Sulfur solvent for cleaning sulphur deposition in wellhole

A technology for cleaning well bores and sulfur solvents, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., and can solve problems such as low solubility, limited sulfur load capacity, and long on-site operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

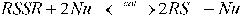

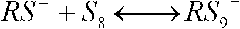

Method used

Image

Examples

Embodiment 1

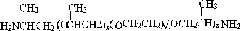

[0035] The main agent is 90% by weight of dimethyl disulfide DMDS, 3.0% by weight of the catalyst (the catalyst is composed of 80% by weight of diethanolamine and 20% by weight of sodium methylate), and the corrosion inhibitor is 7.0% by weight of β-diethyl Aminophenyl ketones.

[0036] When used at 90°C, the solubility of sulfur reaches 421g, the time t1 / 2 needed to dissolve 50% by weight of sulfur is 0.96 minutes, and the average dynamic corrosion rate of N80 coupons is 0.081g / h.m2. Visible pitting and pitting.

[0037] After 30 days of aging and maintenance at room temperature, at 90°C, the solubility of sulfur reaches 420g, the time t1 / 2 required to dissolve 50% of sulfur by weight is 0.99 minutes, and the average dynamic corrosion rate of N80 coupons is 0.080g / h.m2, The surface of the steel sheet is smooth and clean, without pitting and pitting corrosion visible to the naked eye.

Embodiment 2

[0039] The main agent is 90% by weight of dimethyl disulfide DMDS, 3.0% by weight of the catalyst (the catalyst is composed of 80% by weight of triethanolamine and 20% by weight of sodium methylate), and the corrosion inhibitor is 7.0% by weight of β-rosinamine phenyl ketones.

[0040] When used at 90°C, the solubility of sulfur reaches 431g, and the time t1 / 2 required to dissolve 50% by weight of sulfur is 0.72 minutes. The average dynamic corrosion rate of N80 coupons is 0.064g / h.m2. Visible pitting and pitting.

[0041] After 120 days of aging and maintenance at room temperature, at 90°C, the solubility of sulfur reaches 433g, the time t1 / 2 required to dissolve 50% of sulfur by weight is 0.74 minutes, and the average dynamic corrosion rate of N80 coupons is 0.066g / h.m2, The surface of the steel sheet is smooth and clean, without pitting and pitting corrosion visible to the naked eye.

Embodiment 3

[0043] The main agent is 90% by weight of dimethyl disulfide DMDS, 3.5% by weight of the catalyst (the catalyst is composed of 80% by weight of polyalkylene hydroxylamine and 20% by weight of sodium ethylate), and the corrosion inhibitor is 6.0% by weight of β-rosinaminophenyl ketone.

[0044] When used at 90°C, the solubility of sulfur reaches 465g, the time t1 / 2 required to dissolve 50% by weight of sulfur is 0.45 minutes, and the average dynamic corrosion rate of N80 coupons is 0.056g / h.m2. Visible pitting and pitting.

[0045]After 120 days of aging and maintenance at room temperature, at 90°C, the solubility of sulfur reaches 462g, the time t1 / 2 required to dissolve 50% of sulfur by weight is 0.47 minutes, and the average dynamic corrosion rate of N80 coupons is 0.058g / h.m2, The surface of the steel sheet is smooth and clean, without pitting and pitting corrosion visible to the naked eye.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com