Optical element and method for making the same, master and method for making the same, and display apparatus

A technology of optical elements and structures, applied in the directions of optical elements, optics, diffusing elements, etc., can solve the problem of easy generation of stripes, and achieve the effect of high contrast, high anti-glare, and suppression of stripes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0082] (1) First embodiment (example of utilizing laser processing to make embossing roller):

[0083] (1.1) Structure of liquid crystal display device

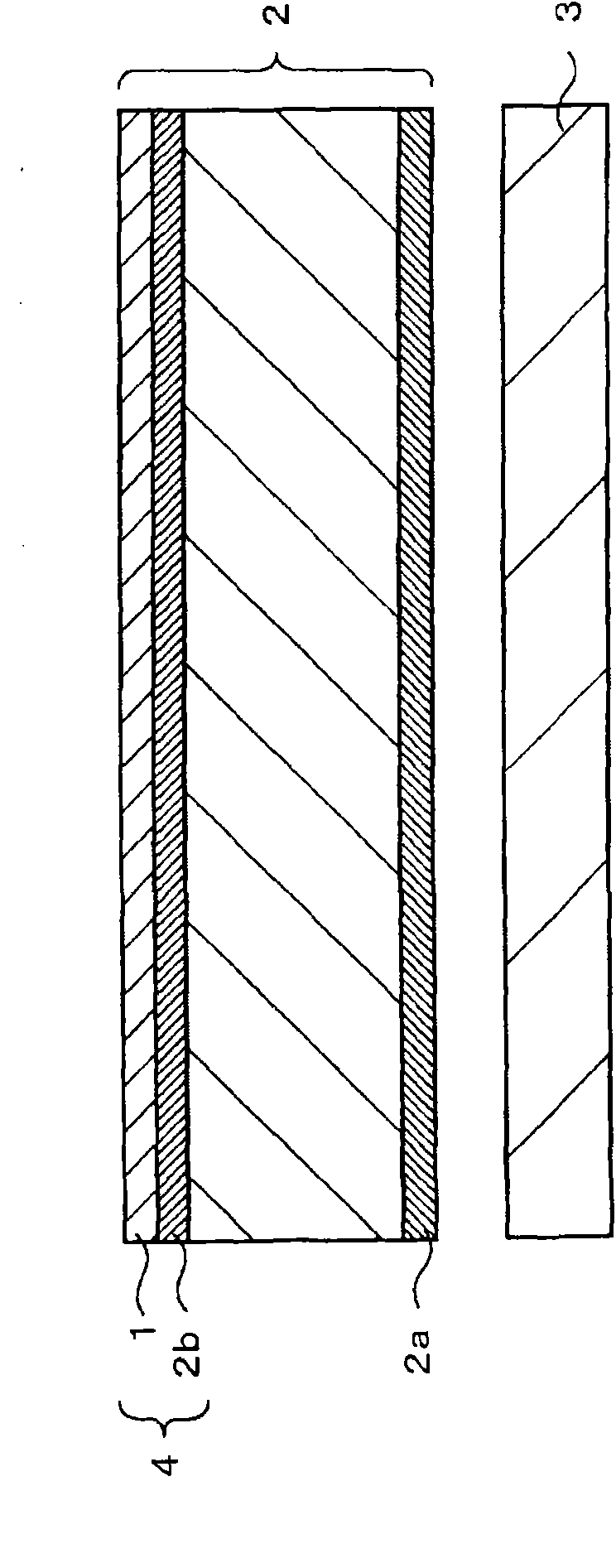

[0084] (1.2) Structure of optical film

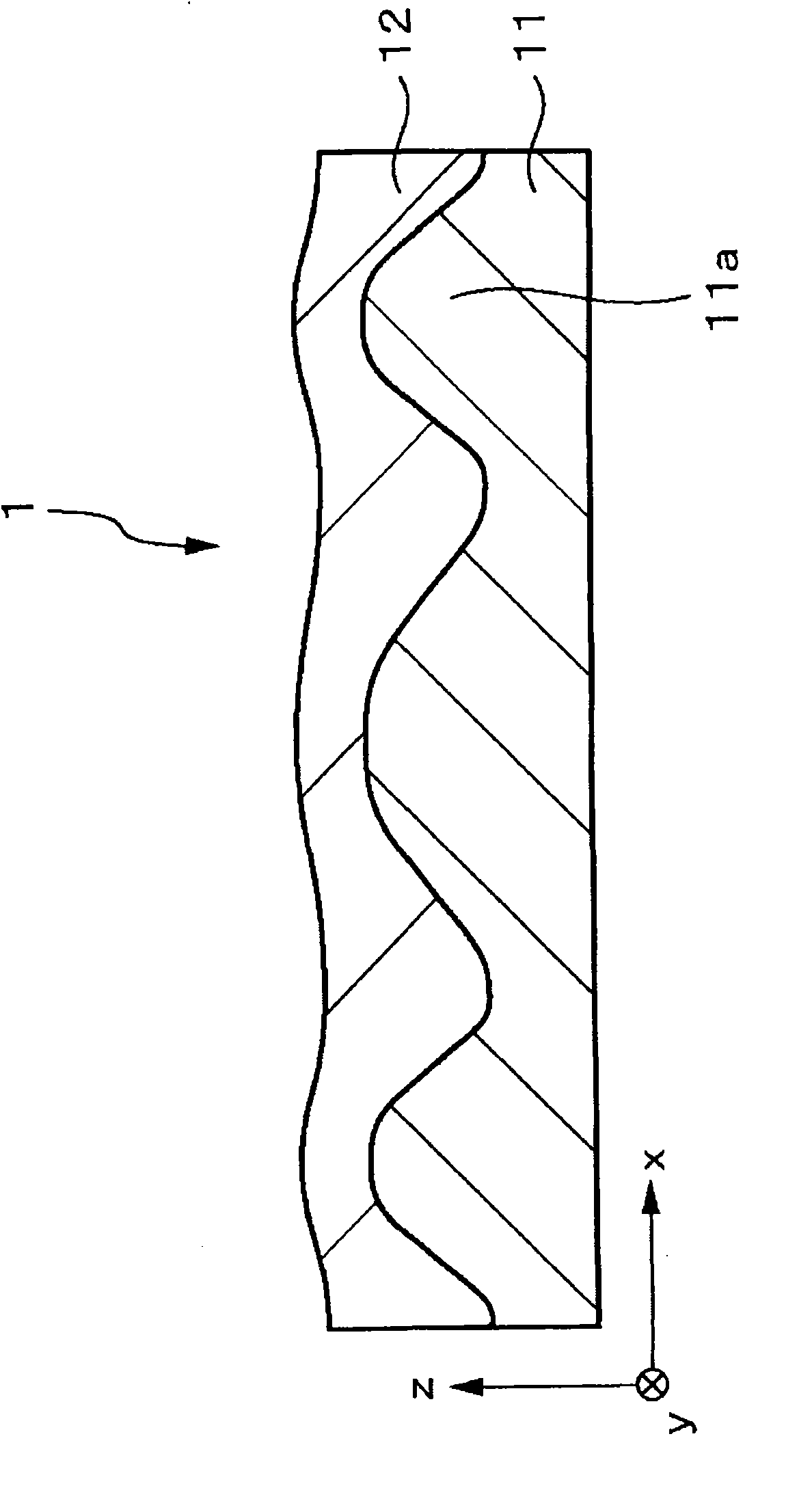

[0085] (1.3) Embossing replication device

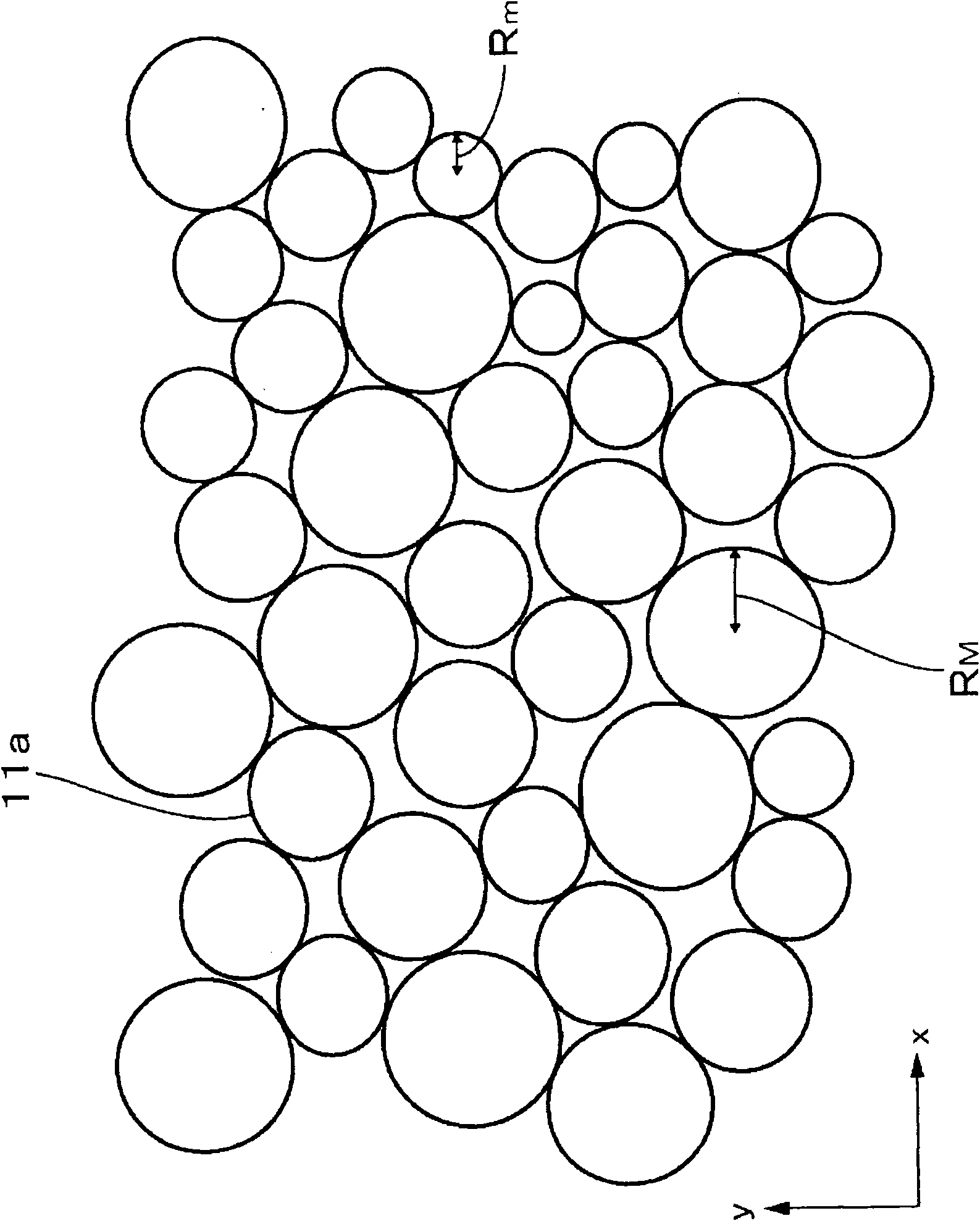

[0086] (1.4) Method of arranging circles on transfer rollers

[0087] (1.5) About random point generation algorithm

[0088] (1.5.1) Generation method of data on the X axis 1

[0089] (1.5.2) Generation method of data on the X-axis 2

[0090] (1.5.3) Circle filling method 1

[0091] (1.5.4) Circle filling method 2

[0092] (1.5.5) Tiling method

[0093] (1.6) Graphics generation device

[0094] (1.7) Manufacturing method of optical film

[0095] (2) Second Example (Example of Fabricating an Embossing Roll by Etching)

[0096] (3) Third embodiment (an example of further forming an antistatic layer)

[0097] (4) Fourth embodiment (an example in which an anti-reflection layer is further formed on the surface)

no. 5 example

[0098] (5) Fifth Embodiment (First Example of ANR Film)

no. 6 example

[0099] (6) Sixth Embodiment (Second Example of ANR Film)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ten point average roughness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com