Method for separating alpha s-casein

A separation method and casein technology, which can be applied to the preparation methods of peptides, chemical instruments and methods, animal/human peptides, etc., can solve the problems of cumbersome steps, long time consumption, etc., and achieve good application prospects, simple and easy operation, and effective The effect that is beneficial to development and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

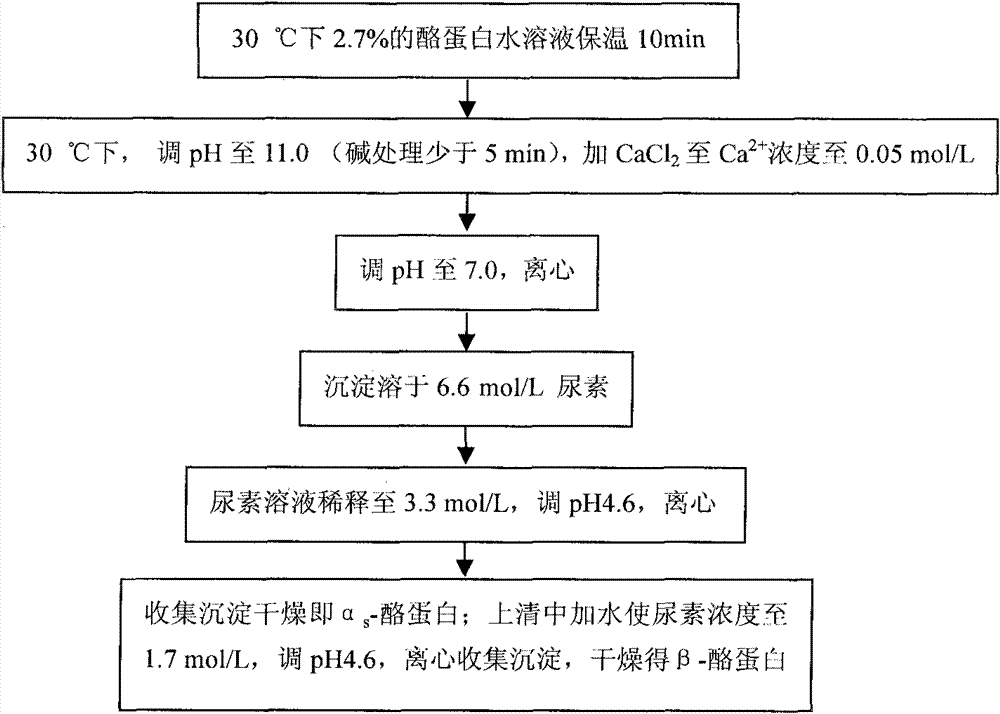

Method used

Image

Examples

Embodiment 1

[0021] (1) Weigh 6.75g of casein and dissolve it in water at 30°C, keep it at 30°C for 10 minutes to obtain an aqueous solution of casein with a mass-volume percentage concentration of 2.7%, adjust the pH value to 11.0, and let the solution stand for 3 minutes;

[0022] (2) Add CaCl to casein aqueous solution 2 solution to Ca 2+ When the concentration reaches 0.05mol / L, adjust the pH value to 7.0, centrifuge at 3000rmp for 10min, and collect the precipitate;

