Method for preparing oligomeric rosin by taking slash pine rosin as raw material

A technology of slash pine and rosin, applied in the field of new materials, can solve the problems of large solvent loss, large acid residue and acid-containing wastewater, uneven rubber surface, etc., and achieve long reaction time, high cost and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

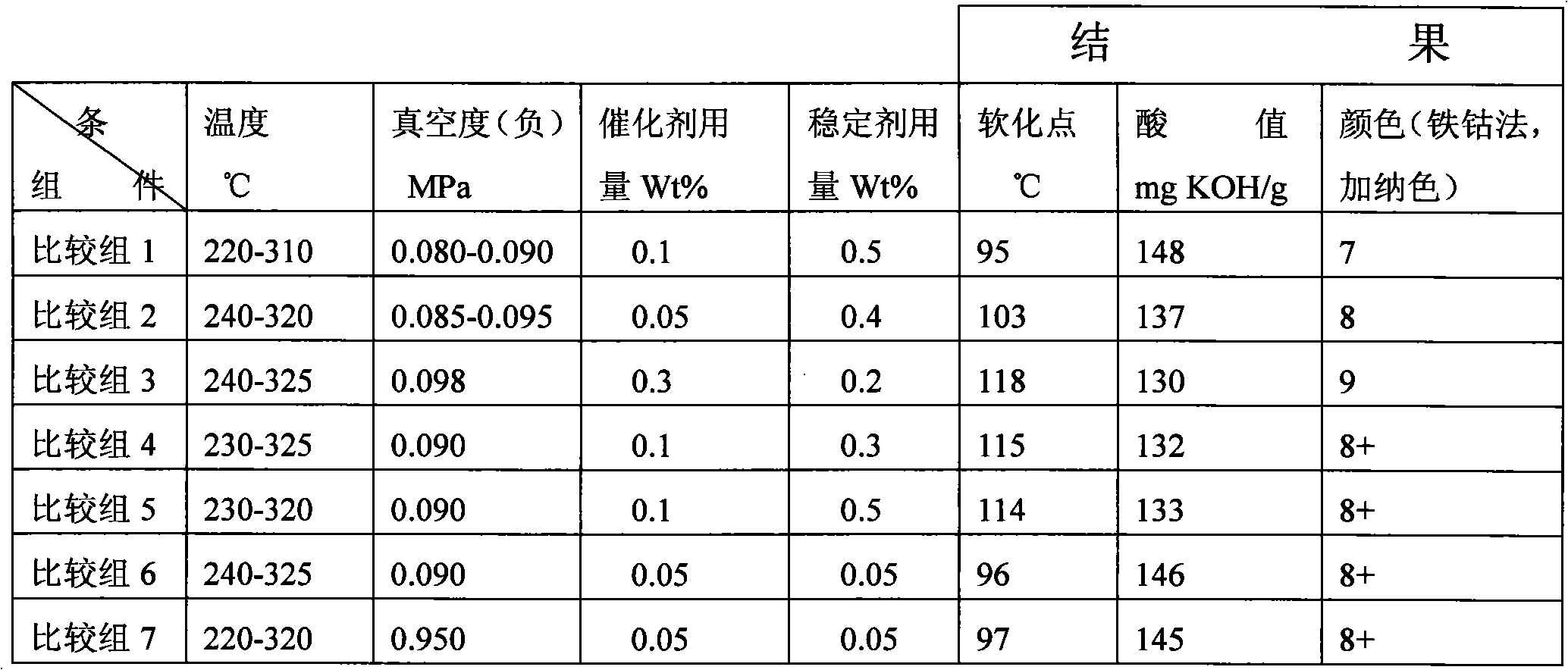

[0016] In the melting tank, the wetland pine rosin is heated and melted into a liquid state, and then sent to the reactor for heating, the temperature is 220-310 ° C, the vacuum degree is minus 0.080-0.090 MPa, the softening point of the obtained oligomeric rosin is 95 ° C, and the acid value is 148 (mgKOH / g), color 7 (iron cobalt method, Ghana color).

Embodiment 2

[0018] The preparation method is the same as implementation 1: the conditions are: temperature 230-320°C, vacuum degree negative 0.085-0.095MPa, the softening point of the obtained oligomeric rosin is 103°C, the acid value is 137 (mg KOH / g), and the color is 8 (iron-cobalt method , Ghana color).

Embodiment 3

[0020] The preparation method is the same as implementation 1: the conditions are: temperature 240-325°C, vacuum degree negative 0.098MPa, the softening point of the obtained oligomeric rosin is 118°C, acid value 130 (mg KOH / g), color 9 (iron-cobalt method, Ghana color)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com