Mn-TRIP steel plate with product of strength and elongation of 50 GPa% for automobile and preparation method of Mn-TRIP steel plate

A technology of strong plastic products and steel plates, which is applied in the direction of improving process efficiency and can solve the problems of increasing the cost of material alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

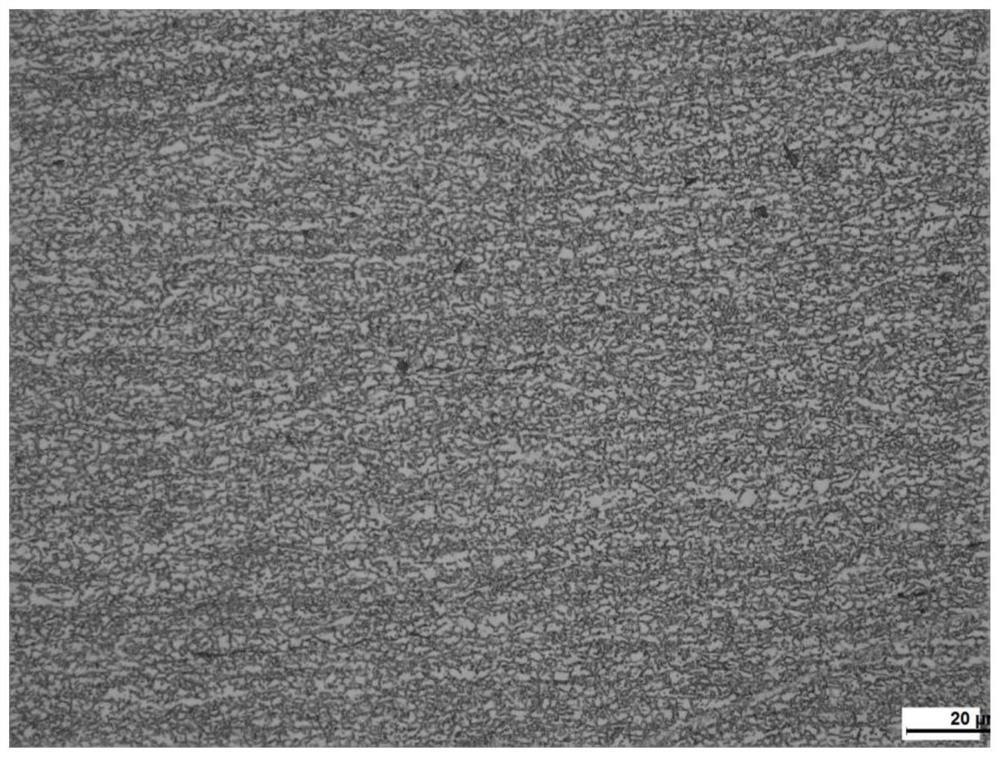

Image

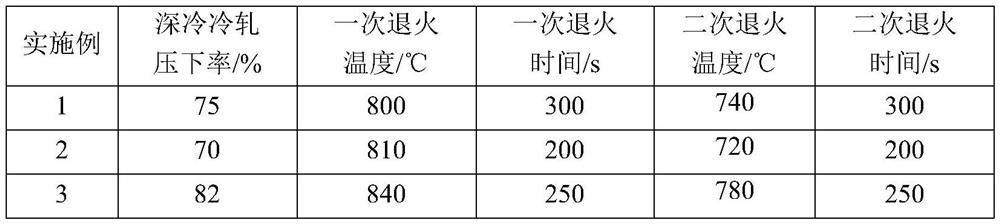

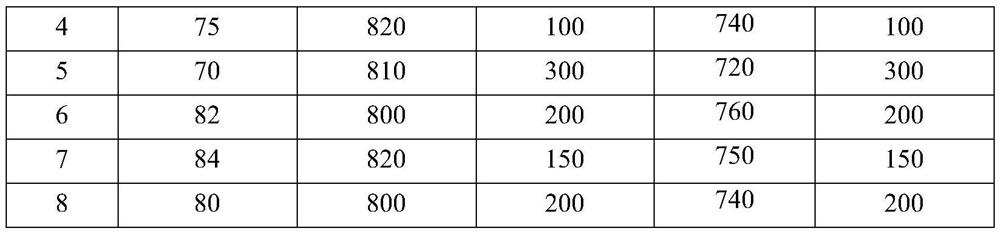

Examples

preparation example Construction

[0027] A kind of preparation method of Mn-TRIP steel plate for automobile with strong plasticity 50GPa%, specifically comprises the following steps:

[0028] 1) Smelting molten steel according to chemical composition requirements, and casting it into slabs;

[0029] 2) Homogenize the structure of the slab, heat it to 1200-1250°C, and hold it for 2-3 hours;

[0030] 3) The slab is subjected to multi-pass hot rolling deformation, the starting rolling temperature is 1150-1180°C, and the final rolling temperature is 900-950°C; the reduction rate of each pass is not less than 30%, and the cumulative reduction rate is ≥95%; after rolling Wait until the temperature reaches 680~750℃ for coiling;

[0031] 4) The hot-rolled and pickled steel plate is subjected to cryogenic rolling treatment. Specifically, the hot-rolled steel plate is soaked in liquid nitrogen for more than 30 minutes to ensure that the temperature of the steel plate is below -196°C; then the steel plate is taken out a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strong plastic product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com