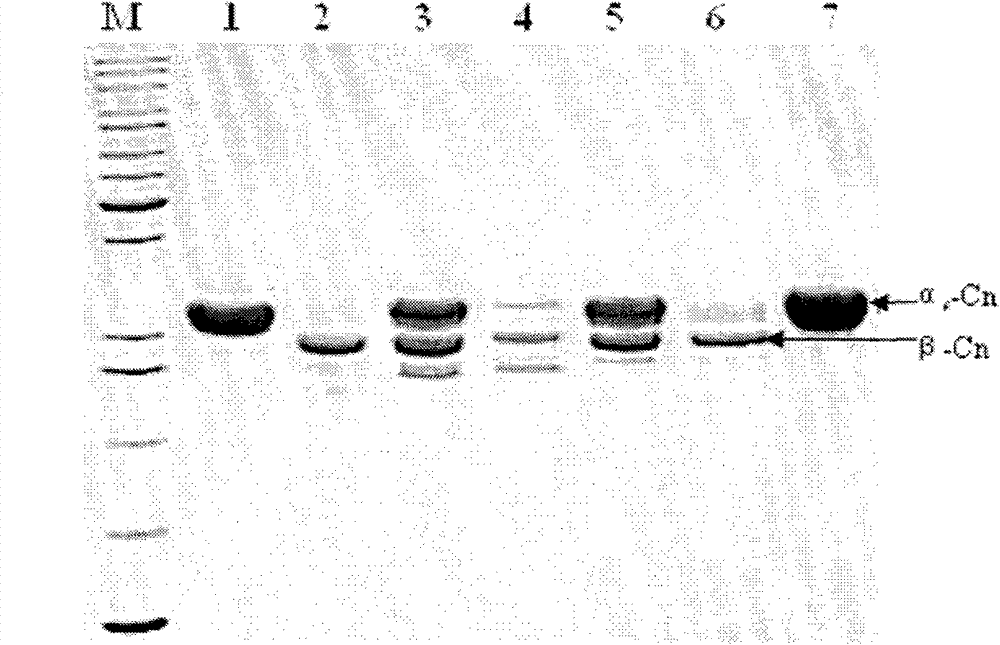

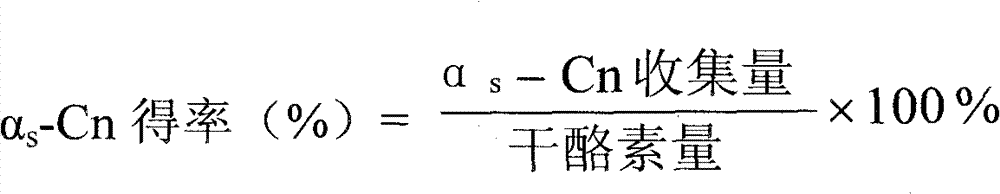

[0023] (3) Dissolve the precipitate in 6.6mol / L urea aqueous solution, and the solution contains 1.8mol / L NaCl, then add distilled water to dilute the urea concentration to 3.3mol / L, adjust the pH value to 4.6, centrifuge at 3000rmp for 10min, respectively The supernatant and the precipitate were collected, and the precipitate was washed twice with water, then freeze-dried to obtain α s - casein;

[0024] (4) Add distilled water to the supernatant in step (3), so that the urea concentration in the solution reaches 1.7...

Embodiment 2

[0032] (1) Weigh 6.75g of casein and dissolve it in water at 30°C, keep it at 30°C for 10 minutes to obtain a casein aqueous solution with a mass-volume percentage concentration of 2.7%, then adjust the pH value to 11.0, and let the solution stand for 1 minute;

[0033] (2) Add CaCl to casein aqueous solution 2 solution to Ca 2+ When the concentration reaches 0.04mol / L, adjust the pH value to 7.0, centrifuge at 3000rmp for 10min, and collect the precipitate;

[0034] (3) Dissolve the precipitate in 6.6mol / L urea aqueous solution, and the solution contains 1.8mol / L NaCl, then add distilled water to dilute the urea concentration to 3.3mol / L, adjust the pH value to 4.6, centrifuge at 3000rmp for 10min, respectively The supernatant and the precipitate were collected, and the precipitate was washed 3 times with water, then freeze-dried to obtain α s - casein;

[0035] (4) Add distilled water to the supernatant in step (3), so that the urea concentration in the solution reaches 1...

Embodiment 3

[0038] (1) Weigh 6.75g of casein and dissolve it in water at 30°C, keep it at 30°C for 10 minutes to obtain an aqueous solution of casein with a mass-volume percentage concentration of 2.7%, then adjust the pH value to 11.0, and let the solution stand for 4 minutes;

[0039] (2) Add CaCl to casein aqueous solution 2 solution to Ca 2+ When the concentration reaches 0.06mol / L, adjust the pH value to 7.0, centrifuge at 3000rmp for 10min, and collect the precipitate;

[0040] (3) Dissolve the precipitate in 6.6mol / L urea aqueous solution, and the solution contains 1.8mol / L NaCl, then add distilled water to dilute the urea concentration to 3.3mol / L, adjust the pH value to 4.6, centrifuge at 3000rmp for 10min, respectively The supernatant and the precipitate were collected, and the precipitate was washed twice with water, then freeze-dried to obtain α s - casein;

[0041] (4) Add distilled water to the supernatant in step (3), so that the urea concentration in the solution reache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com