A kind of synthetic method of ordered ultramicroporous silica

A silicon dioxide and synthesis method technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems that are not suitable for large-scale industrial production and application, harsh reaction conditions, complex production process, etc., and achieve stable shape and low price. Effect of low cost and simple reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

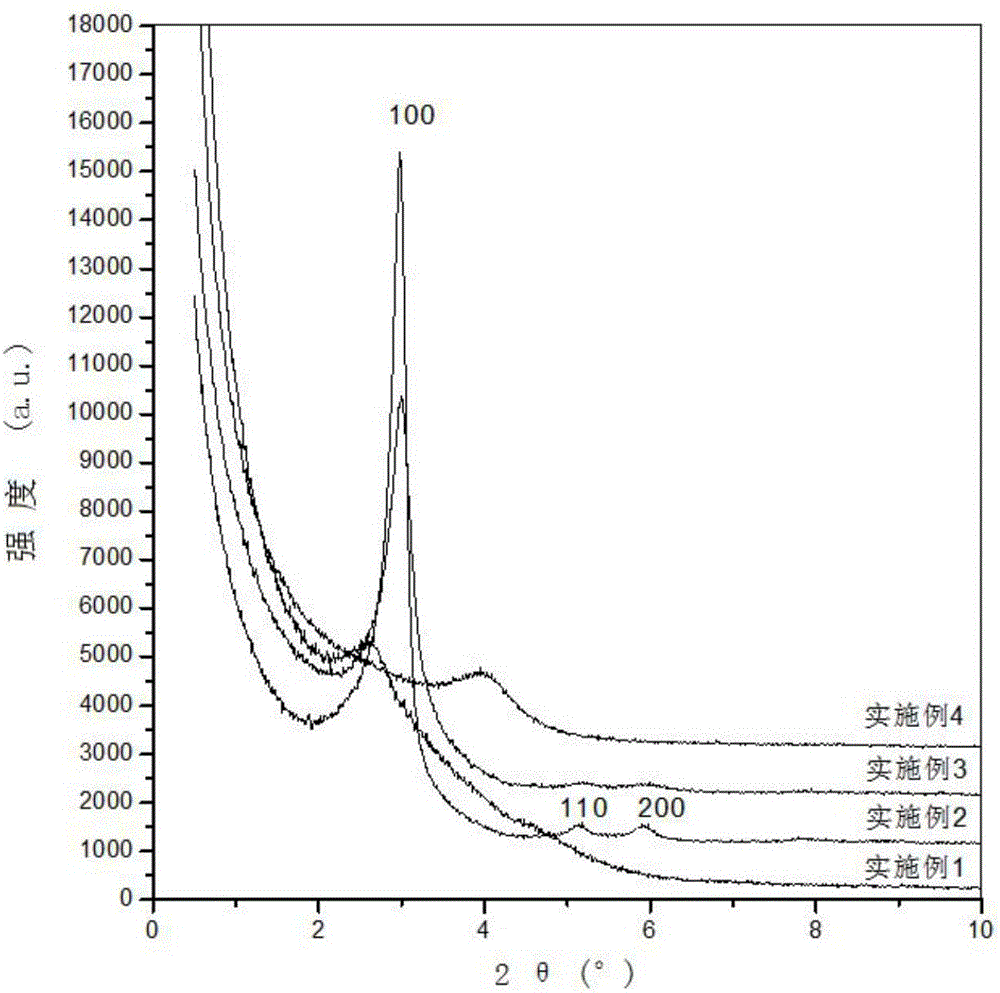

[0022] A kind of synthetic step of ordered ultramicroporous silica is as follows: at the temperature of 35 DEG C, sodium silicate and hydroabietyltrimethylammonium bromide (DTAB) are dissolved in deionized water, under the condition of stirring Slowly add inorganic acid dropwise until the pH of the solution is 8-10, and the ratio of material to SiO 2 :DTAB:HCl:H 2 O=1.0: 0.2: (1.4~2.1): 808.0, wherein the amount of HCl added is 2.1 in Example 1, 1.9 in Example 2, 1.7 in Example 3, and 1.4 in Example 2. After continuing to stir for 24 hours, move into hydrothermal In the reaction kettle, stand at 100° C. for crystallization for 24 hours, wash, filter and dry to obtain ordered ultramicroporous silicon dioxide precursor powder.

