Glassy composite anode material and preparation method thereof

A negative electrode material and glass state technology, which is applied in the field of glassy composite negative electrode materials and its preparation, can solve the problems of poor cycle performance and achieve the effects of low cost, simple and easy preparation method, and high first-time efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

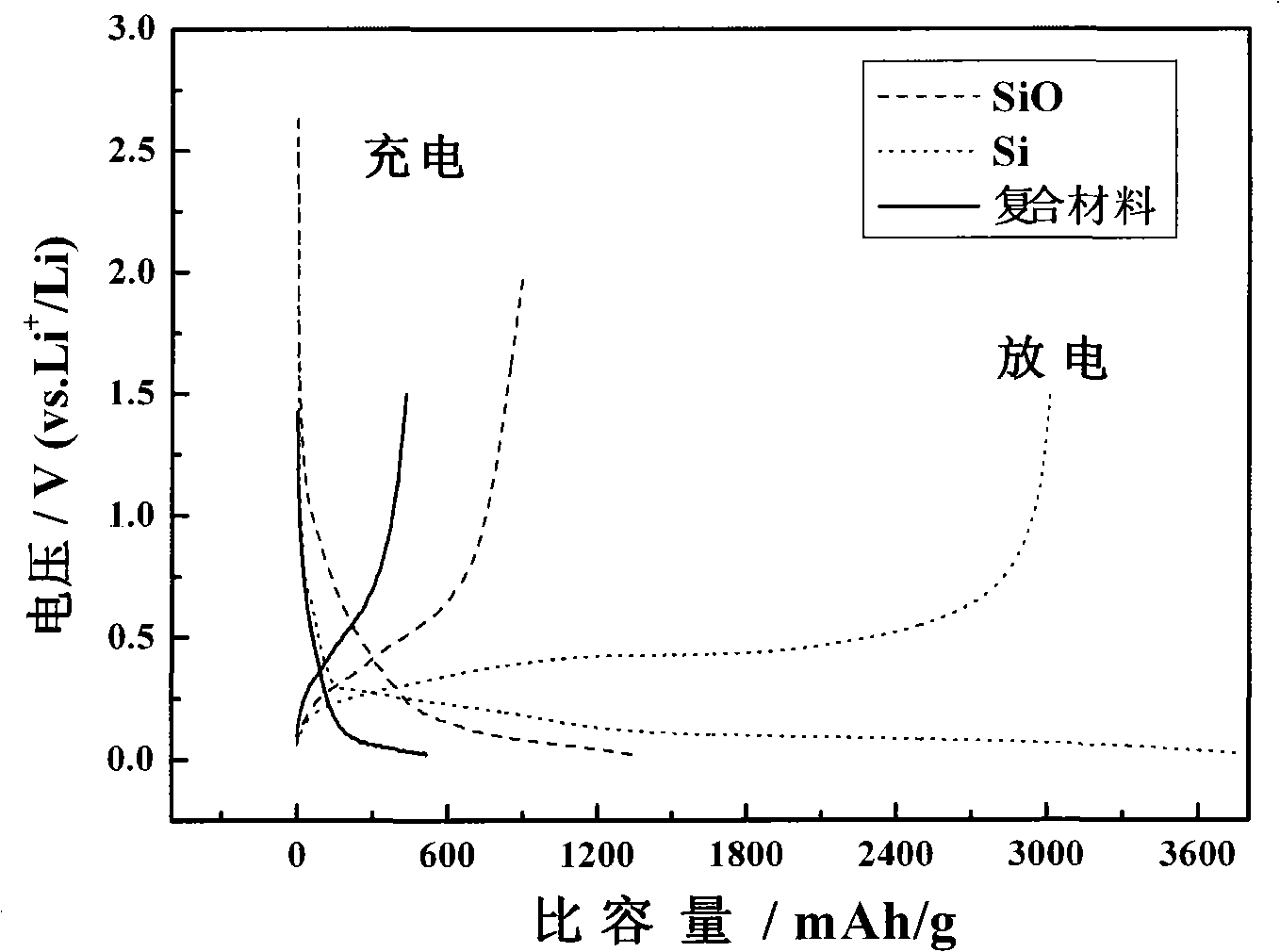

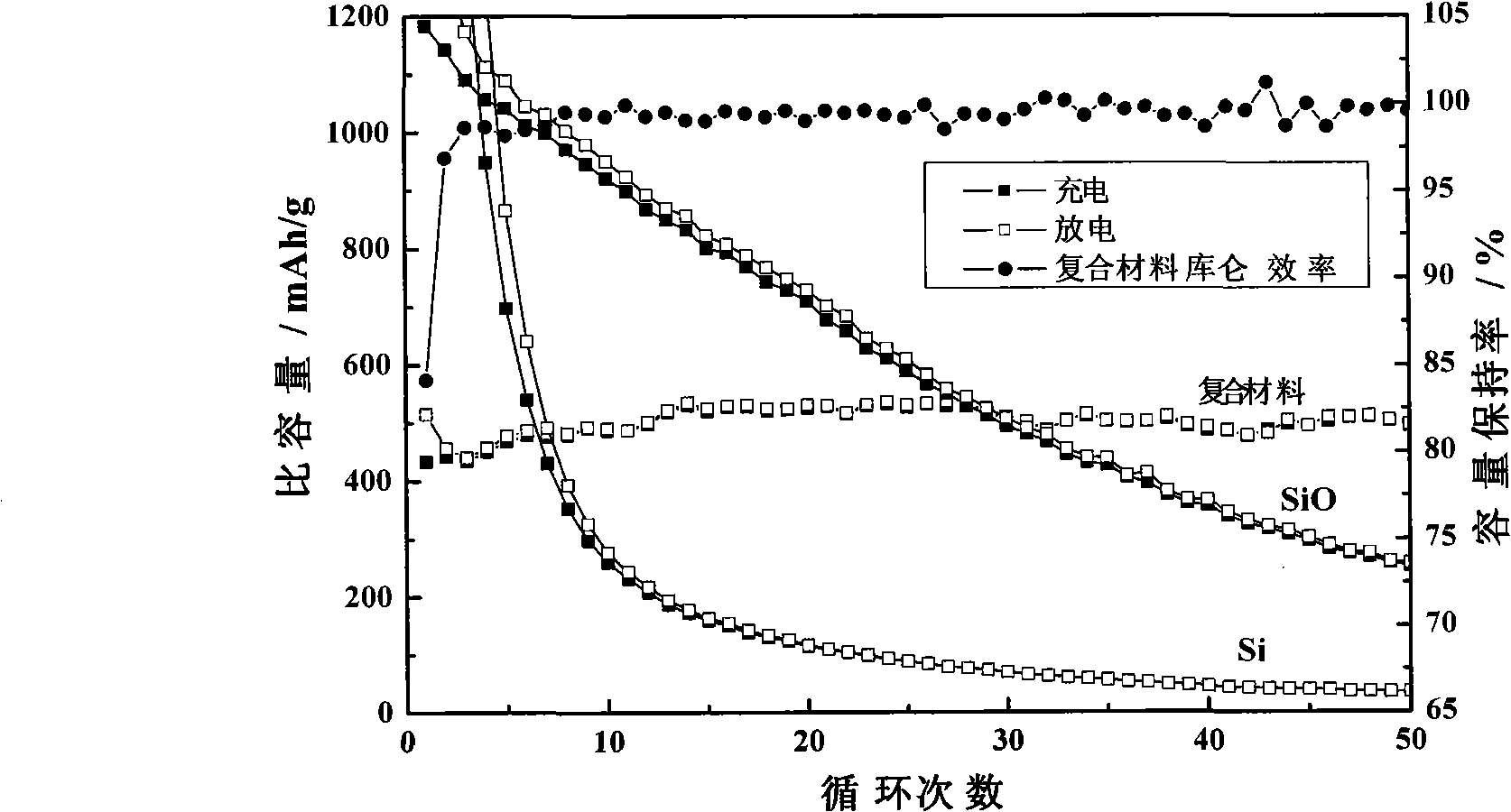

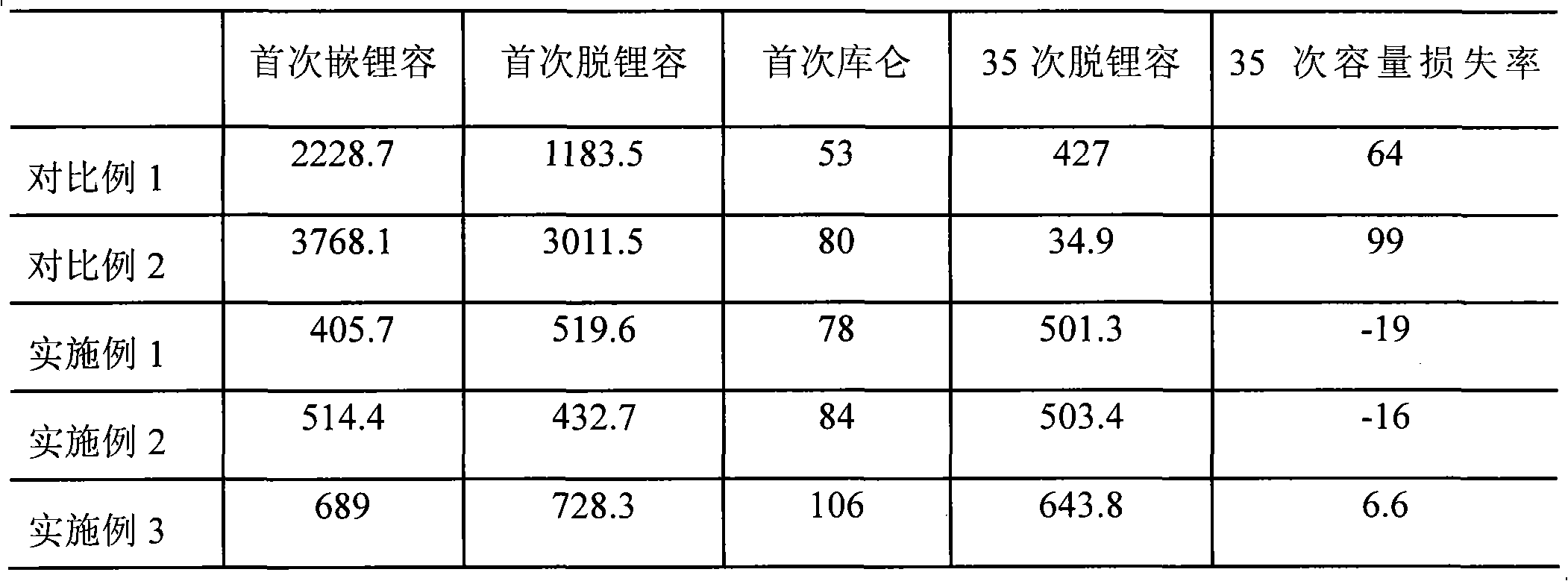

Embodiment 1

[0045] Add 4.8g of SiO, 1.2g of metallic lithium (Si / Li molar ratio of 5:8) and a certain amount of ball milling media into the ball milling tank, high-energy ball milling for 10 hours (under an inert protective atmosphere), and then 7.5wt.