Metal-organic compound silicon alloy negative electrode material and preparation method thereof

A metal-organic and anode material technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of insufficient utilization of metals and carbon and nitrogen elements, and achieve mild reaction conditions, easy availability of materials, and good cycle performance. Excellent rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

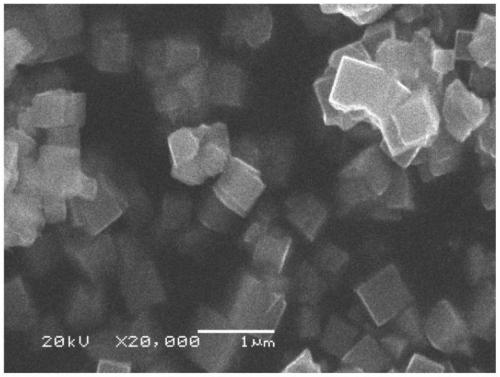

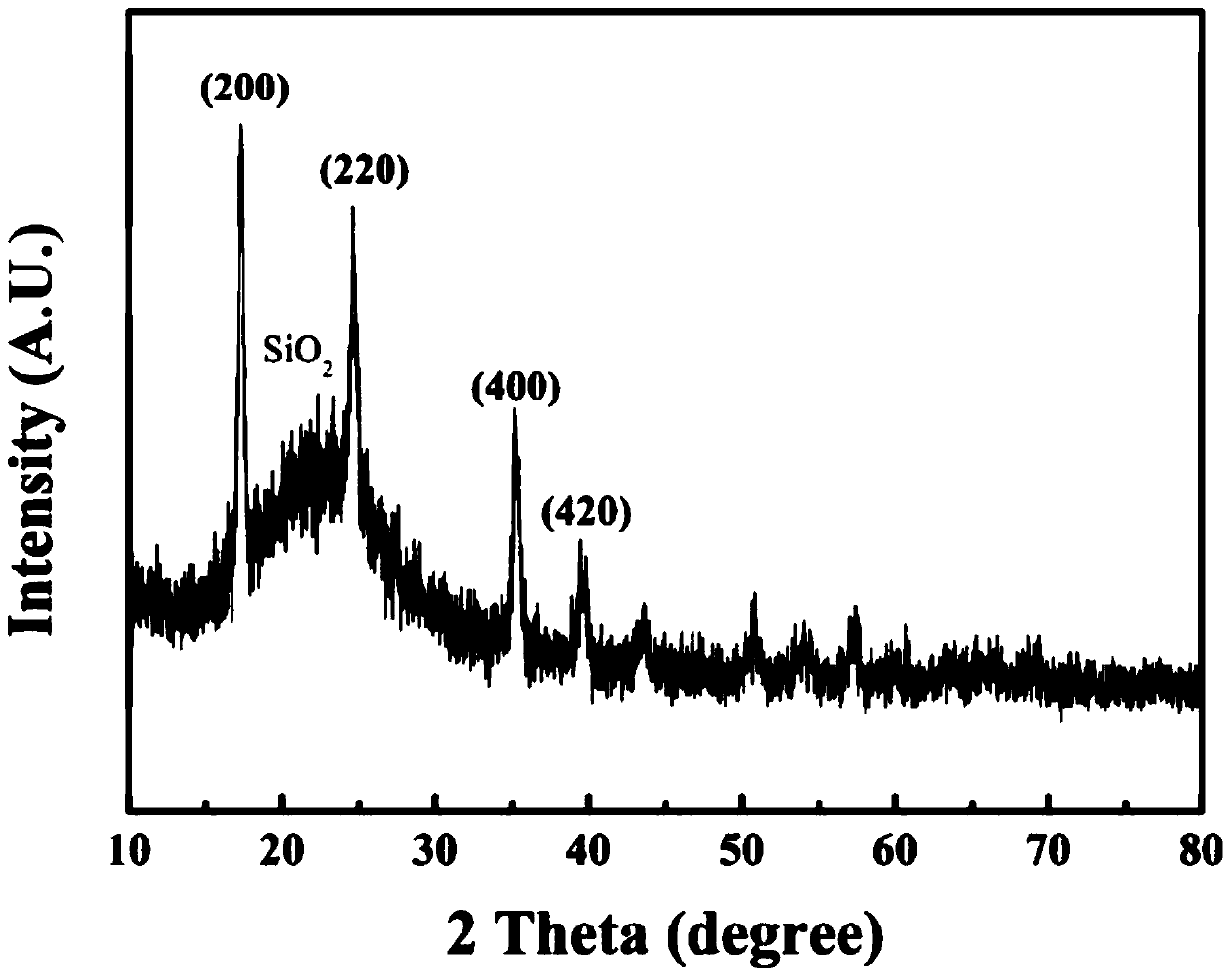

[0058] At room temperature, uniformly disperse 1 g of nickel ferricyanide nanoparticles into a mixed solution of 200 mL of ethanol and 300 mL of deionized water, add 30 mL of concentrated ammonia, and stir and disperse for 0.5 h, which is recorded as A solution.

[0059] Dissolve 8 mL of ethyl orthosilicate in 500 mL of ethanol and quickly add the A solution, stir quickly at 1200 rpm for 3 min, and then slowly stir at 350 rpm for 2 h. The obtained materials were separated by centrifugation at 9000 rpm for 5 minutes, washed with 100 mL of deionized water and ethanol, and dried in an oven at 80°C for 4 hours. Take the obtained material, magnesium powder and sodium chloride at a mass ratio of 1:0.8:10, mix and grind uniformly, place them in a closed metal container and transfer them into an argon tube furnace. The tube furnace is heated at 2°C / min to 650°C Keep at constant temperature for 5h, then cool down naturally. The obtained material was immersed in 5% hydrochloric acid for 1...

Embodiment 2

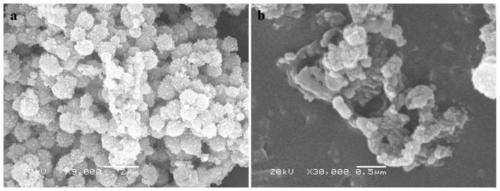

[0065] At room temperature, 1 g of iron ferricyanide nanoparticles were uniformly dispersed into a mixed solution of 200 mL of ethanol and 300 mL of deionized water, 50 mL of concentrated ammonia was added, and the mixture was stirred and dispersed for 2 hours, which was recorded as A solution.

[0066] Dissolve 5 mL of ethyl orthosilicate in 500 mL of ethanol and quickly add solution A, stir quickly at 800 rpm for 3 minutes, and then slowly stir at 200 rpm for 2 hours. The obtained materials were separated by centrifugation at 9000 rpm for 5 minutes, washed with 100 mL of deionized water and ethanol, and dried in an oven at 80°C for 4 hours. Take the obtained material, magnesium powder and sodium chloride at a mass ratio of 1:0.2:10, mix and grind uniformly, place them in a closed metal container and transfer them into an argon furnace tube furnace. The tube furnace is heated to 10℃ / min. Keep the temperature at 700°C for 5h, then cool down naturally. The obtained material was i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com