[0023] Carry out X-ray diffraction test to the product precursor of embodiment 1~4 respectively, the result is by figure 1 It can be seen that as the addition of HCl gradually decreases, the pH value of the system gradually increases, the sharpness and...

Embodiment 5~7

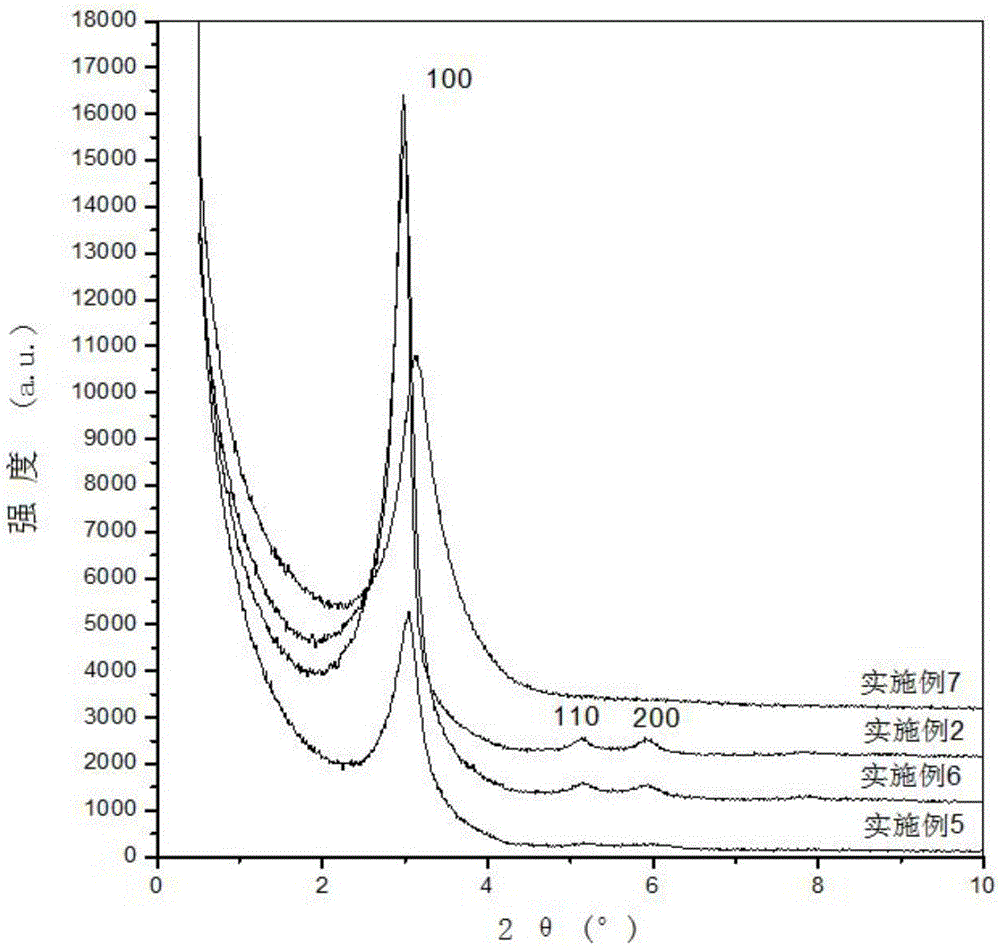

[0025] The preparation method is the same as in Example 2, except that the addition of DTAB is changed to prepare ultra-microporous silica, and the material ratio is SiO 2 :DTAB:HCl:H 2 O=1.0: (0.1~0.25): 1.9:808.0, wherein the addition amount of DTAB, embodiment 2 is 0.2, embodiment 5 is 0.1, embodiment 6 is 0.15, embodiment 7 is 0.25.

[0026] Carry out X-ray diffraction test to the product precursor of embodiment 5~7 respectively, and compare with embodiment 2, the result is by figure 2 It can be seen that with the gradual increase of the amount of DTAB added, the sharpness and peak intensity of the diffraction peaks of the samples show a trend of increasing first and then decreasing. When the material ratio is SiO 2 : DTAB = 1: 0.2, the sample at 2θ = 2.98°, 5.17° and 5.91° (d 100 =2.96nm,d 110 = 1.71nm, d 200 =1.49nm) the 100, 110 and 200 crystal plane diffraction peaks of the hexagonal phase appear respectively ( figure 2 -Example 2), illustrating that the sample...

