Glassy composite anode material and preparation method thereof

A negative electrode material and glass state technology, which is applied in the field of glassy composite negative electrode materials and its preparation, can solve the problems of poor cycle performance and achieve the effects of low cost, simple and easy preparation method, and high first-time efficiency

Inactive Publication Date: 2010-08-25

SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to solve the problem of poor cycle performance due to the serious volume effect of silicon negative electrode materials when inserting and removing lithium, and propose a glassy composite negative electrode material and its preparation method by using volume compensation, which can maintain the high silicon density. While maintaining specific capacity characteristics, the volume change of the overall electrode is controlled at a reasonable level, increasing its cycle stability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

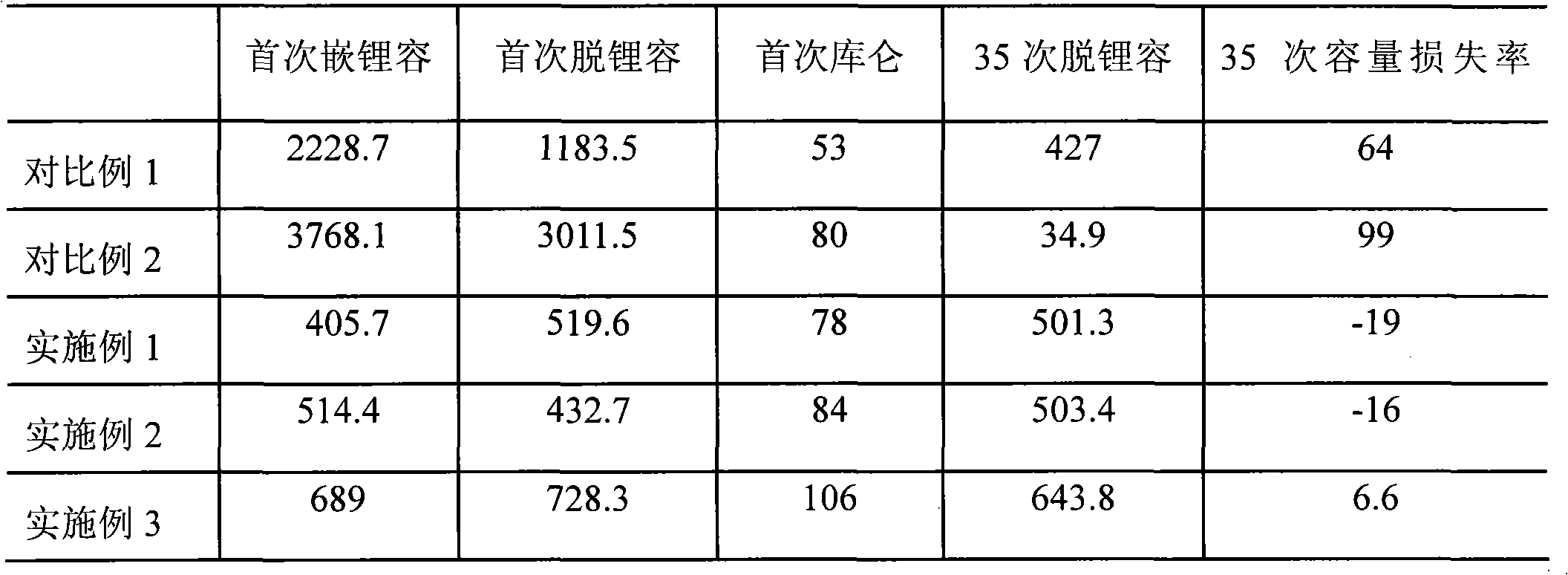

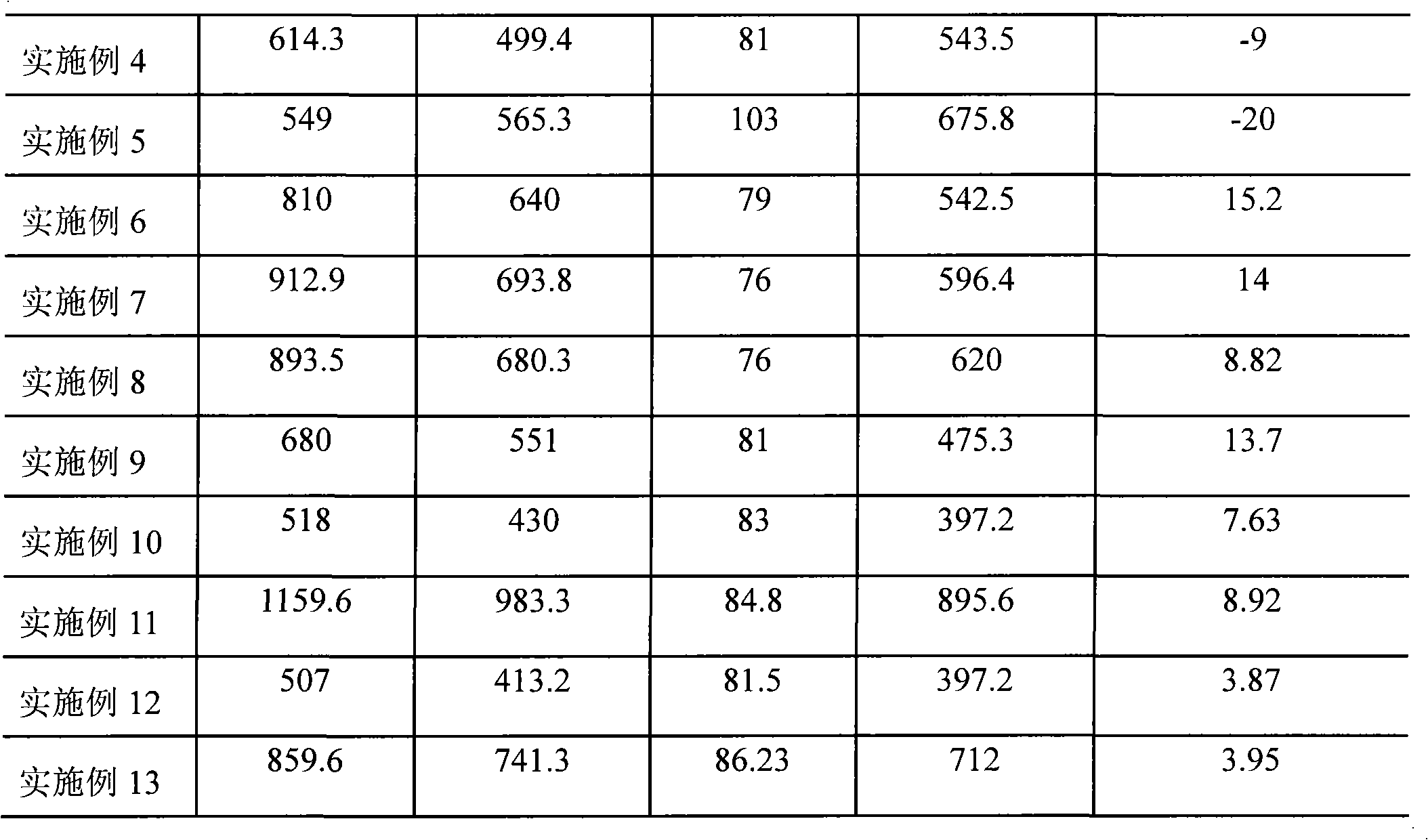

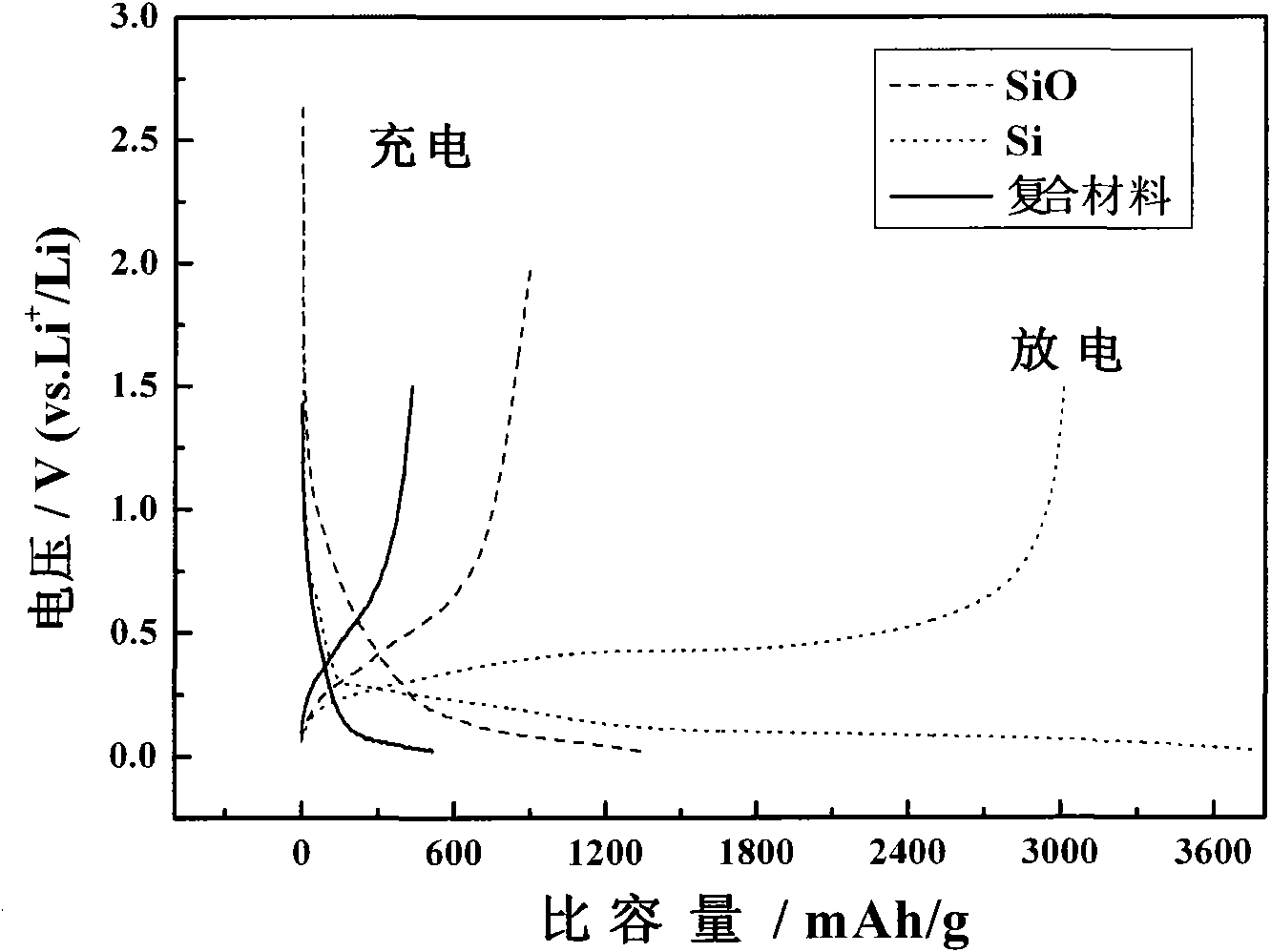

