Preparation method of sludge conditioner

A technology for sludge conditioning and preparation steps, which is applied in the field of sludge conditioner preparation, which can solve the problems of monomeric acrylamide toxicity and poor degradation, and achieve good water solubility, strong adsorption performance, and increase the relative molecular weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

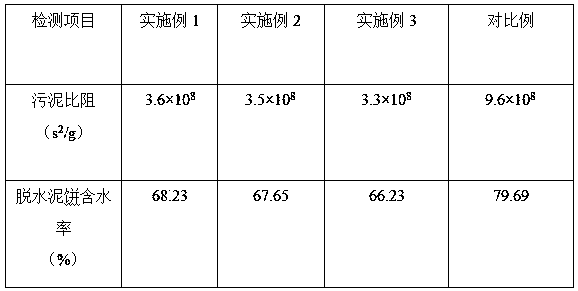

Embodiment 1

[0029] Mix sulfonated lignin and 20% sodium hydroxide solution at a mass ratio of 1:5, and disperse ultrasonically for 5 minutes to obtain a mixed solution. Centrifuge the mixed solution at a speed of 3000 r / min for 20 minutes, and collect the supernatant. Use a 10% hydrochloric acid solution to adjust the pH of the supernatant to 2, and heat it at 90°C for 40 minutes to obtain the matrix liquid. After the matrix liquid is allowed to stand for 6 hours, suction filter to obtain the filter residue. Wash the filter residue with ion water until it is neutral, place it in an oven at 50°C, dry it to constant weight, and cool it to room temperature to obtain the pretreated lignin; weigh 1 part of pretreated lignin, 1 part of sodium thiosulfate, 5 parts of acrylic acid, 1 part of potassium persulfate, 90 parts of mass fraction are 25% sodium hydroxide solution, the pretreated lignin and mass fraction are mixed with 25% sodium hydroxide solution, and the stirring speed is Stir at 300r / ...

Embodiment 2

[0031] Mix sulfonated lignin and 20% sodium hydroxide solution at a mass ratio of 1:5, disperse ultrasonically for 7 minutes to obtain a mixed solution, centrifuge the mixed solution at a speed of 3500 r / min for 25 minutes, and collect the supernatant. Use a 10% hydrochloric acid solution to adjust the pH of the supernatant to 2.5, and heat it at 95°C for 50 minutes to obtain the matrix liquid. After standing the matrix liquid for 7 hours, suction filter to obtain the filter residue. Wash the filter residue with ion water until neutral, dry it in an oven at 55°C to constant weight, and cool to room temperature to obtain pretreated lignin; weigh 5 parts of pretreated lignin, 2 parts of sodium thiosulfate, 10 parts of acrylic acid, 2 parts of potassium persulfate, 95 parts of mass fraction are 25% sodium hydroxide solution, the pretreated lignin and mass fraction are mixed with 25% sodium hydroxide solution, and the stirring speed is Stir at 350r / min for 13min to obtain the reac...

Embodiment 3

[0033] Mix sulfonated lignin and 20% sodium hydroxide solution at a mass ratio of 1:5, and disperse ultrasonically for 10 minutes to obtain a mixed solution. Centrifuge the mixed solution at a speed of 4000 r / min for 30 minutes, and collect the supernatant. Use a 10% hydrochloric acid solution to adjust the pH of the supernatant to 3, and heat it at 100°C for 60 minutes to obtain the matrix liquid. After standing the matrix liquid for 8 hours, suction filter to obtain the filter residue. Wash the filter residue with ion water until neutral, dry it in an oven at 60°C to constant weight, and cool to room temperature to obtain pretreated lignin; weigh 10 parts of pretreated lignin, 3 parts of sodium thiosulfate, 15 parts of acrylic acid, 3 parts of potassium persulfate, 100 parts of mass fraction are 25% sodium hydroxide solution, the pretreated lignin and mass fraction are mixed with 25% sodium hydroxide solution, and the stirring speed is Stir at 400r / min for 15min to obtain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com