Bushing-type high temperature heat storage device applied to solar heat utilization

A technology for solar thermal and thermal storage devices, applied in solar thermal devices, solar thermal power generation, heating devices, etc., to achieve the effects of small phase segregation, high latent heat of phase transition, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

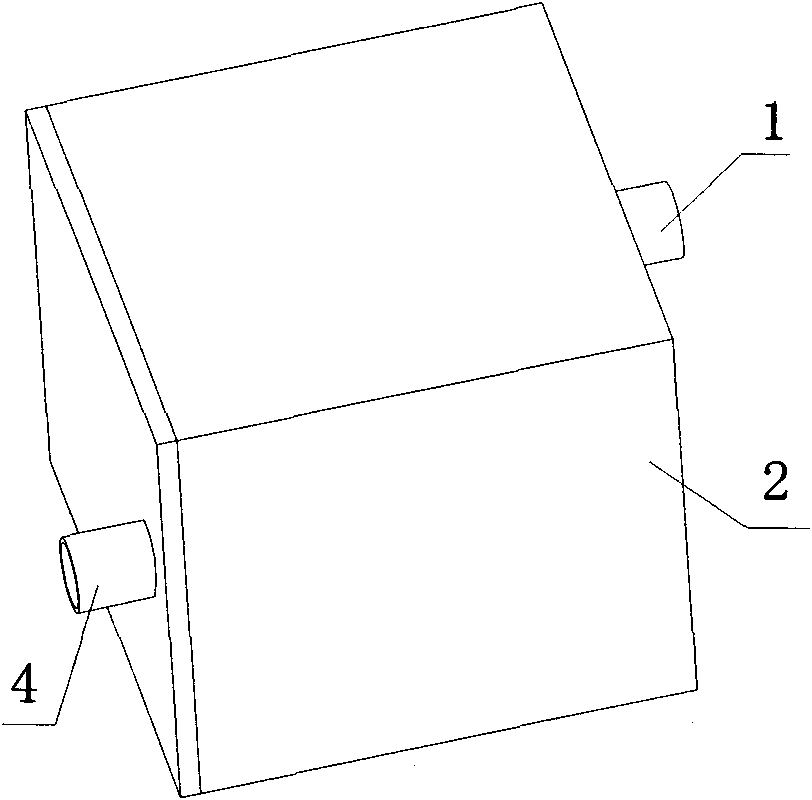

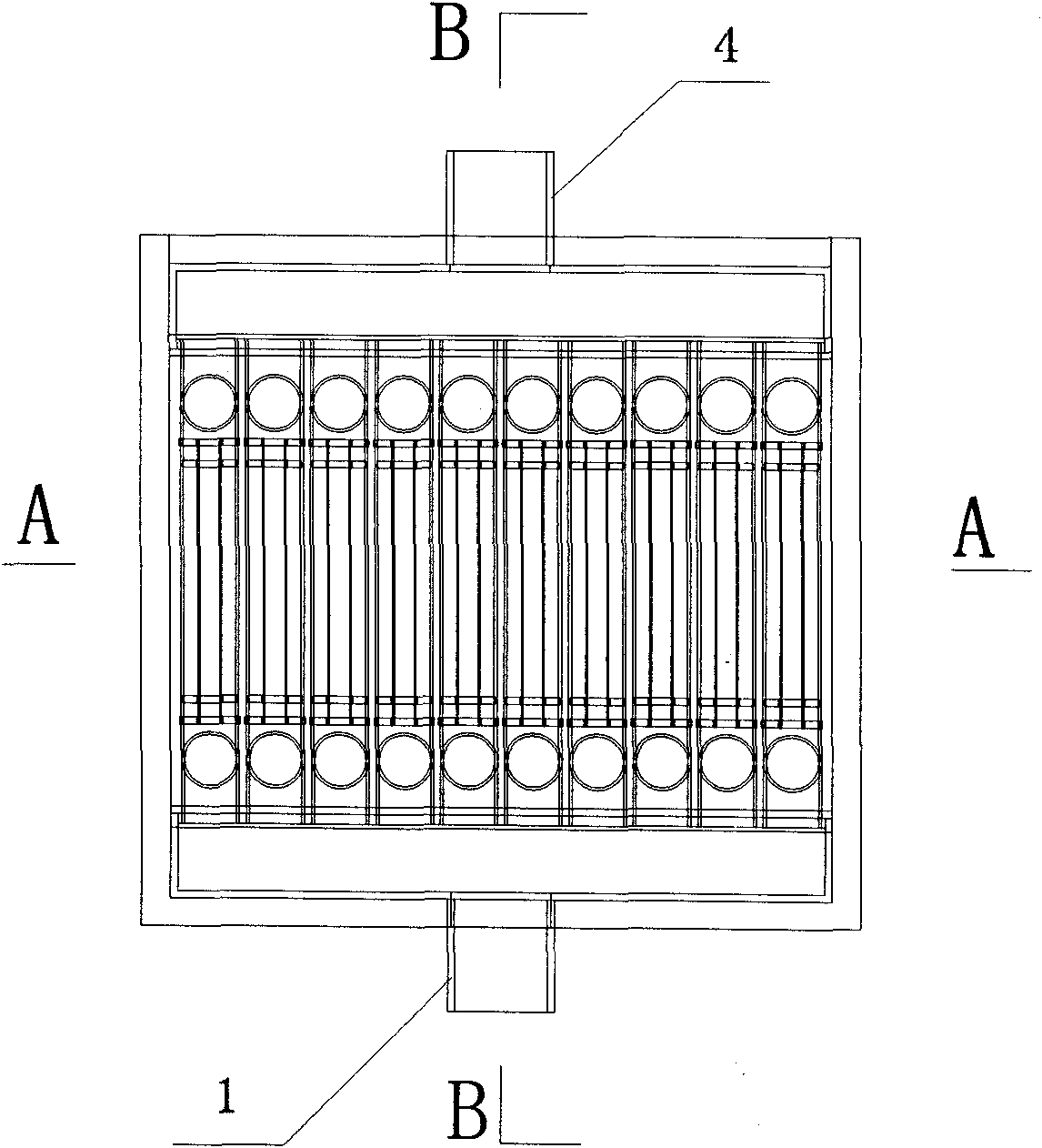

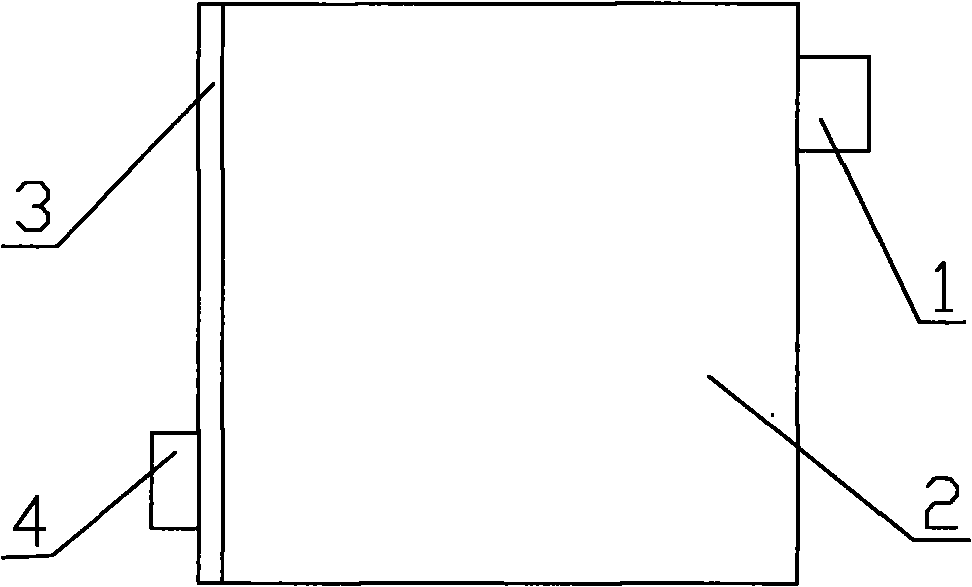

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, a sleeve-type high-temperature heat storage device used in solar heat utilization includes an air inlet pipe 1, a heat storage chamber body 2, a heat storage chamber door 3, an air outlet pipe 4, a first ventilation cavity 5, The second ventilation cavity, heat storage material containing pipe 6, serpentine pipe, air circulation pipe connection plate 9, heat storage material containing pipe support 10, thermal insulation material, heat storage material;

[0025] The thermal storage chamber body 2 is composed of the outer wall of the thermal storage room and the inner wall of the thermal storage room. A sealed insulation cavity is formed between the outer wall of the thermal storage room and the inner wall of the thermal storage room. The thermal insulation cavity is filled with thermal insulation materials. It is a cube, and the outer wall of the heat storage room and the inner wall ...

Embodiment 2

[0041] Basically the same as Example 1, the difference is:

[0042] Al-Cu-Mg-Zn high-temperature phase change heat storage material, which is prepared from high-purity Al, Al-Cu master alloy, high-purity Mg and high-purity Zn raw materials, the mass percentage of each raw material is: high-purity Al 13 %, Al-Cu master alloy 52%, high-purity Mg 15%, high-purity Zn 20%;

[0043] The mass purity of the high-purity Al is ≥99.70%, the mass purity of the Al-Cu master alloy is ≥99.00%, the mass purity of the high-purity Mg is ≥99.50%, and the mass purity of the high-purity Zn is ≥99.50%.

[0044] The preparation method of the above-mentioned Al-Cu-Mg-Zn high-temperature phase change heat storage material (its preparation process is simple, only need to use the conventional aluminum-magnesium alloy smelting method), it includes the following steps:

[0045] 1) Ingredients: the mass percentage of each raw material is: high-purity Al 13%, Al-Cu master alloy 52%, high-purity Mg 15%, hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com