Square steel tubular column with internally tangent ring-shaped stirrup restraint and high-strength concrete

A technology of high-strength concrete and square steel pipe, applied in the directions of columns, piers, pillars, etc., can solve the problems of complicated construction of high-strength concrete joints of round steel pipes, many construction procedures, low flexural rigidity and flexural bearing capacity, etc., so as to shorten the construction time. The effect of period, convenient construction, high flexural bearing capacity and flexural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

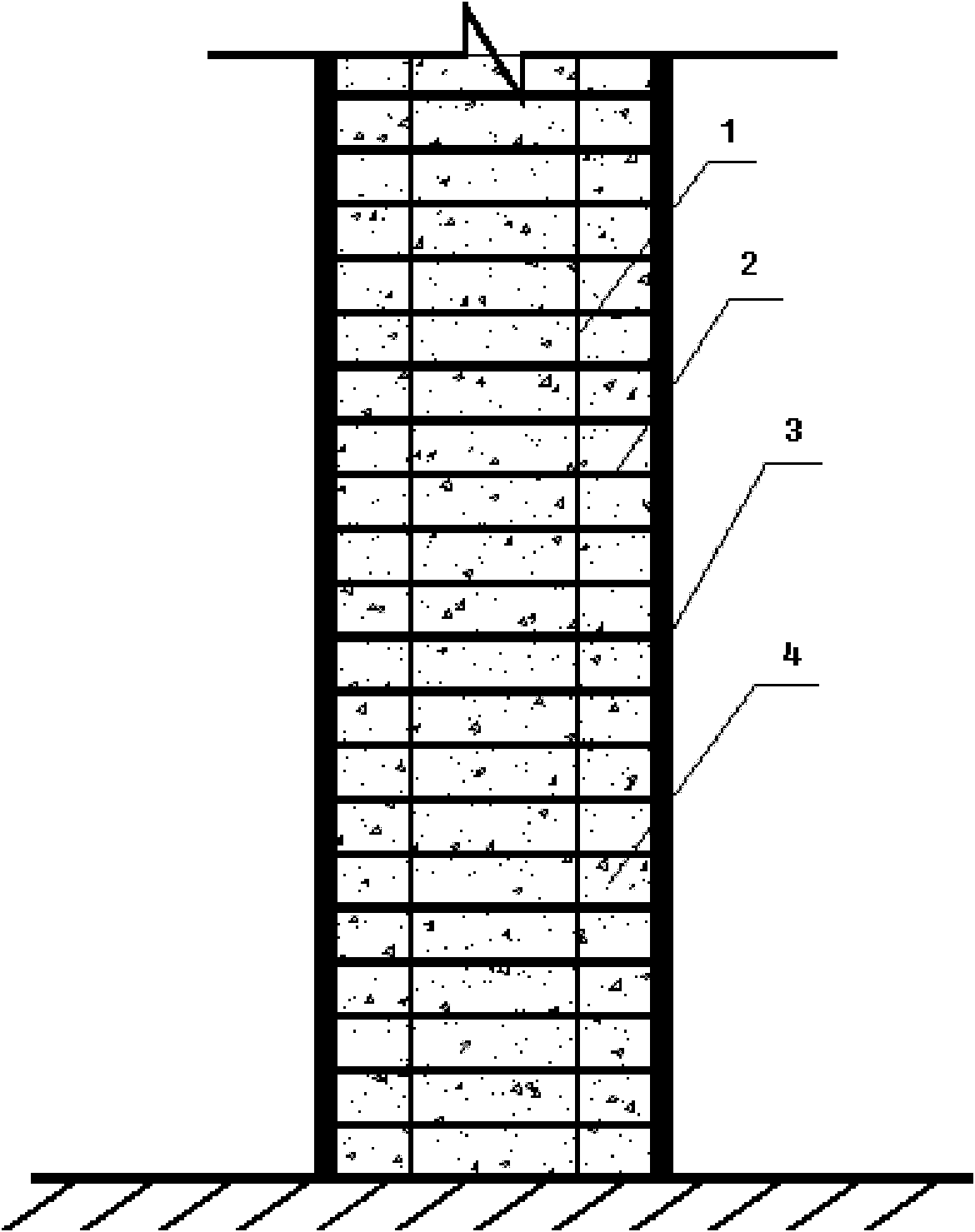

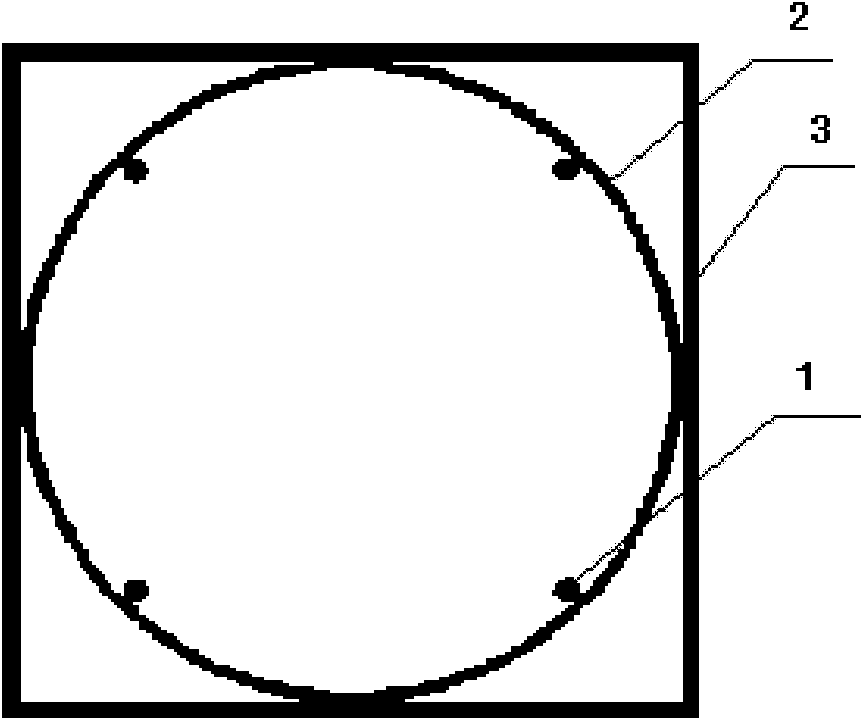

[0033] See attached figure 1 , 2 3. The high-strength concrete column constrained by the inscribed annular stirrup of the square steel pipe of the present invention comprises a square steel pipe 4, a stirrup 2, a longitudinal reinforcement 1, and a high-strength concrete 3, and the longitudinal reinforcement 1 is at least three along the 4 axes of the square steel pipe. set in the square steel pipe 4; the stirrup 2 is a single ring, the stirrup 2 is arranged along the axial direction of the longitudinal bar 1, and the distance between two adjacent ring stirrups is 30~ 80mm, the stirrup 2 is tangent to the inner surface of