The invention relates to a glassy composite anode material and a preparation method thereof, which belong to the field of eletrochemical power sources. In the invention, a simple substance with the lithium intercalation capacity or an oxide and a suitable reducing agent are adopted to carry out mechanochemical in-situ reduction, and then a glassy oxide and other electric conduction components areadded to be used as dispersing matrixes for further ball milling to prepare the composite material. Aiming at the problem that serious volume effect leads to poor cycle performance in the lithium intercalation and deintercalation process of a silicon anode material, the invention enables the volume change of the overall electrode to be controlled at a reasonable level while keeping the high-specific capacity characteristic so as to improve the cycle stability of the anode material. The first efficiency of the electrode of the composite material is more than 80 percent, and the reversible capacity is larger than 500mAh / g; the composite material has good electrochemical cycle stability.

Description

technical field The invention relates to a glassy composite negative electrode material and a preparation method thereof, belonging to the field of chemical power sources. Background technique Since Sony commercialized lithium-ion batteries in the 1990s, due to its high open circuit voltage, high energy density, long cycle life, no pollution, no memory effect and many other advantages, it has been used in various portable mobile tools and digital products. , artificial satellites, aerospace and many other fields have been widely used; at the same time, it has also set off an upsurge of lithium-ion battery research worldwide. The improvement of lithium-ion battery performance mainly depends on the improvement of energy density and cycle life of electrode materials. At present, graphite and modified graphite are widely used as negative electrode materials in commercial lithium-ion batteries, and the specific capacity is already very close to the theoretical value (372mAh / g), ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M4/36H01M4/38H01M4/42H01M4/48H01M4/50H01M4/58H01M4/04

CPCY02E60/12Y02E60/10

Inventor 温兆银王秀艳刘宇徐小刚吴相伟张敬超韩金铎黄乐之

Owner SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com