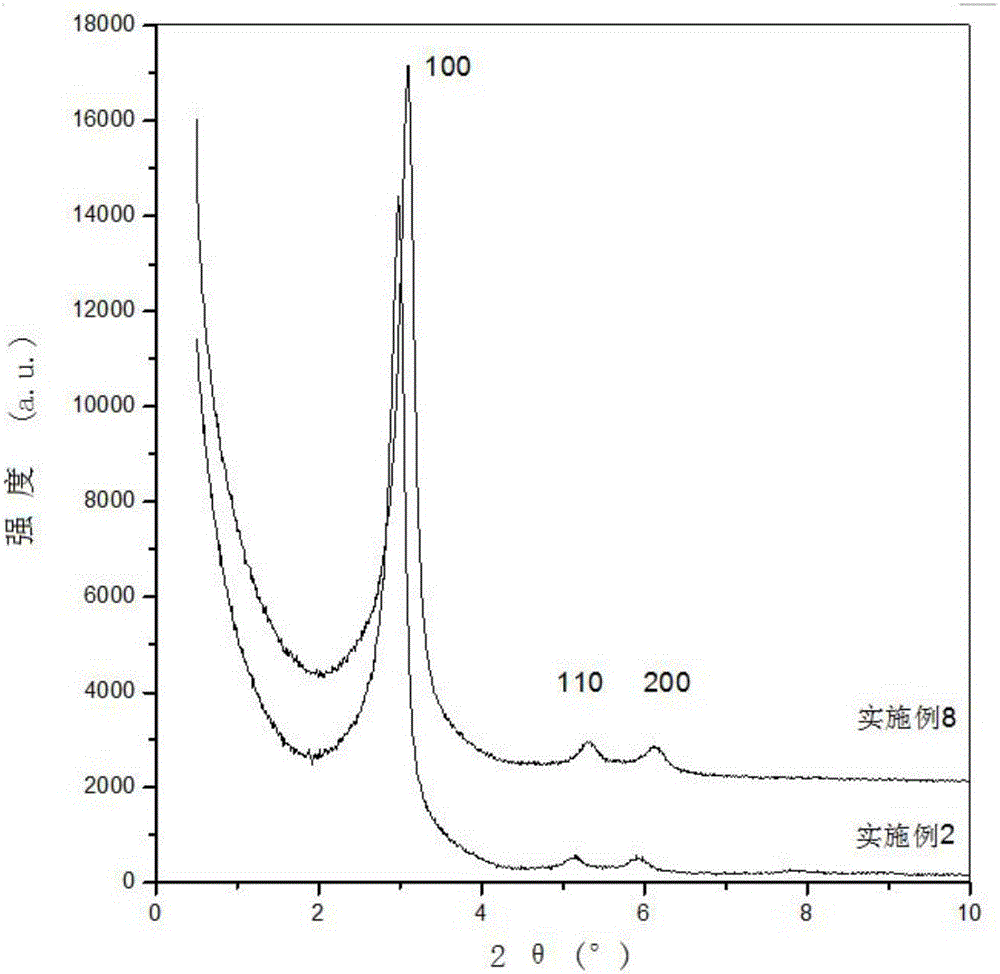

Embodiment 8

[0028] The preparation conditions of the ultramicroporous silica precursor are the same as in Example 2, and the precursor is heated to 823K for calcination at a rate of 1K / min for 4h, and the calcined sample is at 2θ=3.11°, 5.33° and 6.14° (d 100 =2.84nm,d 110 = 1.66nm, d 200 =1.44nm) the 100, 110 and 200 crystal plane diffraction peaks of the hexagonal phase appear respectively ( image 3 ), indicating that the sample still maintains a highly ordered hexagonal ultramicroporous structure after calcination.

[0029] The transmission electron microscope characterization of embodiment 8 sees Figure 4 , the sample shows a regular and orderly channel structure in the direction of parallel channels ( Figure 4 .a), in the direction perpendicular to the channel, the sample still shows unconventional long-range ordered hexagonal ultramicropore channels ( Figure 4.b), the pore size is about 1.8nm, and the hole wall is 1nm.

[0030] N of Example 8 2 Adsorption-desorption charac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com