300mm vertical oxidation furnace quartz boat rotary device

A technology of rotating device and oxidation furnace, which is applied to vertical furnaces, furnaces, furnace types, etc., can solve the problems of silicon wafer surface temperature, uneven gas concentration, and affect product quality, achieve uniform temperature and air flow, and improve processing quality , position control precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

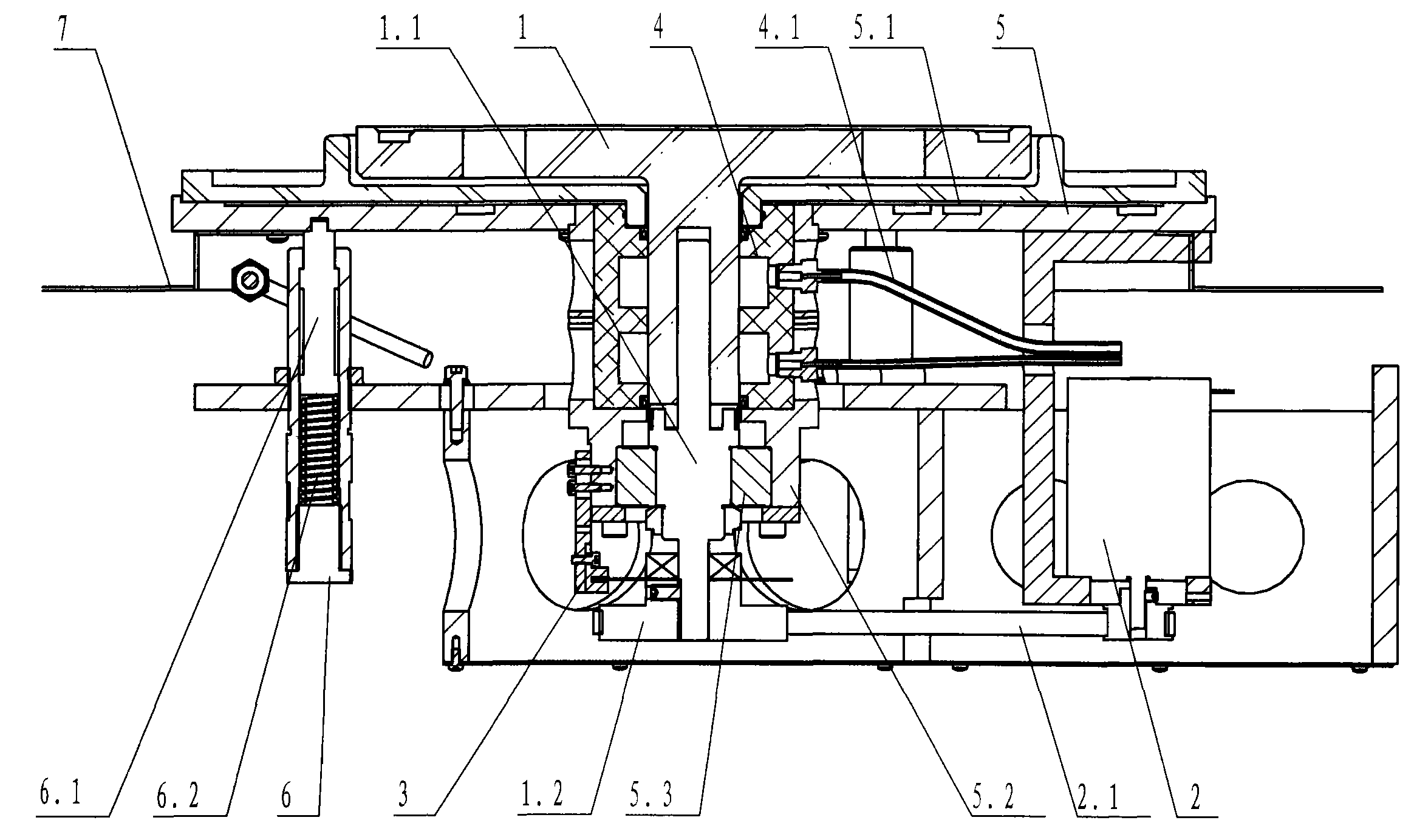

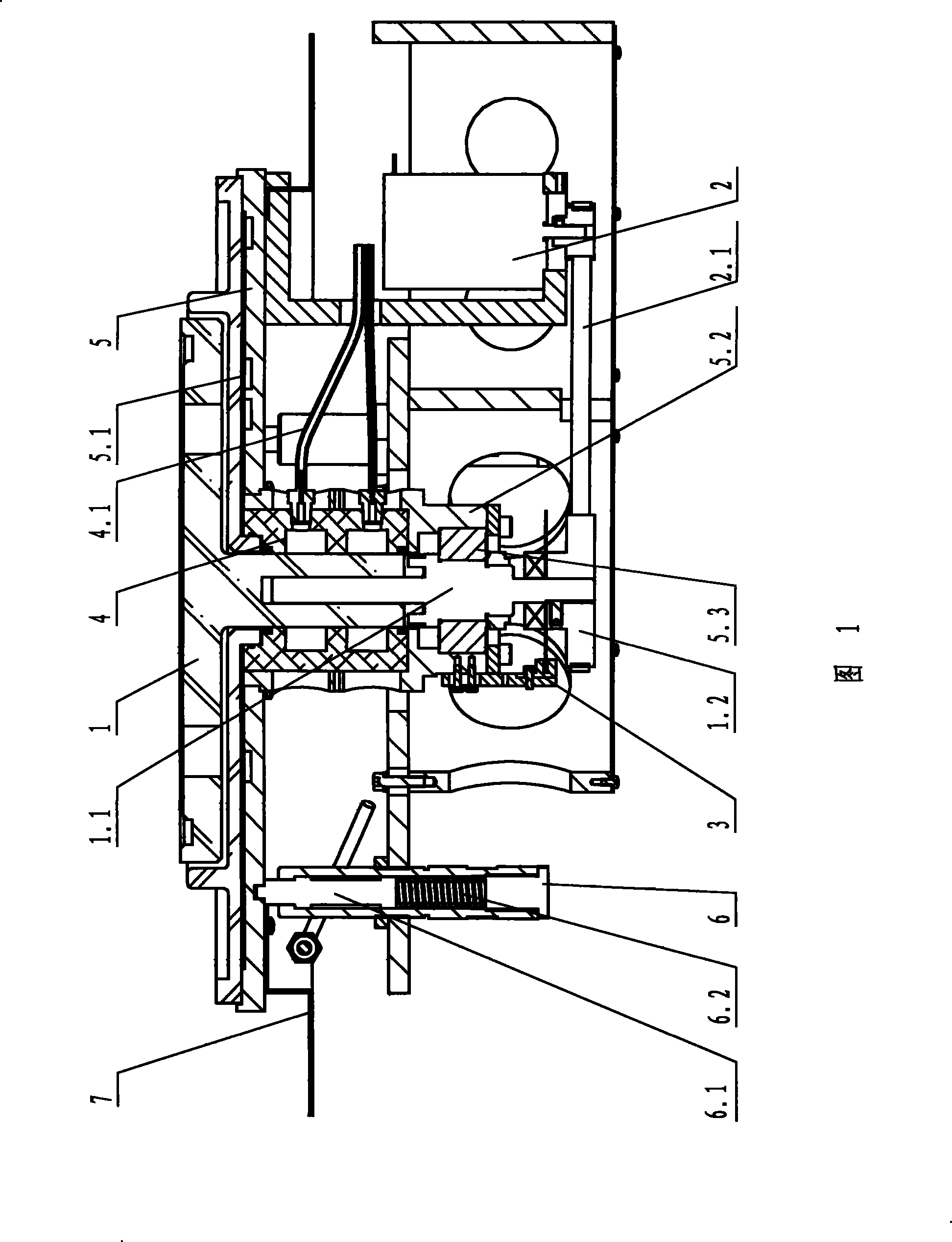

[0007] Below in conjunction with accompanying drawing and embodiment the present invention is further described: embodiment: referring to accompanying drawing, 300mm vertical oxidation furnace quartz boat rotating device is characterized in that: stepping motor 2 is provided, and the bottom of quartz boat is provided with SiC material The finished turntable 1 is provided with a fixed shaft 1.1 at the center of the bottom of the SiC turntable, and a pulley 1.2 is provided at the lower end of the fixed shaft, and the pulley is connected to the stepping motor through a transmission belt 2.1; There is a boat rotating positioning device 3, on the upper part of the fixed shaft, there is a sealed cavity 4 wrapped around the fixed shaft, which is made of polytetrafluoroethylene. A furnace door 5 is provided under the SiC turntable, and a water cooling chamber 5.1 is provided in the furnace door, and a shaft cover 5.2 is fixed at the bottom of the furnace door. A sealing ring 5.3 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com