Self-adaptive damping variable ultra-precise vibration absorber

An ultra-precision, shock absorber technology, applied in the direction of gas shock absorbers, etc., can solve the problems of inability to fully realize ceiling damping, high-frequency attenuation rate effects, etc., and achieve good attenuation, active adjustable damping, and low stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

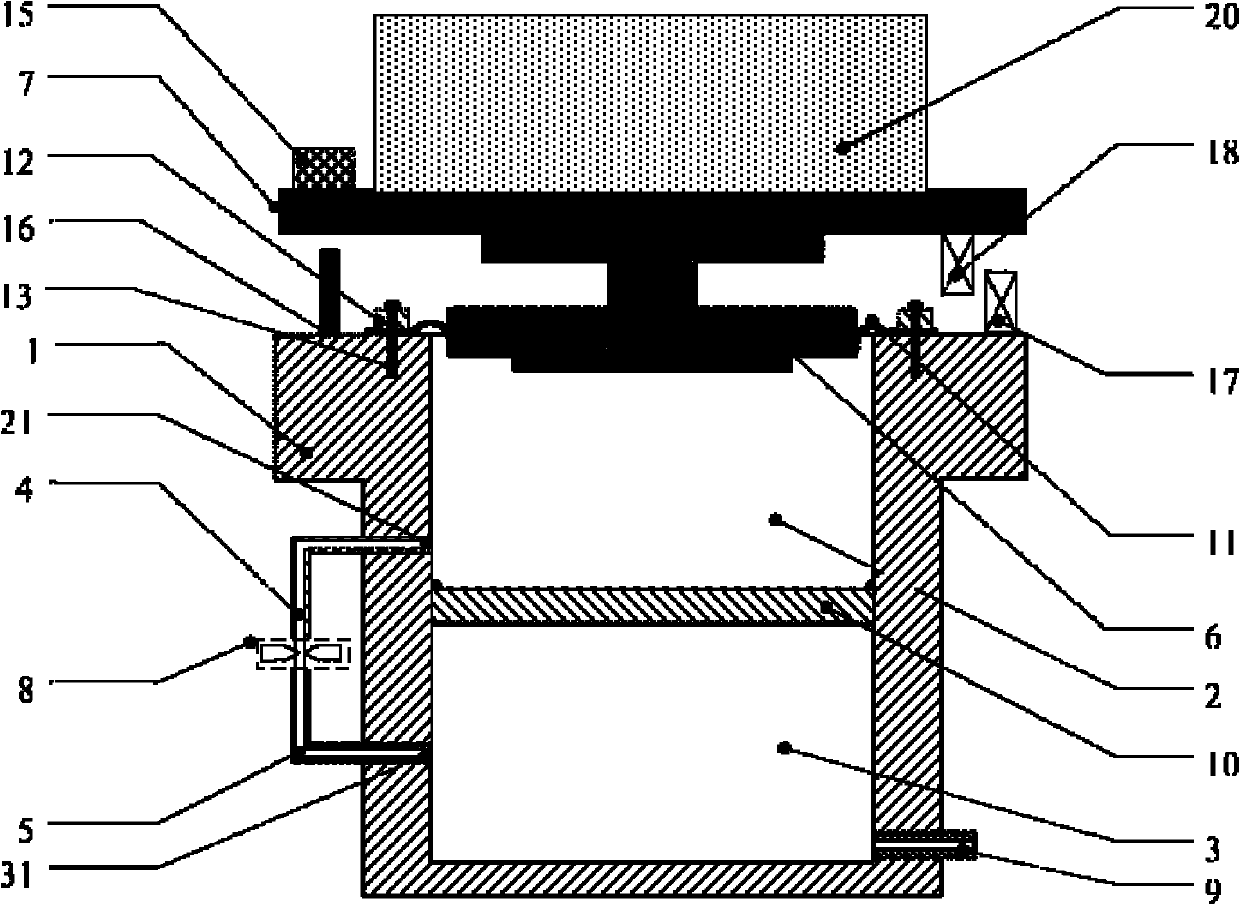

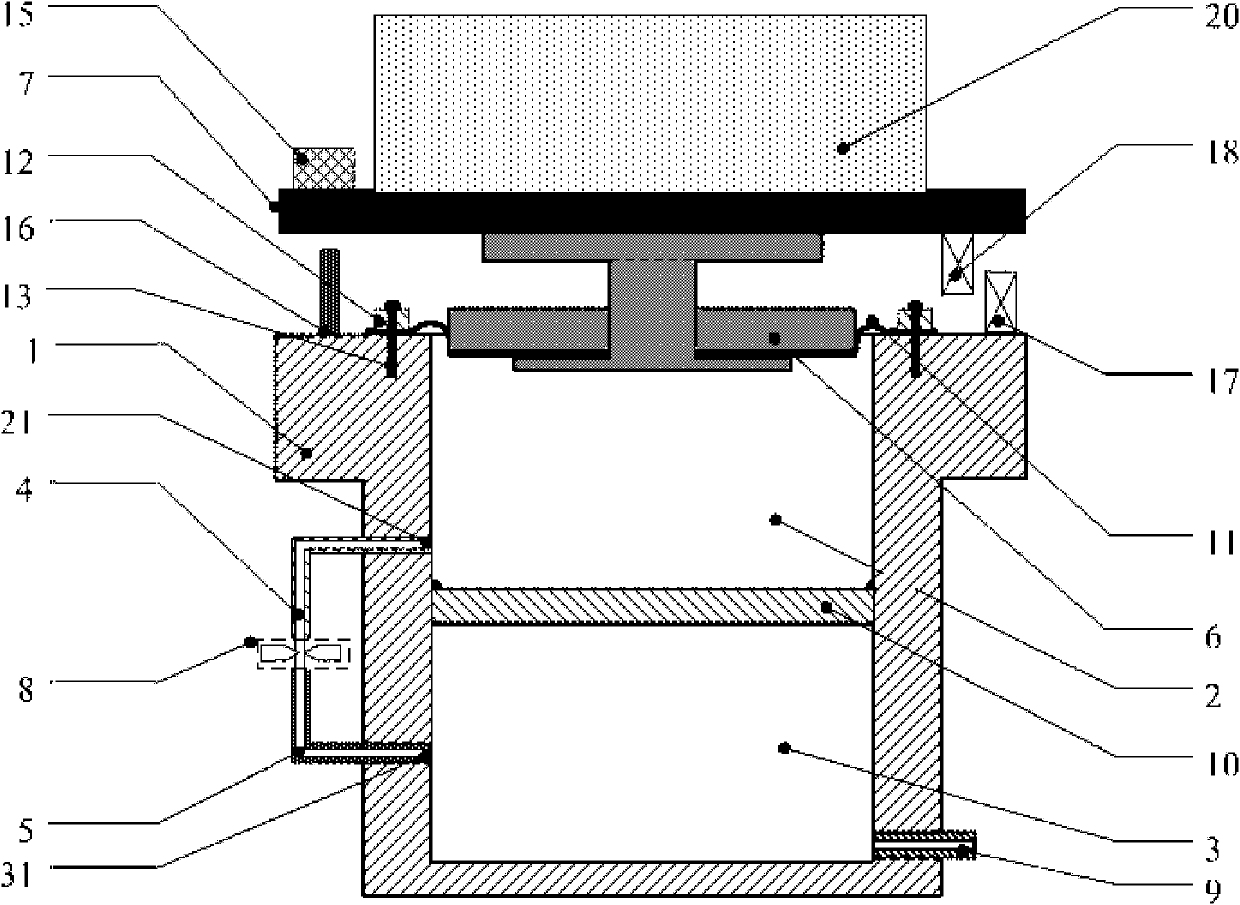

[0018] The structure and working principle of the present invention are further described below in conjunction with design examples and accompanying drawings.

[0019] Such as figure 1 As shown, the precision shock absorber provided by the present invention structurally includes two parts, a passive damping component and an active actuator.

[0020] The passive damping part in the present invention is a double-chamber air spring, which includes a metal shell 1, an upper chamber 2, a lower chamber 3, a piston mechanism 6, a load connecting plate 7, a membrane structure, a throttle valve 8 and an inlet Air port 9. The metal shell 1 has an open cylindrical shape on the outside and a hollow inside, separated by a partition 10 into upper and lower hollow parts, and its section is H-shaped. The lower hollow space forms the lower chamber 3 , and the upper hollow space and the piston mechanism 6 are sealed and connected through a membrane structure to form the upper chamber 2 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com