A kind of 1000mpa grade low manganese double partition cold-rolled thin steel plate and its preparation method

A technology for cold-rolled steel sheets and thin steel sheets, which is applied in the field of low-manganese double-partition cold-rolled steel sheets, can solve the problems of difficulty in meeting strong plastic levels, no obvious cost advantage, and low strong plastic levels, so as to improve the diffusion activation energy, Improve stability and ensure the effect of high strength and high plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The 1000MPa low-Mn double-partition cold-rolled steel sheet in this embodiment has the following components by mass percentage: C: 0.18%, Si: 0.5%, Mn: 3.5%, Al: 1.5%, V: 0.10%, P: 0.004%, S: 0.003%, N: 0.004%, O: 0.002%, the balance is Fe; the thickness of the steel plate is 1.5mm.

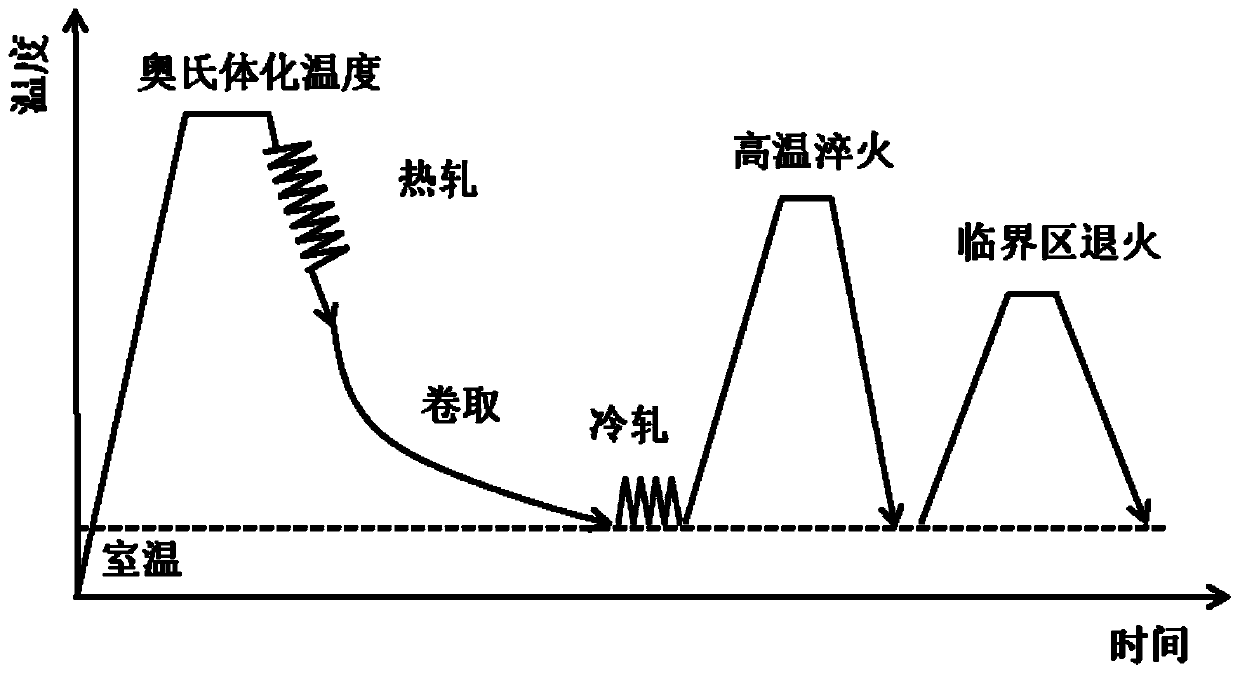

[0038] The method for preparing the 1000MPa-level low-Mn double-partition cold-rolled thin steel sheet in the double critical region by annealing and partitioning in this embodiment includes the following steps:

[0039] 1) Melting is carried out at a temperature of 1580°C according to the composition ratio of a low-Mn double-partition cold-rolled thin steel sheet with a strength-plasticity product of 1000MPa, and then forged to obtain a steel billet with a longitudinal section size of 100mm×100mm;

[0040] 2) The slab is subjected to tissue homogenization treatment, heated to 1180°C, and isothermally held for 2 hours;

[0041] 3) The slab is subjected to multi-pass hot rolling deformatio...

Embodiment 2

[0051] The 1000MPa low-Mn double-partition cold-rolled steel sheet in this embodiment has the following components by mass percentage: C: 0.22%, Si: 0.3%, Mn: 2.5%, Al: 2.0%, V: 0.12%, P: 0.004%, S: 0.003%, N: 0.005%, O: 0.0015%, the balance is Fe; the thickness of the steel plate is 1.2mm.

[0052] The method for preparing the 1000MPa-level low-Mn double-partition cold-rolled thin steel sheet in the double critical region by annealing and partitioning in this embodiment includes the following steps:

[0053] 1) Melting is carried out at a temperature of 1580°C according to the composition ratio of a low-Mn double-partition cold-rolled thin steel sheet with a strength-plasticity product of 1000MPa, and then forged to obtain a steel billet with a longitudinal section size of 100mm×100mm;

[0054] 2) The slab is subjected to tissue homogenization treatment, heated to 1250°C, and isothermally held for 3 hours;

[0055] 3) The slab is subjected to multi-pass hot rolling deformati...

Embodiment 3

[0061] The 1000MPa low-Mn double-partition cold-rolled steel sheet in this embodiment has the following components by mass percentage: C: 0.20%, Si: 0.5%, Mn: 2.8%, Al: 1.4%, V: 0.11%, P: 0.004%, S: 0.003%, N: 0.004%, O: 0.002%, the balance is Fe; the thickness of the steel plate is 1.0 mm.

[0062] The method for preparing the 1000MPa-level low-Mn double-partition cold-rolled thin steel sheet in the double critical region by annealing and partitioning in this embodiment includes the following steps:

[0063] 1) Melting is carried out at a temperature of 1580°C according to the composition ratio of a low-Mn double-partition cold-rolled thin steel sheet with a strength-plasticity product of 1000MPa, and then forged to obtain a steel billet with a longitudinal section size of 100mm×100mm;

[0064] 2) Homogenize the structure of the slab, heat it to 1200°C, and hold it for 2.5 hours;

[0065] 3) The slab is subjected to multi-pass hot rolling deformation in a two-roll mill, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com