the square steel pipe 4 and fixed with the longitudinal bar 1 by spot welding or binding; the square steel pipe is poured with high-strength concrete 3, and the volume steel content of the square steel pipe The ratio of steel content to the volume of the stirrup is between (1:3) and (3:1).

Embodiment 2

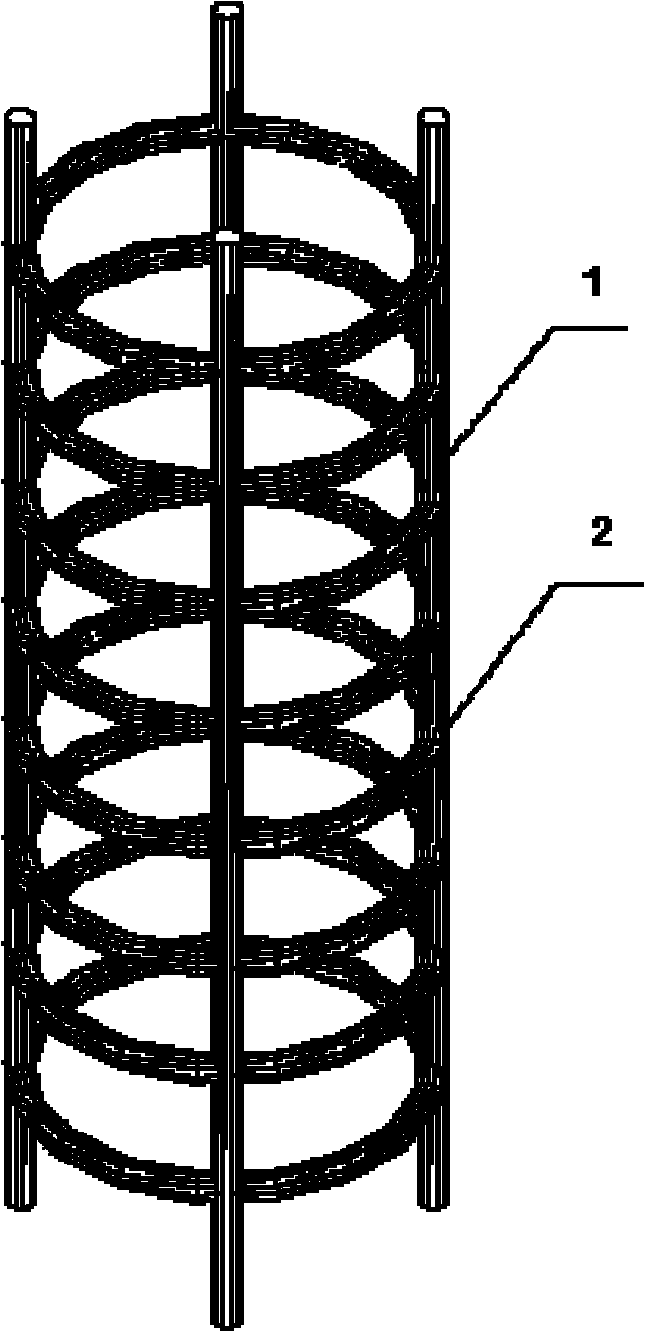

[0035] See attached figure 1 , 2 , 4, the high-strength concrete column constrained by the inscribed annular stirrup of the square steel pipe of the present invention comprises a square steel pipe 4, a stirrup 2, a longitudinal reinforcement 1, and a high-strength concrete 3, and the longitudinal reinforcement 1 is at least three and along the 4 axes of the square steel pipe set in the square steel pipe 4; the stirrup 2 is a helix, and the stirrup 2 is arranged along the axial direction of the longitudinal bar 1, and the pitch of the helix is 30-80mm, and the stirrup 2 and the The inner surface of the square steel pipe 4 is tangent to the longitudinal reinforcement 1 and fixed by spot welding or binding; the square steel pipe is poured with high-strength concrete 3, and the ratio of the volume steel content of the square steel pipe to the volume steel content of the stirrup is The ratio is between (1:3)~(3:1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com