Synthesis method of ordered super-micropore material with broad bean shape

A synthesis method and ultra-microporous technology, which is applied in chemical instruments and methods, molecular sieve compounds, molecular sieves and alkali exchange compounds, etc., can solve the loss of further modulation of material morphology, lack of systematic research, depth, and poor correlation, etc. problem, to achieve the effect of rigid and stable shape, simple reaction system and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

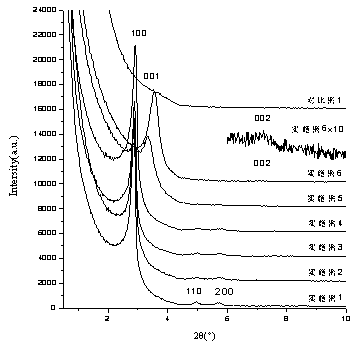

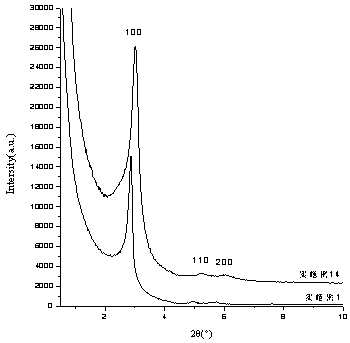

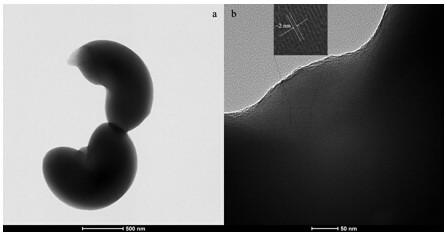

Embodiment 1

[0023] At 35°C, the template agent dehydroabietyltrimethylammonium bromide (DTAB) and methylamine were dissolved in deionized water, and tetraethyl orthosilicate (TEOS) was added under stirring conditions. The moles of the above raw materials than TEOS ׃DTAB ׃methylamine ׃H 2 O=1.0׃0.15׃2.68׃699.06, continue to stir for 30 s, put it into a hydrothermal reaction kettle after standing for 24 h, crystallize at 100 °C for 12 h, wash and filter and dry in an oven at 100 °C for 6 h, Obtain silicon dioxide precursor powder.

Embodiment 2

[0025] At 30°C, the template agent dehydroabietyltrimethylammonium bromide (DTAB) and ethylamine were dissolved in deionized water, and tetraethyl orthosilicate (TEOS) was added under the condition of stirring. than TEOS ׃DTAB ׃ethylamine ׃H 2 O=1.0׃0.15׃2.68׃699.06, continue to stir for 30s, put it into a hydrothermal reaction kettle after standing for 24h, crystallize at 100°C for 24h, wash and filter and dry in an oven at 95°C for 6h to obtain Silicon precursor powder.

Embodiment 3

[0027] At 38°C, the template agent dehydroabietyltrimethylammonium bromide (DTAB) and propylamine were dissolved in deionized water, and tetraethyl orthosilicate (TEOS) was added under stirring conditions. The molar ratio of the above raw materials for TEOS ׃DTAB ׃ propylamine ׃H 2 O=1.0׃0.15׃2.68׃699.06, continue to stir for 30s, put it into a hydrothermal reaction kettle after standing and aging for 24h, crystallize at 100°C for 48h, wash and filter and dry in an oven at 100°C for 5h to obtain carbon dioxide Silicon precursor powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com