Method for preparing imporous carbon absorbent material

A technology of adsorption materials and porous carbon, applied in chemical instruments and methods, and other chemical processes, can solve the problems of limited application of activated carbon, limited source of single carbon source, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

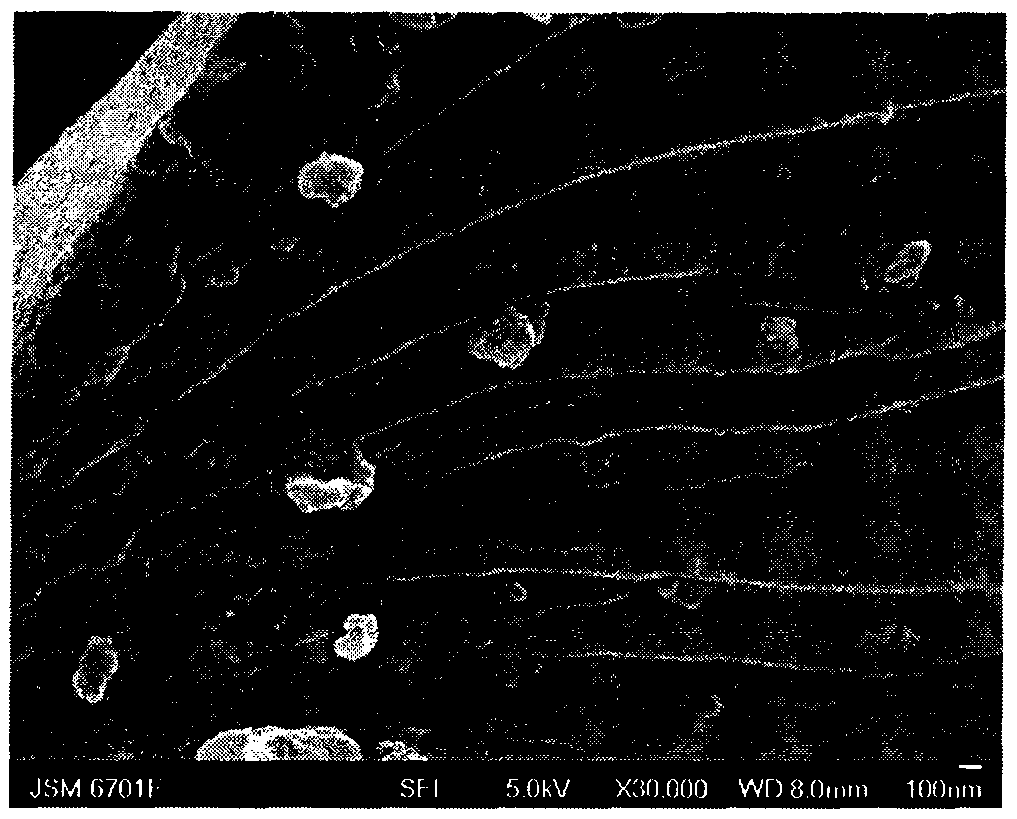

Image

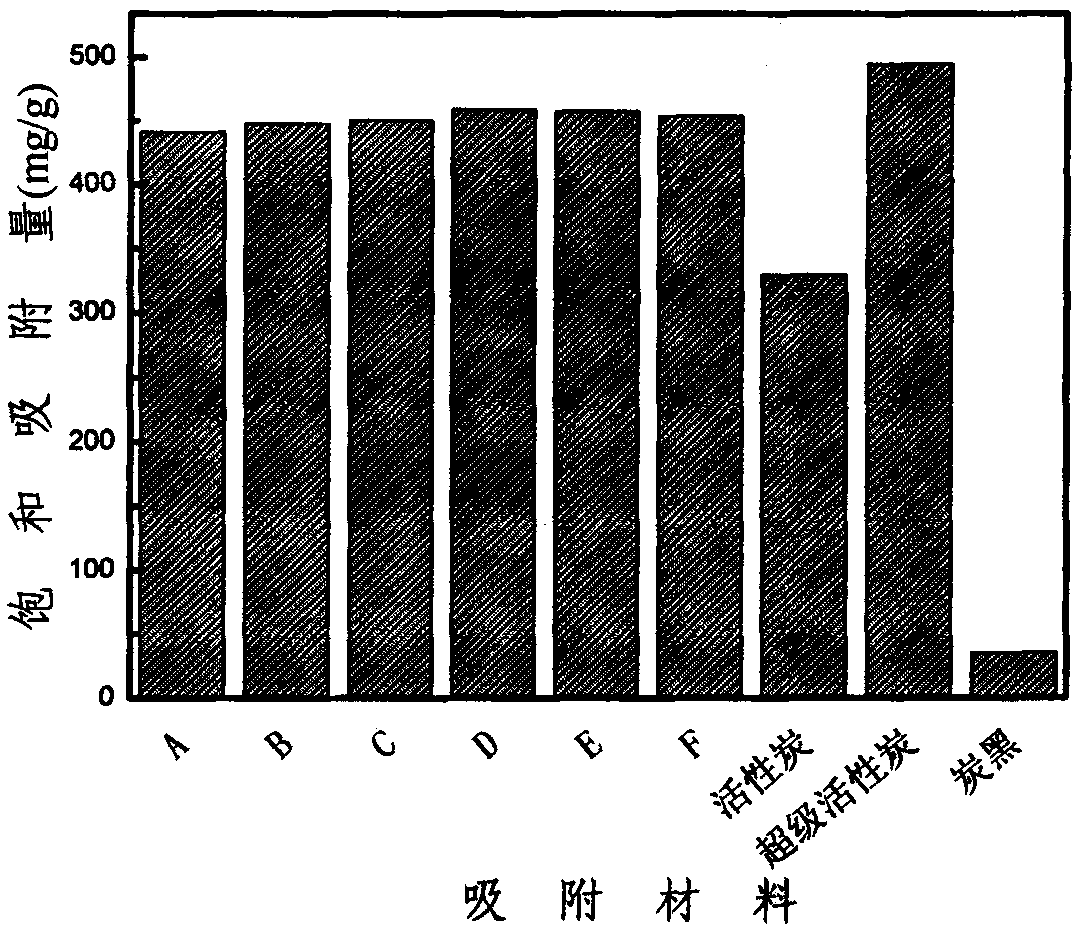

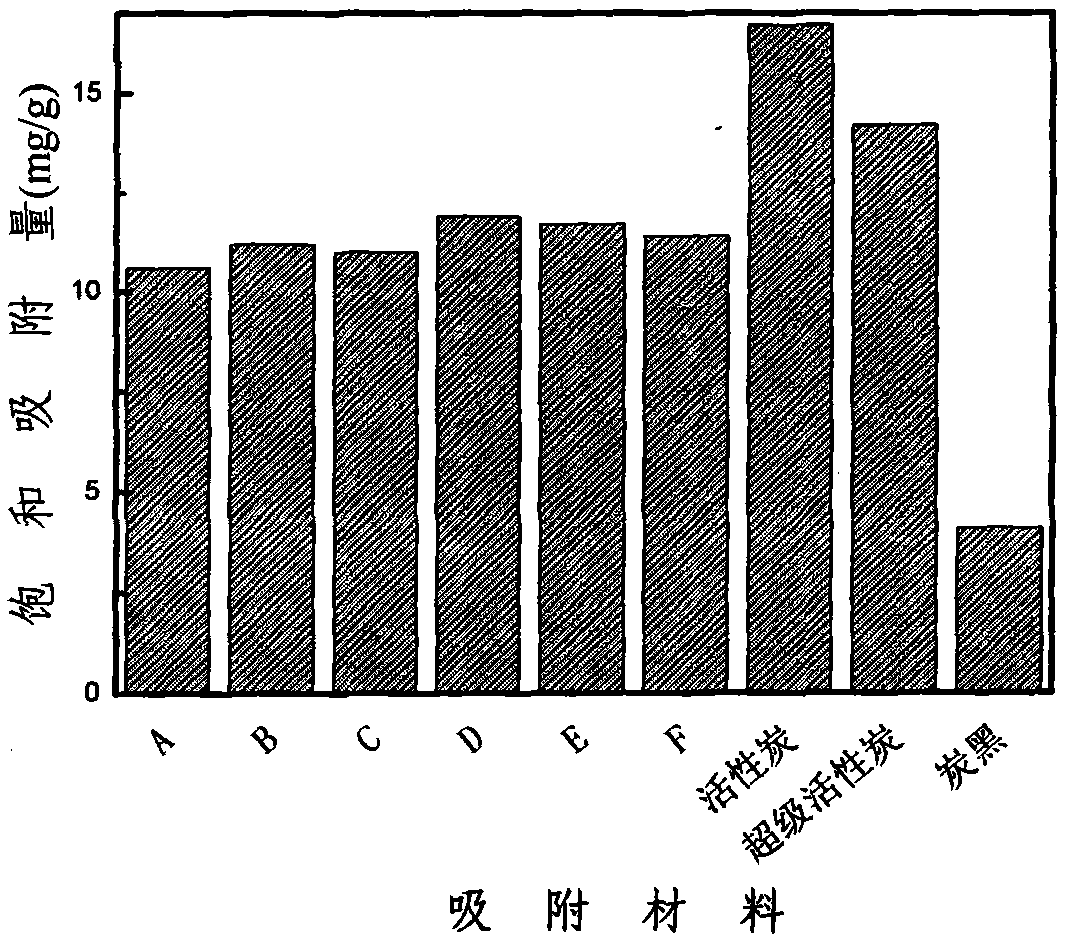

Examples

Embodiment 1

[0016] Take sucrose, add 98% sulfuric acid at a mass ratio of 1:2, stir evenly, pre-oxidize to bread shape at 150°C, and oxidize for 4 hours at a vacuum degree of 0.08Mpa and a temperature of 220°C, and use 3M sodium hydroxide solution to generate waste gas during the oxidation process absorption, vacuum cooling to room temperature under a vacuum degree of 0.08MPa, and grinding to obtain a new type of non-porous carbonaceous adsorption material, denoted as A.

Embodiment 2

[0018] Take sucrose, add 98% sulfuric acid at a mass ratio of 1:2.5, stir evenly, pre-oxidize to bread shape at 160°C, oxidize at 220°C, vacuum degree 0.07MPa for 4.5 hours, and oxidize waste gas with 4M sodium carbonate and 3M hydroxide during the oxidation process Potassium mixed solution absorption, vacuum cooling to room temperature under vacuum degree of 0.08MPa, grinding, that is to obtain a new type of non-porous carbonaceous adsorption material, denoted as B.

Embodiment 3

[0020] Take sucrose, add 98% sulfuric acid at a mass ratio of 1:2.5, stir evenly, pre-oxidize to bread shape at 170°C, oxidize at 230°C, vacuum degree 0.07MPa for 4.5 hours, use 4M sodium hydroxide and 6M carbonic acid to generate waste gas during the oxidation process Sodium mixed solution absorption, vacuum cooling to room temperature under vacuum degree of 0.07MPa, grinding to obtain a new type of non-porous carbonaceous adsorption material, denoted as C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com