Integrated lithium ion battery and preparation method thereof

A lithium-ion battery and electrode sheet technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as damage, structural failure, interface relaxation, etc., and achieve improved adhesion, low roughness, and roughness. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

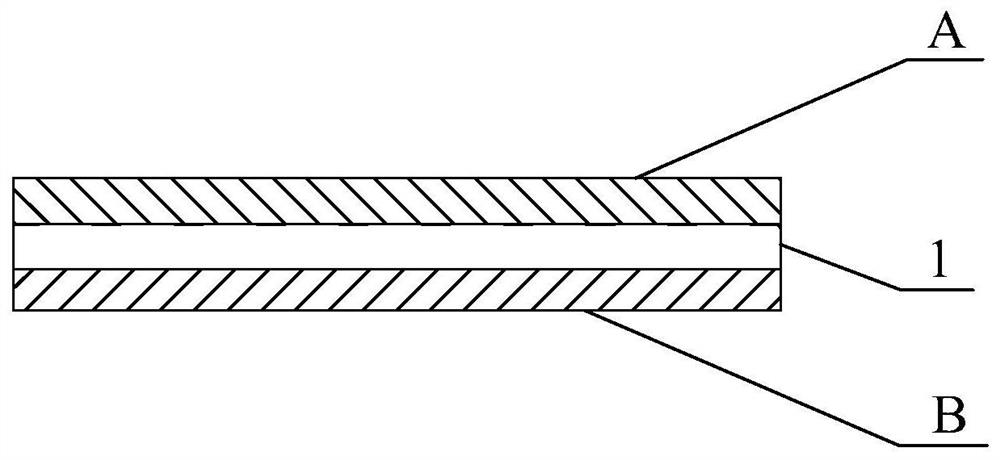

[0036] Such as figure 1 As shown, the Janus diaphragm is composed of polyimide high-temperature resistant support layer 1 and polyacrylic acid polar functional layer A and polytetrafluoroethylene-hexafluoropropylene non-polar functional layer B loaded on both sides of the high-temperature resistant support layer; the The thickness of the Janus separator is 18 μm, the porosity is 45.7%, the heat shrinkage rate is 0.0% (150°C, 2h), the surface energy of the polar functional layer is 45.8mN / m, and the surface energy of the non-polar functional layer is 16.3mN / m;

[0037] (1) Activate the A side of the Janus diaphragm at 55°C in ozone;

[0038] (2) Activate the B side of the Janus diaphragm at 35°C in N,N-dimethylformamide;

[0039] (3) Heat the Janus diaphragm and the positive and negative electrode sheets after steps (1) and (2) according to [negative electrode sheet / A-B / positive electrode sheet / B-A] or [B-A / negative electrode sheet / A-B / positive electrode sheet] The structural...

Embodiment 2

[0042] Such as figure 1 As shown, the Janus diaphragm is composed of titanium oxide high-temperature resistant support layer 1 and polyethylene oxide polar functional layer A and polytetrafluoroethylene non-polar functional layer B loaded on both sides of the high-temperature resistant support layer; the Janus diaphragm thickness 5μm, porosity 25%, thermal shrinkage rate 0.5% (150°C, 2h), surface energy of polar functional layer is 60.5mN / m, surface energy of non-polar functional layer is 15.8mN / m;

[0043] (1) Activate the A side of the Janus diaphragm at 45°C in nitric acid containing 5wt% ammonia;

[0044] (2) Activate the B side of the Janus diaphragm at 10°C in ethanol;

[0045] (3) Heat the Janus diaphragm and the positive and negative electrode sheets after steps (1) and (2) according to [negative electrode sheet / A-B / positive electrode sheet / B-A] or [B-A / negative electrode sheet / A-B / positive electrode sheet] The structural unit is obtained by pressing and combining. D...

Embodiment 3

[0048] Such as figure 1 As shown, the Janus diaphragm is composed of polyether ether ketone high temperature resistant support layer 1 and polypropylene oxide polar functional layer A and graphene nonpolar functional layer B loaded on both sides of the high temperature resistant support layer; the thickness of the Janus diaphragm is 50 μm, porosity 65%, thermal shrinkage rate 0.2% (150°C, 2h), the surface energy of the polar functional layer is 55.6mN / m, and the surface energy of the non-polar functional layer is 13.8mN / m;

[0049] (1) Activate the A side of the Janus diaphragm at 85°C in sodium perchlorate;

[0050] (2) Activate the B side of the Janus diaphragm at 45°C in N-methylpyrrolidone;

[0051] (3) Heat the Janus diaphragm and the positive and negative electrode sheets after steps (1) and (2) according to [negative electrode sheet / A-B / positive electrode sheet / B-A] or [B-A / negative electrode sheet / A-B / positive electrode sheet] The structural unit was obtained by pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com