Granulation technology of onion powder

A granulation technology, a technology of onion powder, applied in the field of food processing, can solve the problems of easy adhesion of onion powder, easy paste at high temperature, low temperature resistance, etc. bubble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

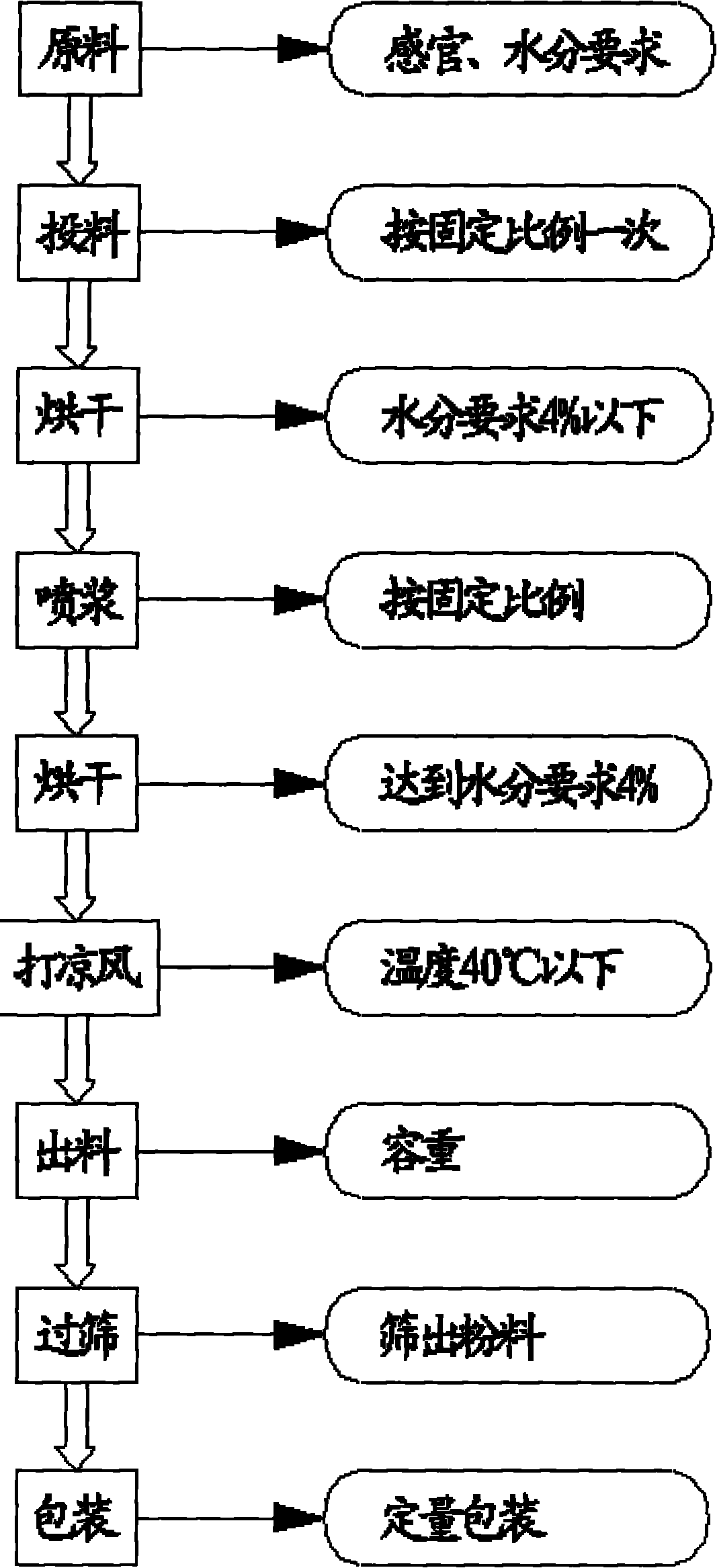

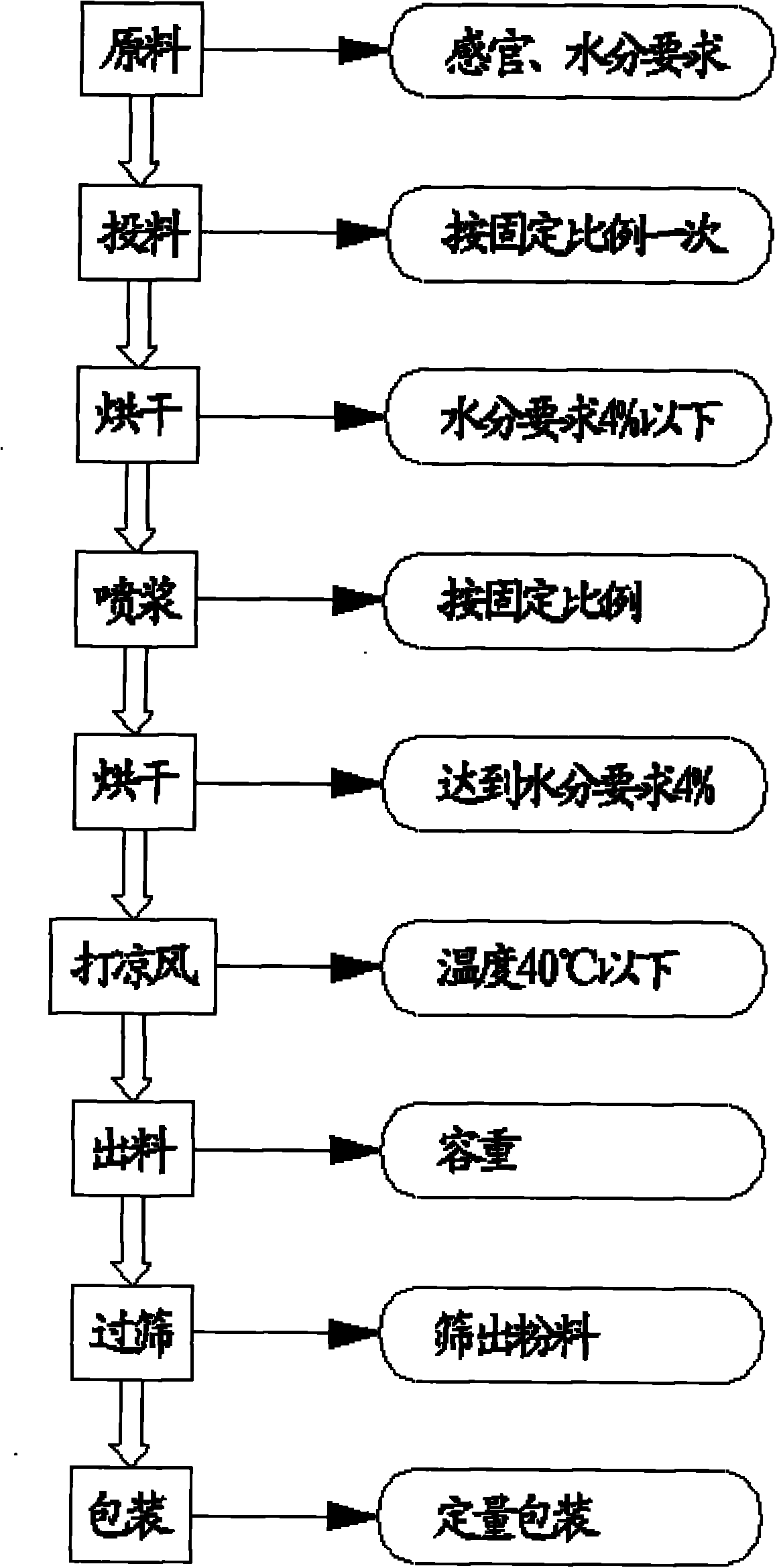

Method used

Image

Examples

Embodiment 1

[0024] at 1m 3 Put 240kg of onion powder into the granulation pot at one time, pass hot air at 130°C for 15 minutes, the average speed of spraying is 0.5 liters / minute, the amount of spraying is 25kg, the volume of finished product is 250ml / 100g, and the finished product is 180kg.

Embodiment 2

[0026] at 2m 3 Put 480kg of onion powder into the granulation pot at one time, pass hot air at 120°C for 20 minutes, the spraying speed is 0.5 liters / minute, the spraying amount is 50kg, the finished product has a density of 230ml / 100g, and the finished product is 350kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com