Vertical anti-coking pulverized coal hot air furnace

An anti-coking and hot blast stove technology, which is applied to air heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as uneven air mixing, unstable high temperature hot blast temperature, and affecting the normal operation of hot blast stoves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

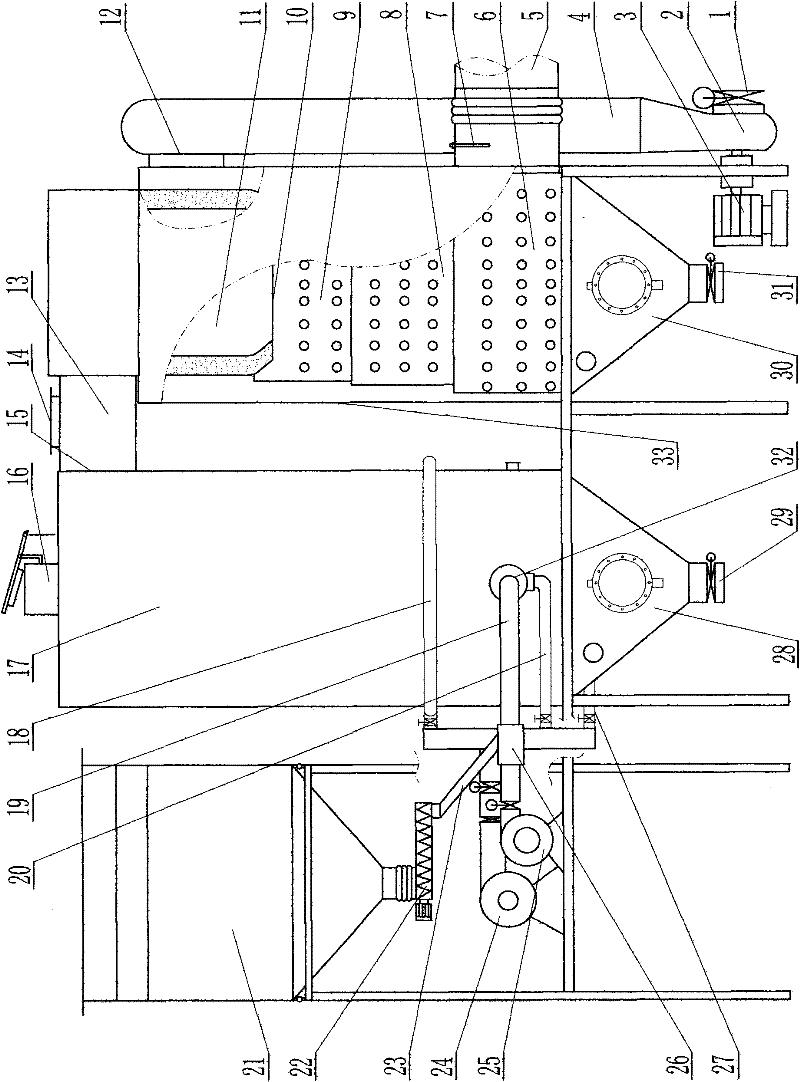

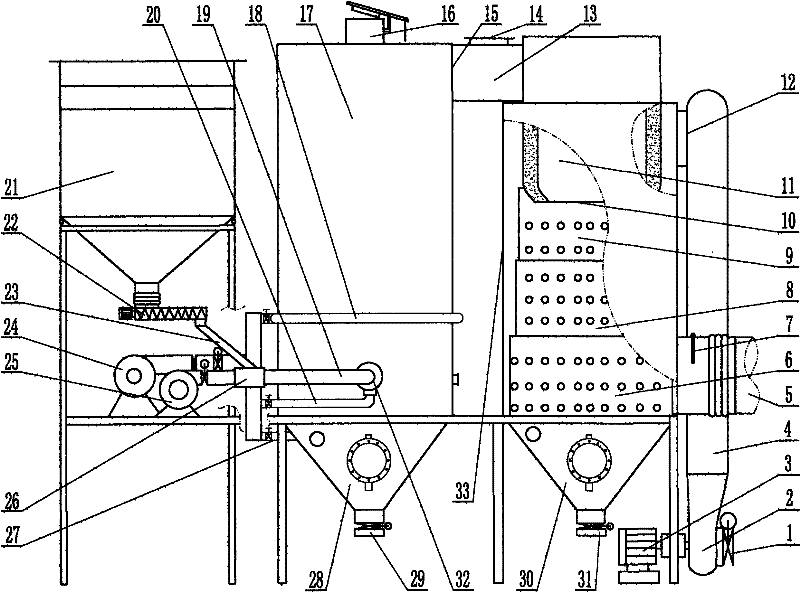

[0010] figure 1 Among them, the vertical anti-coking pulverized coal hot air stove, which contains a feeding system, a high-temperature combustion chamber 17, a combustion-supporting system, an auxiliary combustion and mixing system, and a detection and control device. The high-temperature combustion chamber 17 is a vertical structure shape, the chamber contains a cylindrical shell, the bottom of the shell is provided with an ash hopper 28, its top is provided with a release valve 16, the top of its surface is provided with an air outlet 15, its surface The lower part of the feed port 32 is provided. The bottom of the ash hopper 28 is provided with a first ash discharge valve 29 . The feeding system includes a pulverized coal bin 21, a conveying device 22, a conveying pipe 23, a pulverized coal fan 25, a pulverized air mixer 26, and a coal feeding pipe 19. The conveying device 22 is arranged at the bottom of the pulverized coal bin 21, and one end of the conveying pipe 23 It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com