Method for preparing metallic titanium by electrolyzing sodium titanate-sodium hydroxide melt

A technology for sodium hydroxide and metal titanium, applied in the field of preparing metal titanium, can solve the problems of high production cost, complicated process, high comprehensive energy consumption, and achieve the effects of low cost, high current efficiency and cost reduction.

Inactive Publication Date: 2010-08-25

冯锦先

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the process of this method is complicated, the flow process is long (it takes 3 to 5 days to produce a furnace product), the production is discontinuous, the energy consumption is high, and the pollution is serious, and the energy consumption for producing metallic magnesium accounts for 30% to 30% of the total energy consumption. 35%, but the utilization rate of magnesium is only 70%, and the current efficiency of electrolytic magnesium is only about 50%

Over the past 50 years, although this method has been improved in terms of raw materials, chlorination process, refining process, reduction, vacuum distillation process, etc., it still has high production costs due to factors such as high comprehensive energy consumption and inability to continue production. Titanium is expensive

However, by analyzing these methods, compared with the methods currently used in industry, although they have been improved, their methods all require high temperature environment and harsh conditions without exception, and the yield is not high. More expensive metals such as calcium and sodium will not reduce the cost too much, and cannot change the current situation where titanium metal has relatively large limitations in industry

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Login to View More

Abstract

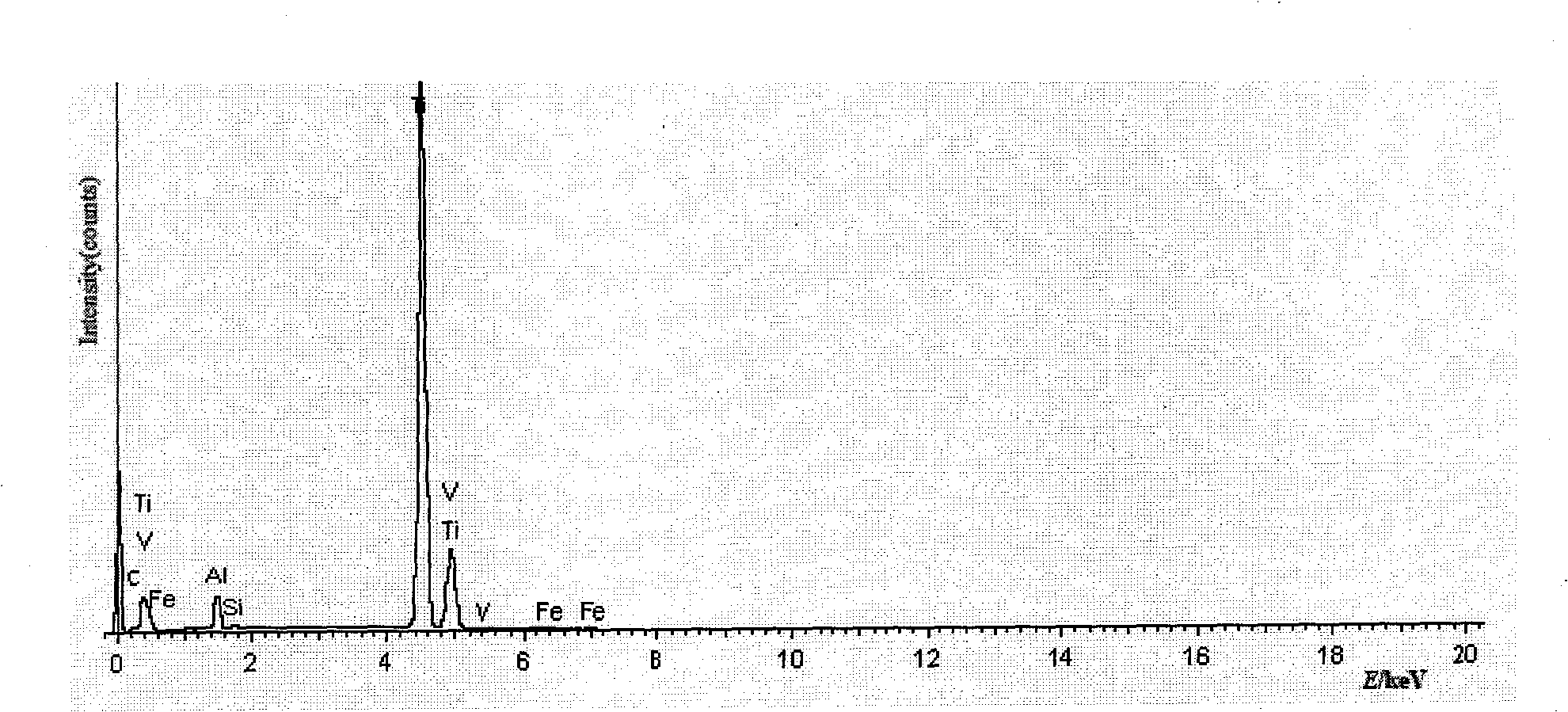

The invention discloses a method for preparing metallic titanium by electrolyzing sodium titanate-sodium hydroxide melt. The method comprises the following steps of: A, uniformly mixing titanium dioxide and sodium hydroxide solid in the mass ratio of 3:10 to 2:5 to obtain a mixture; B, placing the mixture of the titanium dioxide and the sodium hydroxide in the step A into an electrolytic bath, and melting the mixture of the titanium dioxide and the sodium hydroxide under the condition of the heating temperature of between 355 and 460 DEG C to obtain the titanium dioxide-sodium hydroxide melt; C, inserting an electrode in the titanium dioxide-sodium hydroxide melt, firmly fixing the electrode, and electrolyzing the melt under the condition that the voltage is 5 to 12 and the current intensity is 5 to 6 A; and D, taking gray matter which is generated at the cathode out, washing the gray matter in water, filtering and drying the gray matter to obtain the metallic titanium. The method has the advantages of simple operation and low cost.

Description

technical field The invention relates to a method for preparing titanium, in particular to a method for preparing metallic titanium by electrolysis of sodium titanate-sodium hydroxide melt. technical background Titanium and its alloys have excellent physical and chemical properties such as low density, corrosion resistance, and high temperature resistance. The world's titanium industry is undergoing a transition from a single model with aerospace as the main market to a multi-model that focuses on the development of metallurgy, energy, transportation, chemical industry, biomedicine and other civilian fields. The excellent performance of titanium has prompted human beings to urgently need it. The biggest disadvantage of titanium is that it is difficult to refine. When smelting titanium, you have to go through complicated steps: turn ilmenite into titanium tetrachloride, put it in a sealed stainless steel tank, fill it with argon gas, and make them react with metal magnesium...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C25C3/28

Inventor 冯锦先

Owner 冯锦先

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com