Preparation method of lithium-ion battery anode material that effectively buffers silicon volume effect

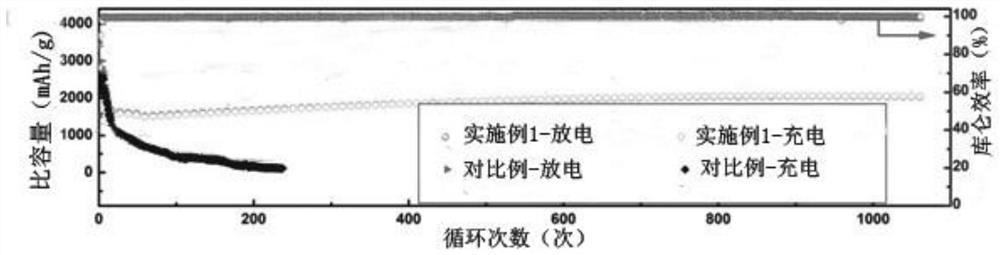

A lithium-ion battery, volume effect technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve problems such as unsatisfactory cycle life, nano-silicon-based material preparation technology needs to be improved, etc. Achieve excellent long-term cycle stability and rate performance, increase electron and ion transmission efficiency, and buffer volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

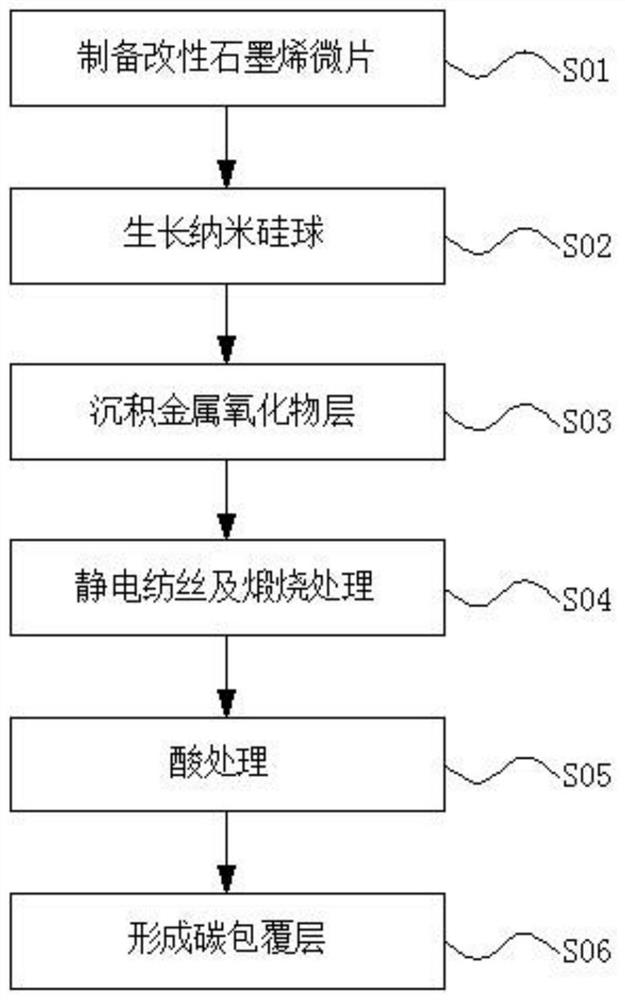

[0023] Such as figure 1 Shown, the preparation method of the negative electrode material of the lithium ion battery of effectively buffering silicon volume effect, described method comprises the following steps:

[0024] S01, preparing modified graphene microchips;

[0025] S02, growing nano-silicon spheres on the surface of the graphene micro-sheets to obtain a graphene micro-sheet-nano-silicon sphere composite material;

[0026] S03. Depositing a metal oxide layer with a precise thickness on the surface of graphene microflakes-nano-silicon spheres by atomic layer deposition technology;

[0027] S04, uniformly dispersing the graphene microchip-nano-silicon sphere composite material with a metal oxide layer deposited on the surface into the electrospinning solution, performing electrospinning and calcination treatment, to obtain a carbon nanofiber composite material;

[0028] S05. Carry out acid treatment to the carbon nanofiber composite material, completely remove the meta...

Embodiment 1

[0034]First, put the expanded graphite in a container, add 250ml of NMP, stir evenly, and oscillate for 10 hours at an ultrasonic oscillation power of 800W and a temperature of 75°C to obtain a suspension of graphene microflakes; then let it stand for 180 minutes, and take the upper suspension , remove the precipitate, filter and dry at 70°C to obtain graphene microflakes; then add the obtained graphene microflakes to 80ml of concentrated sulfuric acid, keep the solution temperature below 4°C, and slowly add 1g of potassium permanganate , keep the temperature of the solution below 10°C and stir magnetically for 90min, at the same time, slowly add 150ml of deionized water during the magnetic stirring process; add 3ml of hydrogen peroxide after stirring, and continue stirring for 20min; finally filter and dry to obtain surface modified graphite ene microchips;

[0035] Then put the obtained graphene microchips into the chemical vapor deposition (CVD) reaction chamber, vacuumize ...

Embodiment 2

[0039] First, put the expanded graphite in a container, add 150ml of DMF, stir evenly, and oscillate for 8 hours under the conditions of ultrasonic oscillation power of 1000W and temperature of 80°C to obtain a suspension of graphene microflakes; then stand still for 180min, and take the upper suspension , remove the precipitate, filter and dry at 70°C to obtain graphene microflakes; then add the obtained graphene microflakes to 100ml of concentrated sulfuric acid, keep the solution temperature below 4°C, and slowly add 0.5 potassium permanganate , keep the temperature of the solution below 10°C and stir it magnetically for 120min. During the process of magnetic stirring, slowly add 150ml of deionized water; after stirring, add 3ml of hydrogen peroxide, and continue stirring for 30min; finally filter and dry to obtain surface-modified graphite ene microchips;

[0040] Then put the obtained graphene microchips into the chemical vapor deposition (CVD) reaction chamber, vacuumize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com