% (0.45g) H 3 BO 3 , 7.5wt.% (0.45g) P 2 O 5 And 5wt.% (0.3g) graphite powder are added into the ball mill tank, ball milling is continued for 5 hours, and then the obtained powder is vacuum dried at 100°C for 24 hours to obtain a silicon-based glassy composite material. The electrode preparation method, battery assembly, and test conditions are the same as those in Comparative Example 1. The measurement results are shown in Table 1. From the data in Table 1, it can be seen that compared to pure SiO and Si electrodes, the cycle performance of composite electrodes has been greatly improved.

Embodiment 2

[0047] 4.6g SiO and 1.4g metallic lithium (Si / Li molar ratio is 1:2) and H in the same ratio as in Example 1. 3 BO 3 , P 2 O 5 , Graphite powder according to the method of Example 1 to obtain a silicon-based glassy composite material. The electrode preparation method, battery assembly, and test conditions are the same as those in Comparative Example 1. The test results are shown in Table 1.

Embodiment 3

[0049] 4.6g SiO and 1.4g metal lithium (Si / Li molar ratio is 1:2) and 2.5wt.%B 2 O 3 (0.15g), 2.5wt.%(0.15g)P 2 O 5 , 5wt.% (0.3g) graphite powder according to the method of Example 1 to obtain a silicon-based glassy composite material. The electrode preparation method, battery assembly, and test conditions are the same as those in Comparative Example 1. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com