Continuous film coating device and film coating process thereof for inner wall of outer glass tube of solar heat collecting tube

A technology of solar collector tube and outer glass tube is applied in the field of solar collector tube, which can solve the problems that the heat collection effect cannot reach the best state, the reflector does not work too much, the reflector is easy to accumulate dust, etc., and the vacuuming time can be reached. Reduce, reduce requirements, ensure the effect of coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

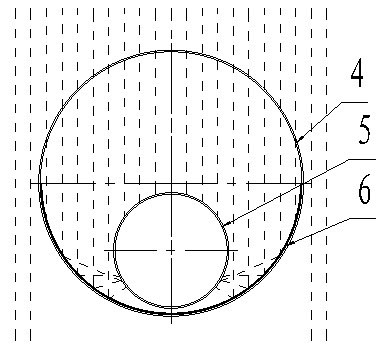

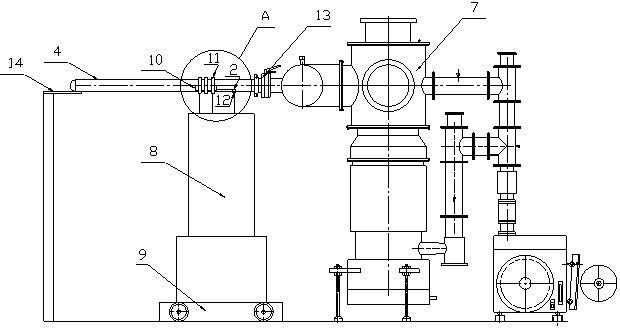

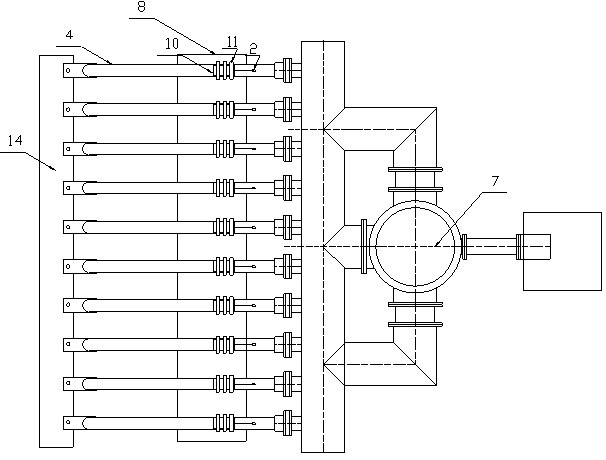

[0033] figure 1 , 2 Among them, the vacuum device 7 and the high-frequency device 8 are a one-to-one structure, and there are ten stations, the reflective film layer 6 is an aluminum reflective film, the diameter of the outer glass tube 4 is 80 mm, and the main pump of the vacuum device 7 is Oil diffusion pump.

[0034] figure 2 The shown side view of the glass tube inner wall coating device includes a coating device 10 , a high frequency device 8 , a vacuum device 7 , a mobile trailer 9 and a glass tube support device 14 . The vacuum device 10 is connected to the nozzle end of the outer glass tube 4 through the glass tube locking device 13 thereon, the round end of the outer glass tube 4 is provided with a glass tube support device 13, and the bottom of the outer glass tube 4 is provided with a The connected movable high-frequency device 8 has a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com