Refrigeration Energy Saving Composition

A composition, mineral oil technology, used in lubricating compositions, sustainable manufacturing/processing, chemical industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

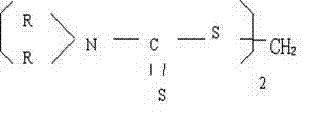

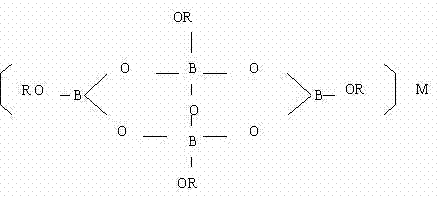

Method used

Image

Examples

Embodiment 1

[0067] Example 1 : 15.0% cuprous oleate, 12.0% zinc diamyl dithiocarbamate, 10.0% 4.4-methylene bis(dibutyl dithiocarbamate), 10.0% polydecene synthetic oil, 1.8 The ppm siloxane defoamer and the rest of the hydrogenated naphthenic oil are physically mixed in the liquid phase as a refrigeration energy-saving synergist.

[0068] Table 1

[0069]

[0070] It can be clearly seen from Table 1 that using the composition of the present invention: the temperature of the air outlet is significantly reduced; the average temperature difference between the inlet and outlet water is increased; the noise of the unit is significantly reduced, and the power saving rate calculated by the power saving rate evaluation method is 21%.

[0071] Note: Evaluation method of electricity saving rate - comprehensive electricity longitudinal comparison method (comparison of electricity consumption before and after using the energy-saving synergistic composition).

[0072] The formula for calculating...

Embodiment 2

[0078] Example 2 : 12% copper oleate, 8% copper dibutyl dithiocarbamate, 12% N,N-dipentyl dithiocarbamate, 11% PAO6, 2.5ppm silicone defoamer, The remainder of the hydronaphthenic oil is physically mixed in the liquid phase.

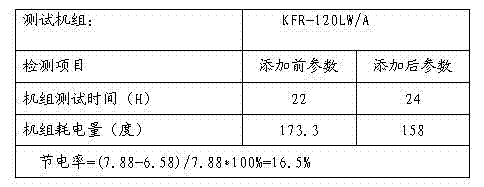

[0079] Table 2

[0080]

[0081] It can be seen from Table 2 that after adding the refrigeration energy-saving efficiency synergistic composition of the present invention, the electricity saving rate is 16.5%.

Embodiment 3

[0082] Example 3 : 14% lithium 12-hydroxystearate, 7% cadmium diamyl dithiocarbamate, 8% 6-bromo-1-(N,N-dibutyldithiocarbamate), 6 %PAO8, siloxane defoamer with a concentration of 2.0ppm and the rest of the hydrogenated naphthenic oil are mixed in the liquid phase (all components are percentages by mass).

[0083] table 3

[0084]

[0085] It can be seen from Table 3 of this embodiment that in addition to the energy-saving effect, the beneficial effect of current reduction is also obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com