Cooling device for engine and/or gearbox oil, in particular of a combustion engine

A technology of cooling device and engine oil, which is used in engine cooling, machine/engine, engine lubrication, etc., can solve problems such as large structure space, and achieve the effect of high oil cooling efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

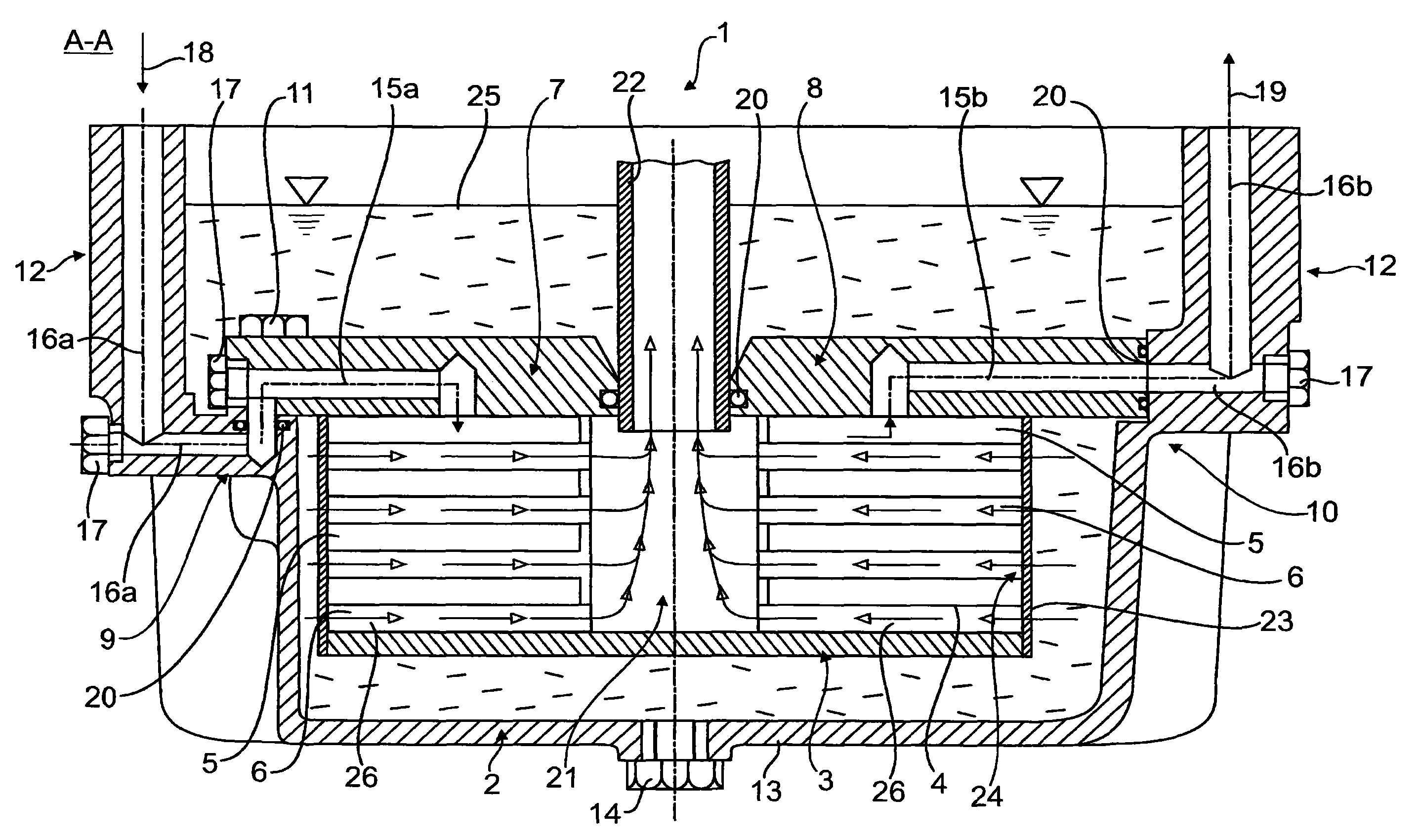

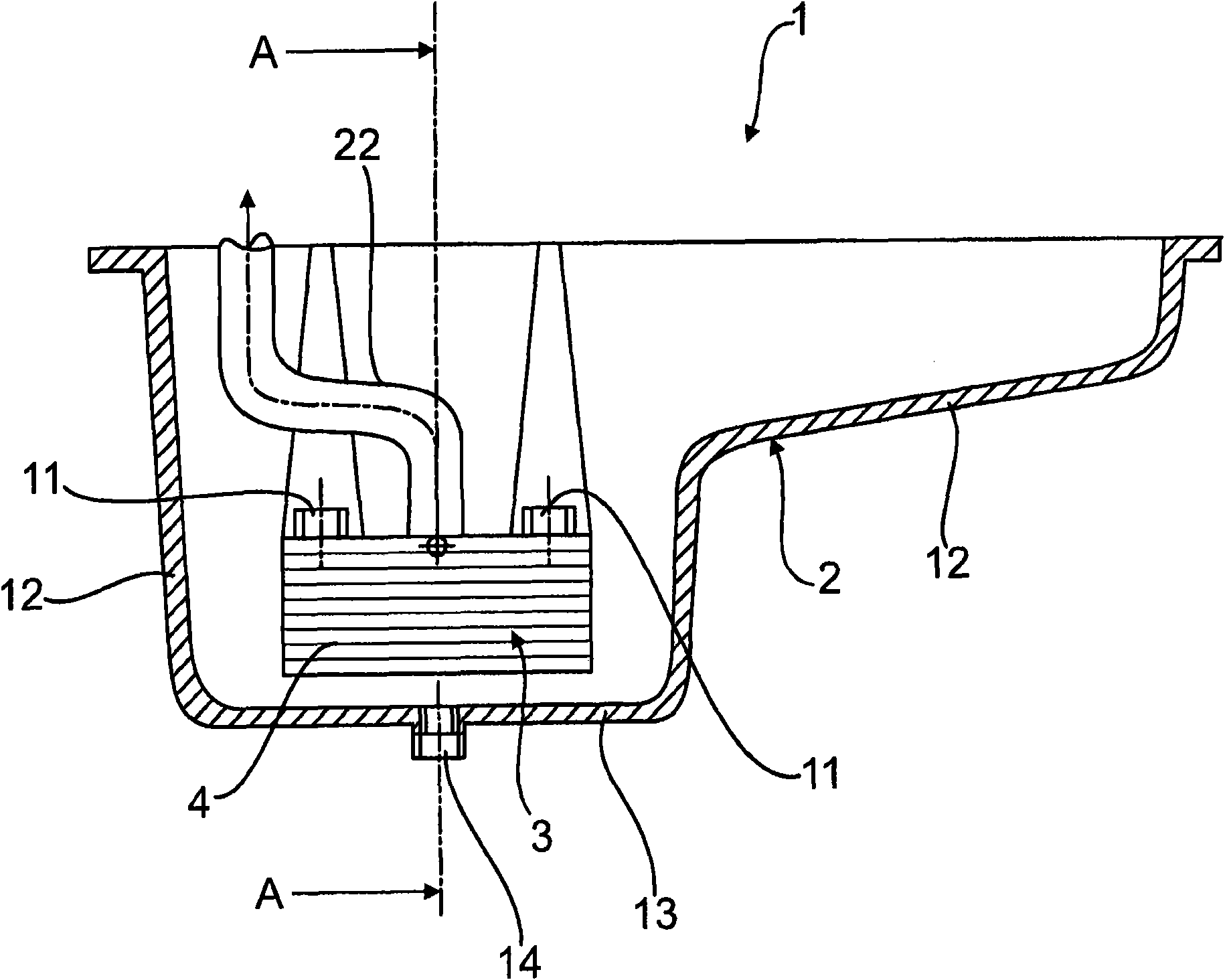

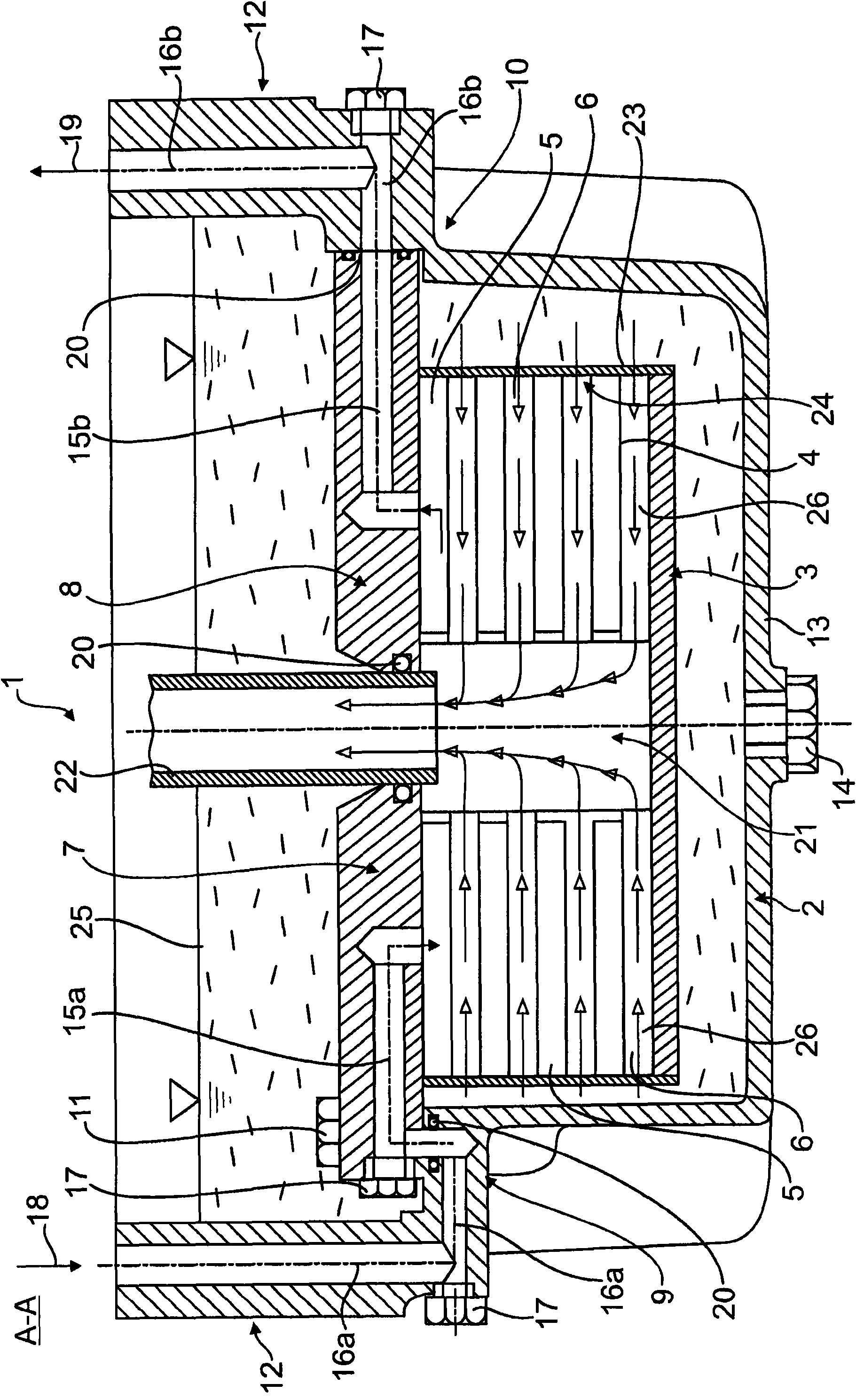

[0026] 1 and 2 schematically show different cross-sectional views through a first embodiment of a cooling device according to the invention. The cooling device 1 comprises a support as an oil cooler and a plate heat exchanger 3 arranged in an oil sump 2 .

[0027] In particular, as can be seen from FIG. 2 , the plate heat exchanger 3 is formed in particular from a stack of several flat plates 4 which on the one hand form the plate intermediate space 5 for supplying the coolant and on the other hand form the supply supply. Oil plate type intermediate chamber 6.

[0028] The plate heat exchanger 3 is thus supported on the bearings 9 , 10 on the side of the oil tank by means of the support elements 7 , 8 on the side of the heat exchanger and fixed, for example by means of screw connections 11 , so that the heat exchanger 3 not only A distance is maintained with respect to the side wall 12 and with respect to the bottom 13 in which usually an oil drain cock 14 is arranged.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com