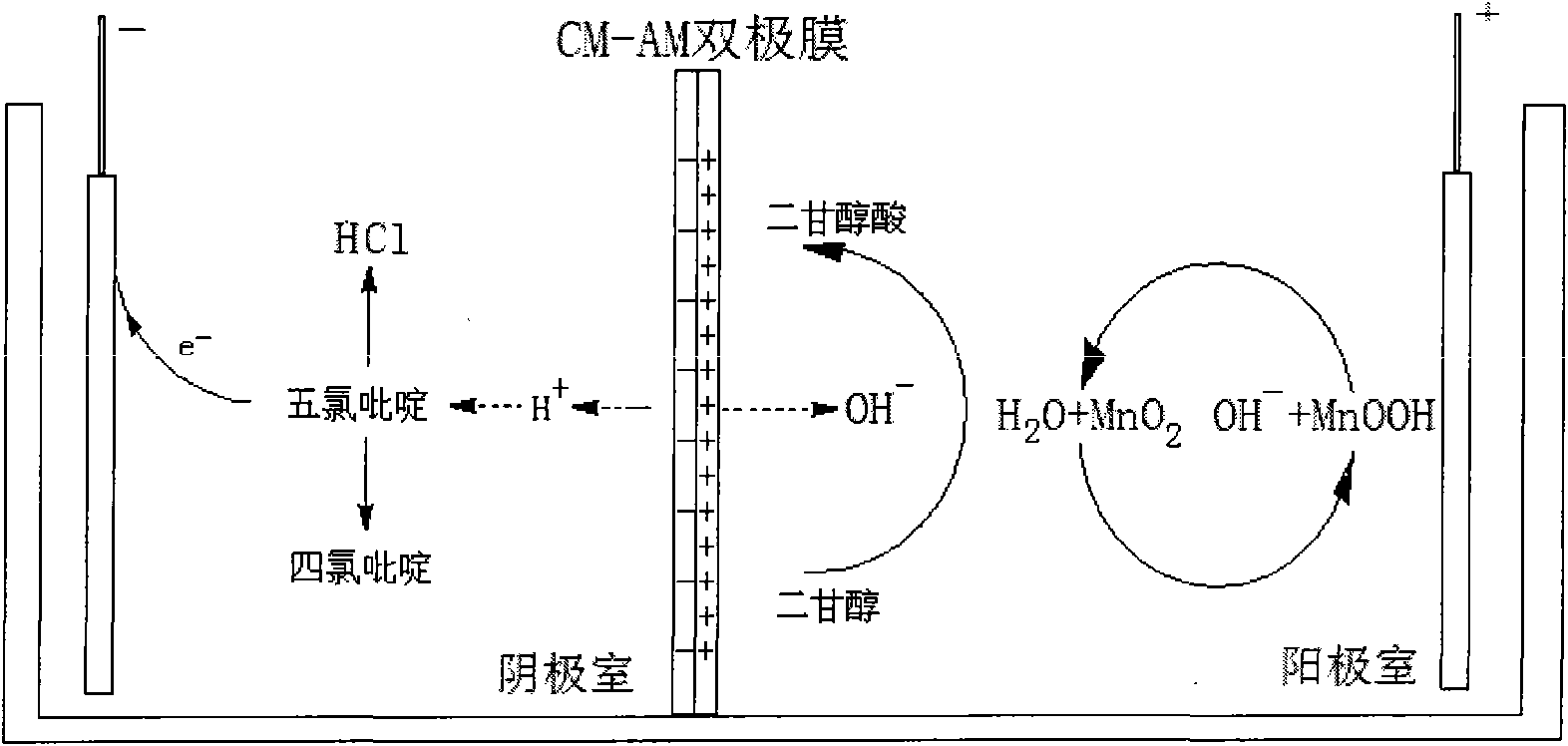

In order to overcome the low yield of 2,3,5,6-tetrachloropyridine synthesis products in the prior art, poor product quality, serious environmental pollution in the production process and high production cost when preparing diglycolic acid by nitric acid oxidation method To solve the problem of serious environmental pollution, this technology proposes to use the bipolar membrane as the diaphragm of the electrolytic cell and the cleanest reagent electron as the chemical reagent to prepare 2,3,5,6-tetrachloropyridine in the cathode chamber and prepare The Diglycolic Acid Method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the field of environment-friendly, energy-saving and emission-reducing electrochemical synthesis, in particular to a method for preparing 2,3,5,6-tetrachloropyridine in a cathode chamber and diglycolic acid in an anode chamber based on bipolar membrane technology. The method is characterized in that the electrolyte in the cathode chamber contains 0.5 mol / L of aqueous solution of pentachloropyridine tetrahydrofuran sodium acetate and 3 to 10 g / L of tetramethylammonium bromide; the electrolyte in the anode chamber contains 100 g / L of diglycol, 2 mol / L of NaOH solution and 50 to 500 g / L of MnO2; the electrolysis temperature is between 20 and 65 DEG C, the current density is between 16 and 36 mA.cm<2>; and the electrolysis time is 40 to 80 minutes. The preparation method is environment-friendly, has mild production conditions, and achieves the effect of energy conservation; and the yield sum of the cathode and anode chambers is more than 100 percent.

Description

A method for simultaneously preparing tetraclopyridine and diglycolic acid in anode and cathode chambers technical field The invention relates to the field of electrochemical synthesis that is environmentally friendly, energy-saving and emission-reducing. Specifically relate to a method for preparing 2,3,5,6-tetrachloropyridine (2,3,5,6-TCP) in the cathode compartment and diglycolic acid in the anode compartment based on bipolar membrane technology Background technique 2,3,5,6-Tetrachloropyridine is a white powder or crystal, which is a valuable commercial product and an important pharmaceutical and pesticide intermediate. The traditional process adopts zinc powder and hydrochloric acid to reduce pentachloropyridine. The disadvantages of this process are: (1) the reaction temperature is high, and the operation process is dangerous; (2) a large amount of zinc salt is wasted; (3) the cost is high and the environment serious pollution. Therefore, research on the optimizatio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C25B3/00C07D213/61C07C59/305

CPCY02P20/10

Inventor 陈震陈日耀郑曦陈晓肖艳春

Owner FUJIAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com