Metal loaded vanadic oxide catalyst and preparation method and application thereof

A vanadium pentoxide catalyst and vanadium pentoxide technology are applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., which can solve the problem of difficult separation of catalysts and products, Poor activity and selectivity, long process route, etc., to achieve the effect of improving activity and product selectivity, optimizing catalytic performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

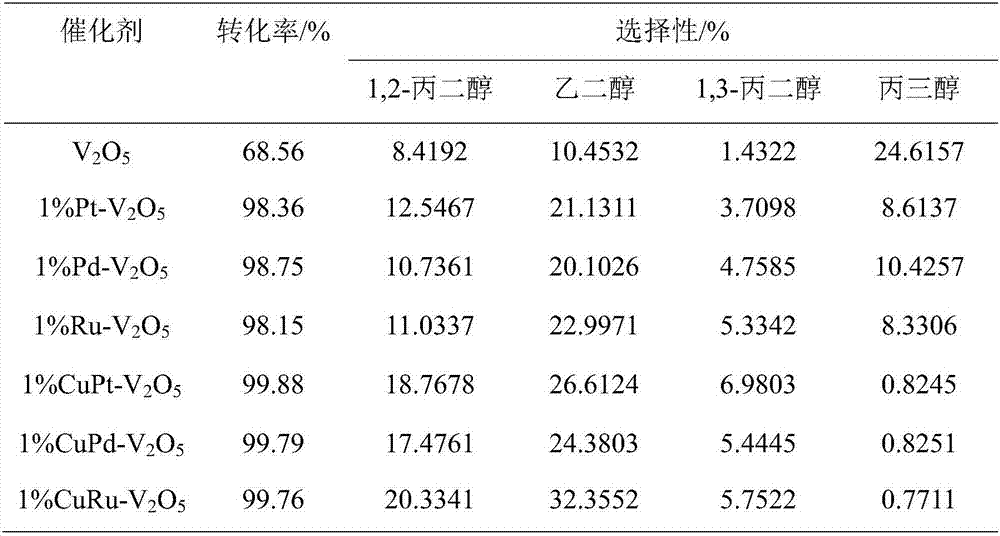

Embodiment 1

[0030] Preparation of vanadium pentoxide catalyst: Weigh 5.85g of ammonium metavanadate and dissolve it in 50ml of deionized water at 60°C, stir until completely dissolved, add 9.60g of citric acid, stir at constant temperature for 30min, and form a dark blue sol Shape; heat up to 90°C, stir at constant temperature to evaporate water until it forms a gel, and keep foaming at 120°C in an oven for 12 hours. After being ground into powder, set the temperature of the muffle furnace at 550°C, and bake in the air atmosphere for 3.5 hours to obtain yellow vanadium pentoxide powder.

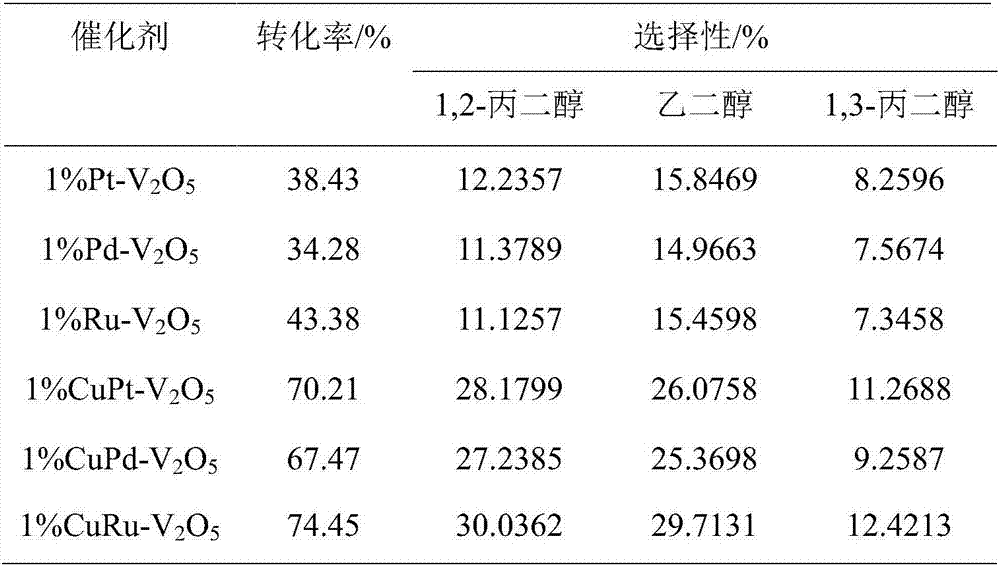

Embodiment 2

[0032] Preparation of single metal-supported catalyst: Weigh 5.85g of ammonium metavanadate and dissolve it in 50ml of deionized water at 60°C, stir until completely dissolved, add 9.60g of citric acid, stir at constant temperature for 30min, and form a dark blue sol Slowly add the chloroplatinic acid solution of 0.53g / 100ml in 22.8ml concentration, stir and disperse evenly, then under stirring at room temperature, utilize autosampler to inject the sodium borohydride that concentration is 0.34g / 100ml with the speed of 0.5ml / min Solution 40ml, reduce the loaded metal. Raise the temperature to 90°C, stir at a constant temperature to evaporate water until it forms a gel, and keep it in an oven for 12 hours at 120°C for foaming. After grinding into powder, set the muffle furnace temperature to 550°C, and bake in air atmosphere for 3.5h. The obtained catalyst contains 1wt% platinum, expressed as 1wt%Pt / V 2 o 5 .

[0033] Other conditions remain unchanged, the added chloroplatin...

Embodiment 3

[0035]Preparation of bimetallic supported catalyst: Weigh 5.85g of ammonium metavanadate and dissolve it in 50ml of deionized water at 60°C, stir until completely dissolved, add 9.60g of citric acid, stir at constant temperature for 30min, and form a dark blue sol Slowly add copper nitrate aqueous solution containing 0.05g copper ions and 22.8ml concentration of chloroplatinic acid solution of 0.53g / 100ml, stir and disperse evenly, then under stirring at room temperature, utilize an autosampler to inject at a speed of 0.5ml / min 80ml of sodium borohydride solution with a concentration of 0.34g / 100ml was used to reduce the loaded metal. Raise the temperature to 90°C, stir at a constant temperature to evaporate water until it forms a gel, and keep it in an oven for 12 hours at 120°C for foaming. After being ground into powder, set the temperature of the muffle furnace to 550°C, and bake in the air atmosphere for 3-3.5h. The resulting catalyst contains 1% platinum, expressed as 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com